High-efficiency PEW250×1000 European-style jaw crusher delivers outstanding performance

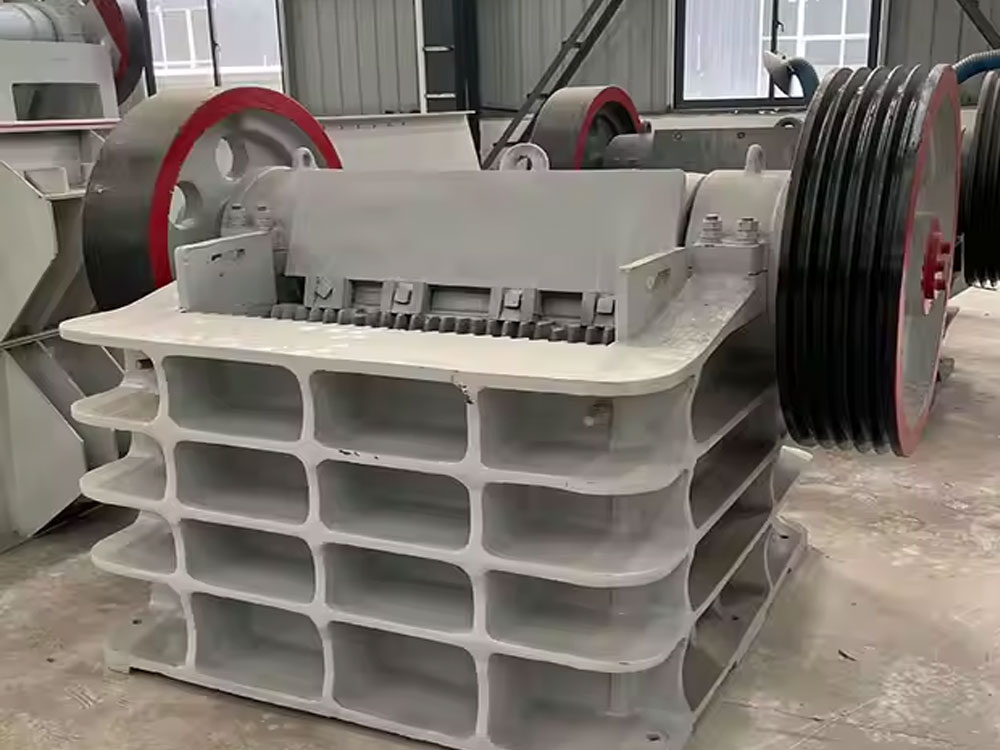

The PEW250×1000 European-style jaw crusher is an advanced machine specifically designed for high-intensity crushing operations. It is suitable for processing medium-hard to ultra-hard materials in mining, construction, metallurgy, and other industries. Its core advantage lies in its internationally leading modular design, featuring an integral cast steel bearing housing and forged steel eccentric shaft, significantly enhancing equipment stability and durability. Featuring a feed opening of 250mm × 1000mm, it handles maximum feed sizes up to 210mm with an output range of 25-60mm. Operating at 10-40 t/h capacity and powered by a 37kW motor, it delivers high efficiency with low energy consumption. This model is specifically optimized for hard materials like basalt and granite, handling compressive strengths up to 280MPa. It is widely used in high-standard projects such as highways and railways for aggregate production. Its V-shaped deep cavity design, where the movable jaw plate protrudes 80-250mm beyond the fixed jaw, effectively prevents material jamming and enhances crushing efficiency. Combined with a wedge-type discharge opening adjustment mechanism, it offers user-friendly operation and lower maintenance costs than traditional models.

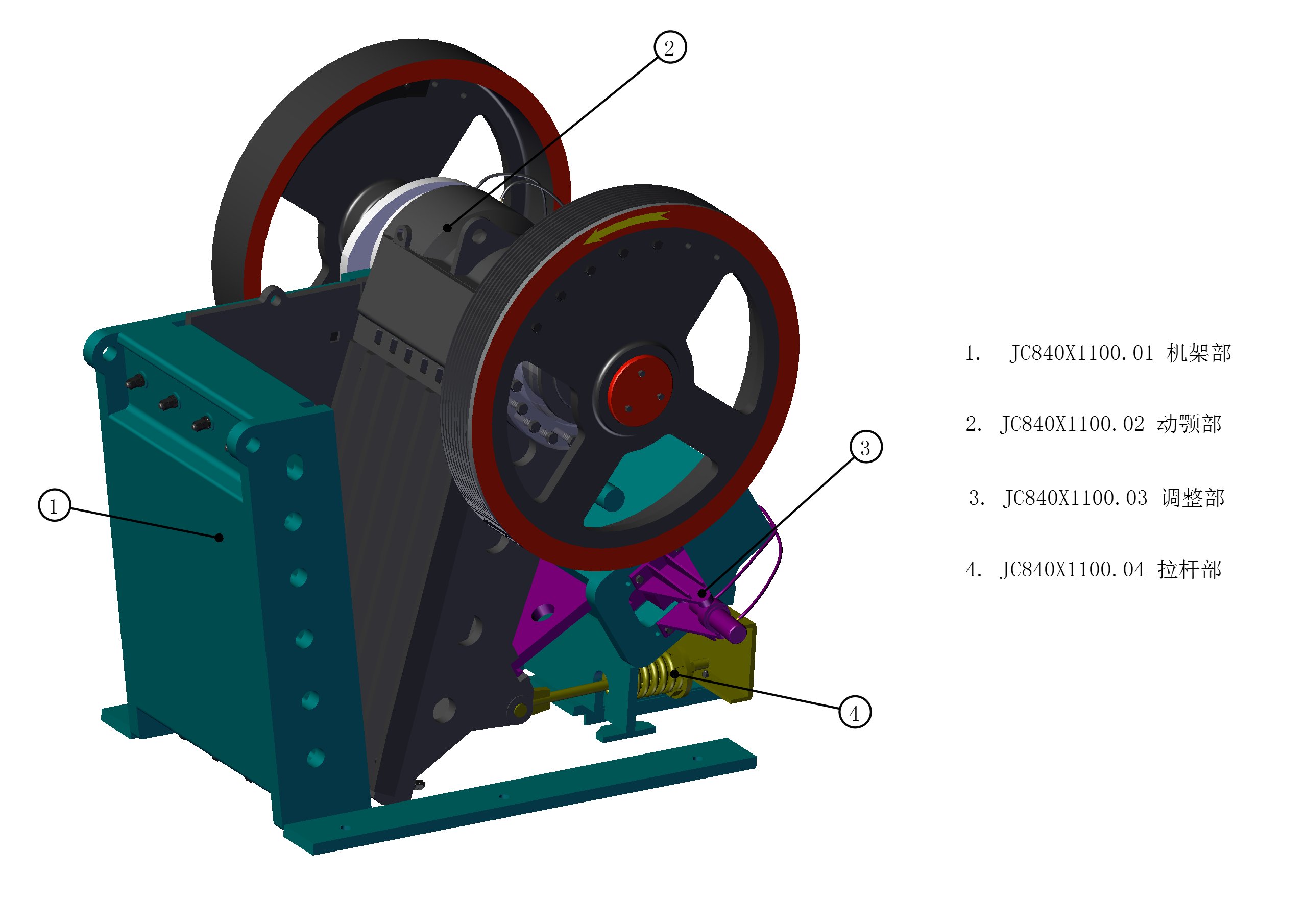

The core structure of the PEW250×1000 European-style jaw crusher adopts a modular design concept, with all key components strength-optimized. The movable jaw assembly is integrally cast from high-strength cast steel, paired with a heavy-duty forged steel eccentric shaft to ensure fatigue resistance under high-pressure crushing conditions. The symmetrical V-shaped crushing chamber features a movable jaw plate top elevated 80-250mm above the fixed jaw, creating a stepped interlocking structure that extends effective crushing length while optimizing material flow angles to prevent blockages. The bearing housing employs an integral cast steel structure with precision-fit frame integration. A labyrinth seal system combined with centralized lubrication significantly extends bearing life and reduces maintenance frequency. The discharge opening adjustment mechanism innovatively utilizes a hydraulic wedge system, achieving over 3 times the efficiency of traditional shim-type adjustments while supporting stepless particle size adjustment. The equipment features rubber vibration dampers and an overload protection system. The frame structure, optimized through finite element analysis, can withstand impact loads of 280 MPa. All transmission components employ high-precision gear meshing. The moving jaw's motion trajectory, optimized through dynamic simulation, increases horizontal stroke by 15% while reducing liner wear rates.

The PEW250×1000 European-style jaw crusher demonstrates significant technical advantages in performance. Its V-shaped deep cavity combined with a stepped jaw plate design increases the movable jaw's horizontal stroke by 15%, boosting crushing efficiency by over 30% compared to traditional models. By optimizing the movable jaw's motion trajectory, materials undergo layer compression crushing within the chamber, achieving over 90% uniformity in final particle size and significantly reducing over-crushing. Driven by a 37kW motor, energy consumption is reduced by 20%. When processing hard rock, liner plate lifespan extends to over 600 hours. The hydraulic discharge adjustment system completes particle size adjustments within 5 minutes. Combined with overload protection, equipment failure rates drop to one-third of traditional models. Specifically designed for highly abrasive materials like basalt, the machine employs composite tooth plates made of high-manganese steel and alloy steel, doubling wear resistance. This reduces overall operating costs by 40% compared to cone crusher combinations. Equipment noise is controlled below 85 decibels, and it features a pulse dust removal interface to meet environmental production requirements.

High-efficiency PEW250×1000 European-style jaw crusher delivers outstanding performance Applications

Advanced Applications in Mining Operations

1. Metal Mining Scenarios

Iron Ore Processing: For hard ore bodies like magnetite and hematite (compressive strength 250-280 MPa), high-manganese steel composite tooth plates achieve a crushing ratio of 6:1. This reduces -300mm raw ore to under 50mm in a single pass, meeting grinding mill feed requirements.

Copper Ore Crushing: In porphyry copper mining, the hydraulic overload protection system effectively prevents over-crushing of brittle minerals like chalcopyrite, boosting metal recovery by 12%.

Gold Ore Application: Equipped with a pulse dust collection system, processing gold-bearing quartz veins achieves dust concentrations ≤10mg/m³, meeting environmental standards for precious metal extraction.

2. Non-Metal Mining Solutions

Granite Processing: V-shaped deep cavity design reduces basalt crushing energy consumption to 1.2 kW·h/t, achieving ≥85% cubical particle content in final product.

Limestone Preparation: For metallurgical limestone, stepped tooth plate design increases yield of high-quality material (CaO content ≥54%) by 30%.

Quartzite Processing: Sealed bearing housing prevents silica dust ingress, enabling 8,000 hours of continuous operation without major maintenance in 7 Mohs hardness stone mines

3. Coal Mine Crushing Optimization

Raw Coal Pre-processing: Explosion-proof motor configuration (ExdⅡBT4) adapts to underground environments, achieving ≤200mm particle size at 40t/h throughput

Coal gangue utilization: Hydraulic adjustment system enables precise 15-100mm particle size control, achieving 92% qualified gangue brick raw material rate

Innovative Applications in Construction & Building Materials

1. Sand & Aggregate Production

High-speed rail aggregates: Mechanically produced 25-30mm sand via laminar crushing principle, with ≤5% needle/flake content meeting CRTS Type III track slab aggregate standards

Recycled Aggregate: “Jaw crusher + impact crusher” combined process for construction waste treatment, with recycled aggregate crushing value ≤28%

2. Concrete Production

Green Mixing Plant: Crushed limestone powder replaces 30% cement usage, reducing concrete carbon footprint

Special Concrete: 60mm basalt aggregate supplied for nuclear power projects, with radioactivity indicators compliant with GB 6566 standard

Specialized Solutions for Energy & Chemical Industries

1. Power Plant Desulfurization Systems

Limestone Preparation: Crushed -325 mesh desulfurization agent ≥90%, boosting SO₂ absorption efficiency to 98.5%

Gypsum Processing: Hydraulic adjustment system enables precise 50-100mm particle size control, meeting FGD system requirements

2. Chemical Raw Material Processing

Phosphate Ore Crushing: Specialized anti-corrosion coating for fluoride-containing ores extends equipment lifespan by 3x

Potash Preparation: Enclosed design prevents Cl₂ corrosion, achieving 5 years of continuous, trouble-free operation at Qinghai salt lake mines

Custom Infrastructure Engineering Services

1. Hydraulic Engineering

Dam Aggregate: Supplied 150-200mm graded stone for Wudongde Dam with porosity ≤45%

Slope Protection Material: Produced 30-50mm cobble substitute with roundness coefficient ≥0.8

2. Transportation Engineering

High-Speed Rail Ballast: Granite crushing meets TB/T 2322.1-2012 gradation curve standards

Highway Modifier: 40-70mm basalt aggregate achieves Grade 5 adhesion with asphalt

High-efficiency PEW250×1000 European-style jaw crusher delivers outstanding performance Advantages

Modular Frame

This equipment features an innovative non-welded, disassemblable frame design. In traditional equipment, frames typically employ welding processes. While this method ensures structural integrity, it poses significant challenges in complex underground environments: localized damage makes repairs and replacements extremely difficult, and transportation becomes highly inconvenient. In contrast, this equipment ingeniously connects its side panels and front wall panel via cylindrical pins. This connection method not only simplifies installation, significantly reducing underground setup time and improving efficiency, but also allows the frame to be disassembled into multiple sections for transportation. This facilitates handling and loading, effectively lowering transportation costs and risks. Additionally, the cylindrical pin connection enhances structural reliability. During operation, it better withstands external forces and vibrations, ensuring stable equipment performance.

V-Shaped Deep Cavity Structure

The equipment's unique V-shaped deep cavity structure is key to its enhanced crushing efficiency. The movable jaw plate rises 80–250 mm above the fixed jaw, forming a stepped interlocking structure. During crushing, materials entering the chamber are progressively compressed and broken along the V-shaped deep cavity. This stepped interlocking mechanism ensures materials receive more uniform and thorough crushing forces, substantially boosting crushing efficiency—a 30% improvement over traditional designs. Simultaneously, this design effectively minimizes material blockage, ensuring continuous and stable equipment operation.

High-Efficiency Crushing Capability

This equipment possesses formidable high-efficiency crushing capabilities, effortlessly processing hard rock with compressive strengths ≤280MPa, such as basalt and granite. These hard rocks are characterized by high hardness and toughness, often rendering traditional crushing equipment inefficient and prone to damage when processing them. Through its unique structural design and advanced crushing technology, this equipment achieves high production capacity—reaching 10–40 t/h—while maintaining crushing quality. This makes it highly applicable in mining operations, construction aggregate processing, and other fields.

Low Maintenance Costs

To reduce maintenance expenses, the equipment incorporates labyrinth seals and a centralized lubrication system. The labyrinth seals effectively prevent dust and impurities from entering bearings, minimizing wear and corrosion while extending bearing lifespan. The centralized lubrication system automatically and uniformly supplies lubricant to all critical points, eliminating equipment failures caused by insufficient or uneven lubrication. Simultaneously, the wear resistance of the liner plates has been significantly enhanced. Compared to traditional equipment, the wear resistance of the liner plates has doubled, reducing the frequency of liner plate replacements and further lowering equipment maintenance costs.

Reduced Energy Consumption

In today's era of increasingly tight energy resources, reducing equipment energy consumption is a key pathway to improving corporate economic efficiency. This equipment incorporates advanced energy-saving technology. Driven by a 37kW motor, its energy consumption is reduced by 20% compared to traditional models. This not only lowers electricity costs for enterprises but also aligns with national energy conservation and emission reduction policies, delivering significant social and environmental benefits.

Lower Overall Costs

Compared to cone crusher combination solutions, this equipment offers lower overall costs during long-term operation. Cone crusher combinations typically require multiple units working in tandem, entailing high equipment acquisition costs, large footprints, and elevated maintenance expenses. This integrated unit, however, combines multiple functions into one compact design. Its lower purchase price, smaller footprint, and combination of low maintenance costs with high production capacity result in long-term operational costs 40% lower than cone crusher combinations, delivering substantial savings for enterprises.

High-efficiency PEW250×1000 European-style jaw crusher delivers outstanding performance Works Principle

As the movable jaw rises driven by the eccentric shaft, the angle between the toggle and the movable jaw gradually increases. The toggle supports and transmits the force of the movable jaw's motion. With the increasing angle, the toggle pushes the movable jaw plate closer to the fixed jaw plate. At this point, material is fed into the crusher's V-shaped deep cavity, measuring 250×1000mm. Its unique V-shaped structure enables optimal material accumulation and flow within the cavity.

As the movable jaw plate approaches the fixed jaw plate, the material undergoes dual compression from both plates. Simultaneously, since both the moving and fixed jaw surfaces are equipped with toothed plates, the interaction between these plates produces a grinding effect on the material. This combined force of compression and grinding rapidly crushes the material within the crushing chamber, reducing large chunks into smaller particles.

When the movable jaw descends driven by the eccentric shaft, the angle between the toggle and the movable jaw gradually decreases. At this point, the spring tie rod comes into play, utilizing its elastic force to rapidly return the movable jaw to its original position, gradually increasing the distance between the movable jaw plate and the fixed jaw plate. During the downward and return motion of the movable jaw, the crushed material is discharged from the crusher through the discharge opening under the force of gravity.

The discharge opening size of this crusher can be adjusted within a range of 25-60mm. This adjustability enables the equipment to produce products of different particle sizes according to varying production requirements. Moreover, adjusting the discharge opening is extremely convenient. Through the hydraulic wedge system, particle size adjustments can be completed within 5 minutes, significantly enhancing production flexibility and efficiency.

High-efficiency PEW250×1000 European-style jaw crusher delivers outstanding performance Technical Parameters

| Feed opening size | 250×1000 mm | Maximum feed size | 220 mm |

| Adjustment Range of Discharge Port | 20-40 mm | processing capacity | 15-50 t/h |

| Rotational speed | 330 r/min | Power | 30 kw |