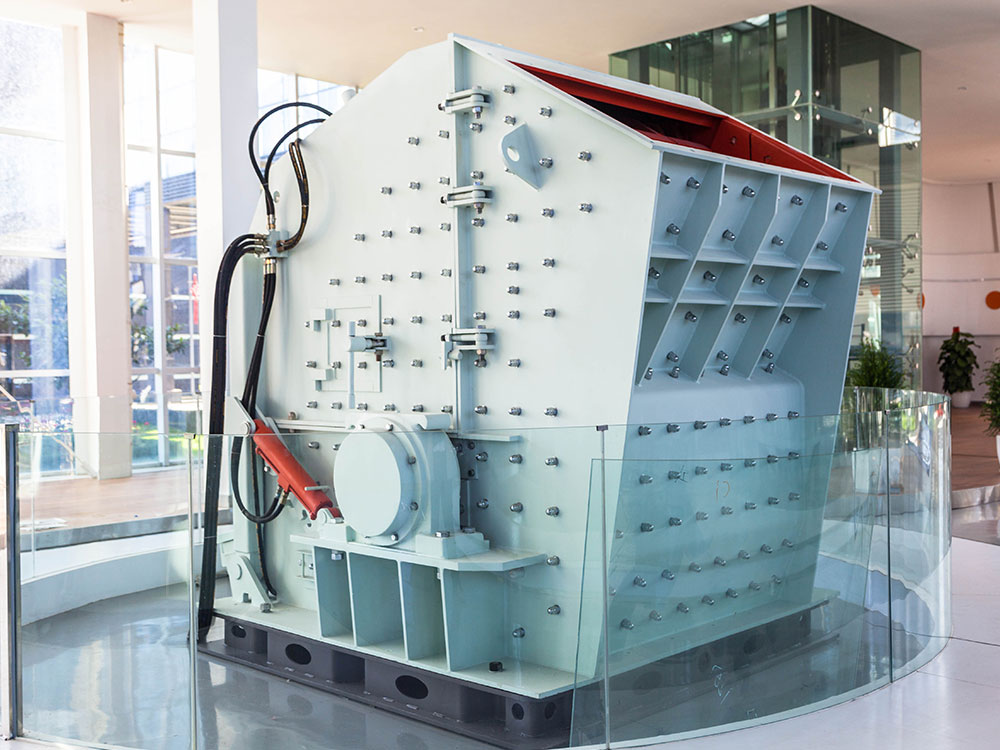

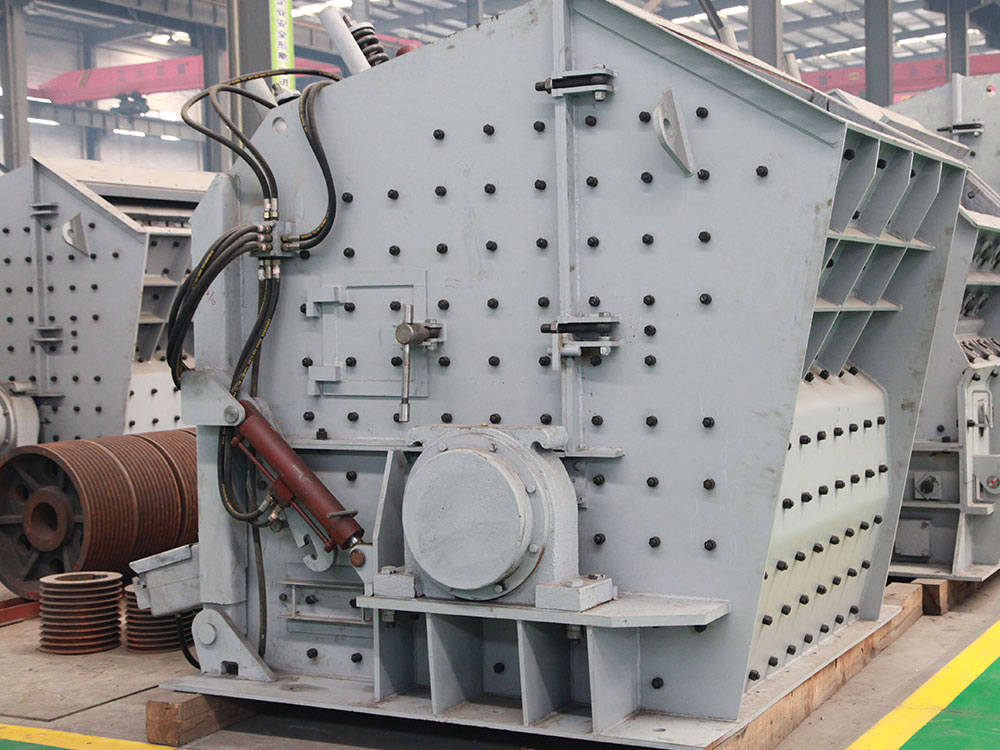

High performance B6150SE impact crusher for sale

The B6150SE impact crusher is used in aggregate and mineral processing worldwide, with thousands of units installed to prove its cost-saving, durability and ability to handle a wide range of complex applications. These tasks range from producing high-quality aggregates and sands to heap leach materials, pre-grinds and finished industrial mineral products. The B6150SE has so many advantages because its designers listened carefully to the needs of customers. This philosophy has led to the user-friendly VSI crusher, which ensures the lowest cost per ton by optimizing energy efficiency, reducing wear, extending maintenance intervals, shortening repair times and improving crushing performance and control. As an excellent third or fourth stage reduction unit, the B6150SE has demonstrated its unique ability to operate in a variety of demanding and variable crushing operations in applications such as construction, industrial minerals, metal minerals and waste recycling. This is due to its unique free impact crushing and grinding mechanism, as well as the ability to fine-tune the process by simply adjusting the rotor speed or cascade ratio.

High performance B6150SE impact crusher Applications

Construction Industry: B6150SE impact crusher can crush building materials such as concrete, stone, bricks, etc., meeting the construction industry's demand for aggregates and sand.

Mining Industry: The equipment is suitable for crushing various ores, such as coal, metal ores, etc., providing high-quality crushing solutions for the mining industry.

Cement Industry: B6150SE impact crusher can process cement raw materials such as limestone, coal, slag, etc., to help cement production.

Environmental Protection Industry: The equipment can effectively crush construction waste and waste, promote resource recycling, and meet environmental protection requirements.

Other Industries: In addition, B6150SE impact crusher is also widely used in stone production lines in industries such as hydropower and highways, showing its powerful crushing ability.

High performance B6150SE impact crusher Advantages

Efficient crushing

It can handle materials of various hardnesses, has high crushing efficiency, significant crushing ratio, and the resulting product has uniform particle size and an approximately cubic shape, making it widely applicable to a variety of industrial fields.

Compact design

Simple structure, small space occupation, light weight, easy for daily maintenance and operation, helping to reduce overall operating costs.

Low energy consumption operation

The motor is powerful, consumes little energy, and exhibits excellent energy-saving effect, which not only reduces production costs, but also contributes to environmental protection.

Green and energy saving

Environmentally friendly materials are selected to effectively control pollution, and dust emissions meet standards to achieve a green and low-energy consumption production model.

Convenient maintenance

Parts can be replaced quickly and the maintenance process is simple, which greatly reduces maintenance time and costs and improves equipment usage efficiency.

Wide applicability

Whether it is soft or hard materials, or even high-humidity materials, it can be processed efficiently, effectively prevent clogging, and has strong adaptability.

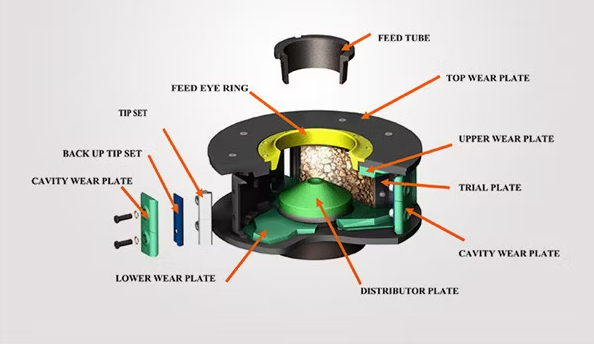

High performance B6150SE impact crusher Principle

In the "stone-on-stone" crushing method, the feed material is crushed by itself inside the machine, and the resulting product has uniform particle size, good cubic shape and low water content. The operation process is briefly described as follows: the material is fed into the crusher from the feed port, and first screened by the screen plate, the fine particles are separated, and the large particles enter the crushing chamber under the guidance of the joint screen system. In the crushing chamber, the plate hammers on the high-speed rotating rotor give the material an initial violent impact. After that, these crushed materials fly to the impact plate at a very high speed and undergo secondary crushing. The material bounces continuously between the impact plate and the hammer head, and during this process, the materials also collide with each other and further refine. When the particle size of the material is reduced enough to pass through the gap between the hammer head and the impact plate, it will enter the next crushing chamber for further crushing until it reaches the required particle size and is then discharged from the bottom of the equipment. The particle size of the final product can be easily adjusted by adjusting the distance between the lower edge of the impact plate and the plate hammer.

High performance B6150SE impact crusher Technical Parameters

| Feature | High Efficiency | Specification | Standard |

| Warranty | 6 Months | Origin | Anhui China |

| Advantage | Easy to Maintenance | Customized | Customized |

| Production Capacity | 10000PCS Per Year | Transport Package | Custiomized |