High performance NP20 impact crusher for sale

The NP20 impact crusher introduces innovative design concepts to allow feed materials to penetrate deeper into the rotor more smoothly. This design change not only greatly improves the crushing efficiency, but also reduces the impact of plate hammer wear on the discharge curve, ensuring the consistency of the final product particle size. In addition, the crusher's maximum power has been upgraded to 630 kW (800 hp), significantly enhancing its productivity and making it capable of handling large-scale materials. The NP20 impact crusher also provides a variety of blow hammer materials including manganese steel, martensitic steel, high chromium iron and ceramic inserts for users to choose from to meet the needs of different abrasive materials. Together with a system designed specifically for the NP20, long-term profitability is further enhanced by optimizing crusher control and accurately displaying performance parameters. Its rotor rotation system (SRR) is the key to adjusting the discharge port and replacing the plate hammer, and brings higher safety to maintenance.

High performance NP20 impact crusher for sale Applications

In the mining industry, the NP20 impact crusher has become the core force in the ore crushing process with its excellent performance and stable performance. Its high crushing ratio and excellent crushing efficiency allow ore to be easily broken into smaller particle sizes, which brings great convenience to subsequent mineral processing, smelting and other processes. This crusher not only significantly increases the processing speed of ore, but also ensures a highly consistent particle size of the crushed ore, laying a solid foundation for subsequent processing. In all aspects of mining, the NP20 impact crusher has won wide recognition and praise from users for its excellent performance.

In the construction field, the NP20 impact crusher also shows its strong strength and value. It can efficiently process construction waste, waste concrete and other materials, converting these wastes into valuable recycled aggregates. After further processing, these recycled aggregates can produce new building materials, such as recycled concrete, recycled bricks, etc., realizing the effective reuse of resources and greatly reducing the environmental pollution of construction waste, truly realizing green environmental protection and The organic combination of sustainable development.

In the construction of infrastructure such as roads and railways, the NP20 impact crusher plays a decisive role. Its powerful crushing capacity and stable and reliable performance make it perform well in processes such as stone processing and roadbed filling. Especially in the roadbed filling process, the high-quality filler provided by the NP20 impact crusher provides a strong guarantee for the solidity and stability of roads and railways. These fillers have uniform particle size and hard texture, fully complying with the high-quality material requirements for infrastructure construction.

High performance NP20 impact crusher for sale Advantages

High crushing ratio

The impact crusher is famous for its high crushing ratio, and the NP20 impact crusher has taken this feature to a new level. It can not only efficiently process soft materials such as limestone, but also easily cope with medium-hard materials such as quartz and dolomite. This wide applicability makes the NP20 impact crusher stand out among many crushing equipment and become the first choice for many industry users.

Energy saving and environmental protection

The NP20 impact crusher shows its dual advantages of environmental protection and energy saving during the crushing process. Low noise and less dust not only meet the strict requirements of modern industry for environmental protection, but also provide operators with a more comfortable and healthy working environment. At the same time, its efficient crushing performance not only means higher production efficiency, but also directly leads to reduced energy consumption and reduced operating costs. Such equipment is undoubtedly the ideal choice pursued by many industry users.

Easy maintenance

By adopting a new detachable impact plate module, users can easily and safely replace the impact plate liner from the outside without disassembling the internal structure of the crusher, which undoubtedly greatly improves maintenance efficiency and reduces downtime. The design of the new maintenance bridge provides safer and more convenient access for the replacement of the hammer and the highest side guard, making maintenance work more handy.

Reduce plant operating costs

Long-term crushing experience and continuous cooperation with customers and research laboratories have brought technological innovations and improved the reliability of the NP20 crusher. Durable wear parts and mechanical components reduce maintenance costs. In addition, as long as the tertiary crushing stage can be avoided, capital costs and energy requirements will be significantly reduced.

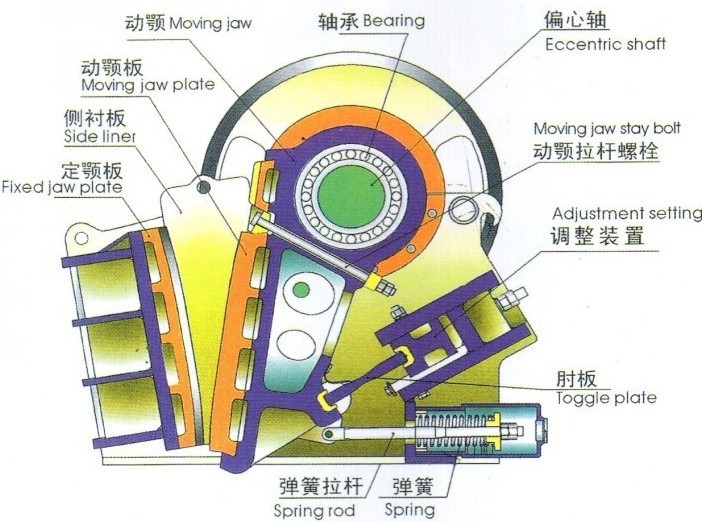

High performance NP20 impact crusher for sale Working Principle

The raw materials are loaded into the feed port of the crusher and fed into the crushing chamber by belt conveyor or other mechanical equipment. During the feeding process, screening and pretreatment can be carried out as needed to ensure that the raw materials entering the crushing chamber are of uniform size. The raw materials entering the crushing chamber are first impacted by the hammers, crushed for the first time, and thrown to the impact plate at a high speed. The materials are crushed again on the impact plate and then rebounded back to the hammer strike area to repeat the above process. During the round trip between the hammer and the impact plate, the materials will also collide with each other, further promoting the crushing effect. When the material particle size is smaller than the gap between the hammer and the impact plate, the material can enter the next crushing chamber (if the equipment is designed with multiple crushing chambers) for further crushing, or when the material is crushed to a size smaller than the discharge port size, it is discharged from the discharge port due to its own weight. It is through this repeated impact and collision that the NP20 impact crusher crushes the material into the required particle size. This working principle makes the NP20 impact crusher perform well in processing soft and medium hard materials, with advantages such as high crushing efficiency and low energy consumption. At the same time, its structural design also fully considers the convenience of maintenance, such as the use of new detachable impact plate modules and maintenance bridges, making the maintenance of the equipment easier and more efficient.

High performance NP20 impact crusher for sale Technical Parameters

| Crushing range | Secondary and tertiary | Total weight | 26 750 kg (58 975 lbs) |

| Shaft line weight | 12 025 kg (26 510 lbs) | Rotor diameter | 1 500 mm (59 1/16") |

| Rotor width | 2 000 mm (78 3/4") | Maximum feed size | 400 mm (16") |

| Nominal installed power | 500 kW (2x250 kW) | Maximum installed power | 800 hp (2x400 hp) |