Horizontal Shaft Impact Crusher Primary Series NP1415 Crusher

The crusher integrates a heavy-duty rotor, highly wear-resistant materials and an optimized crushing chamber design. The NP1415 model is specially equipped with an innovative blow bar connection mechanism, which effectively reduces the possibility of blow bar breakage by achieving precise blow bar arrangement on the contact surface of the crossbeam, and enables the application of cast iron in blow bar to break through traditional limitations. This stable rotor structure further improves crushing efficiency, ensures smooth operation, reduces energy consumption, and enhances long-term operating performance. In addition, the crusher provides a variety of configuration options to simplify the installation process. For different types of processed materials, we also provide a variety of wear-resistant parts to choose from, regardless of the abrasiveness of the material, to meet the needs. The automatic calibration function can adjust the crusher settings according to actual needs, such as controlling the discharge curve, and can flexibly respond even to highly abrasive materials.

Horizontal Shaft Impact Crusher Primary Series NP1415 Crusher Applications

In the aggregate and mining industry, the NP1415 crusher stands out for its unparalleled crushing performance. Whether it is coarse crushing, medium crushing or fine crushing, the NP1415 crusher can complete it with ease. Its powerful crushing capacity and precise particle size control make it an ideal choice for handling various hardness and abrasive materials. In the mining process, the NP1415 crusher can efficiently crush various ores and provide high-quality raw materials for subsequent processing. In aggregate production, it can produce aggregates that meet different particle size requirements to meet the demand for high-quality aggregates in construction, roads and other fields. In addition to the aggregate and mining industry, the NP1415 crusher also plays an important role in the recycling industry. With the improvement of environmental awareness and the promotion of resource recycling, the recycling industry has received increasing attention. With its efficient crushing capacity, the NP1415 crusher can easily handle various waste materials, such as scrap metal, plastic, glass, etc., and crush them into granular materials that can be used for reproduction. This not only helps to reduce environmental pollution, but also achieves effective utilization of resources and promotes sustainable development.

Horizontal Shaft Impact Crusher Primary Series NP1415 Crusherr Advantages

High crushing ratio

High crushing ratio is one of the distinguishing features of this equipment. The crushing ratio refers to the ratio of the raw material particle size to the crushed product particle size. A high crushing ratio means that the equipment can crush the material to a smaller particle size in a shorter time. This feature is particularly prominent when handling soft and medium-hard materials. For example, in the mining industry, hard rocks need to be broken into smaller particles for subsequent processing, and equipment with a high crushing ratio can obtain a more ideal particle size distribution while ensuring efficiency. In addition, in the chemical and pharmaceutical industries, the crushing processing of soft raw materials also requires high precision and high efficiency, and this equipment can also easily handle it.

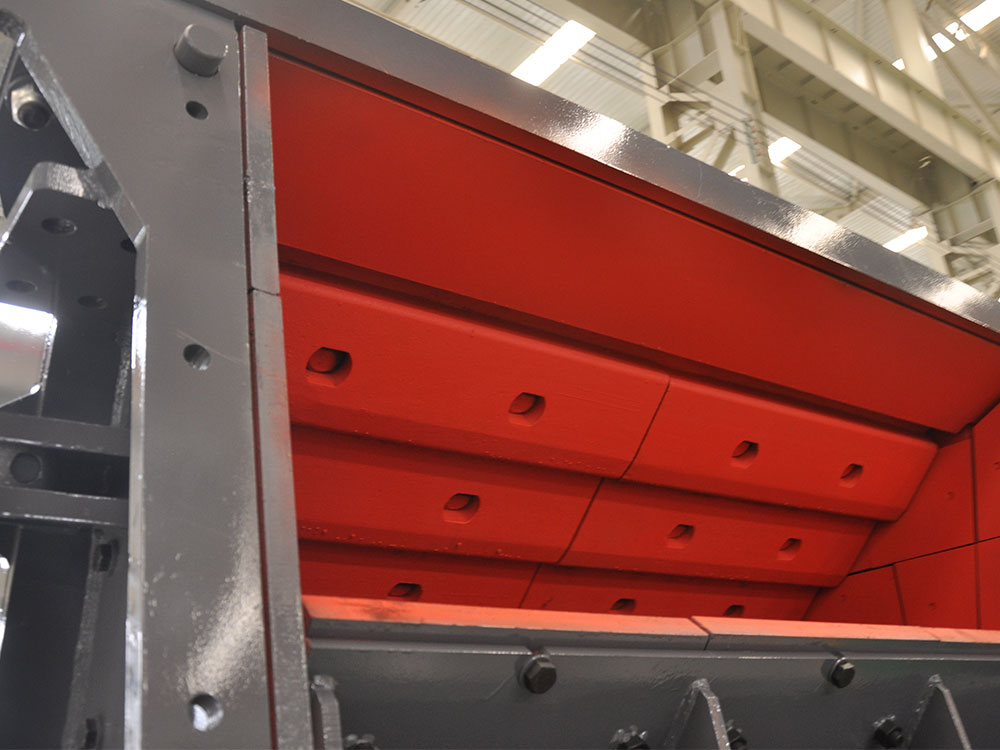

Large feed opening and high crushing cavity

In addition to the high crushing ratio, the design of the feed port and the height of the crushing chamber are also significant advantages of this equipment. The large feed opening means the equipment can handle large pieces of material easily, eliminating the need for frequent shutdowns for manual crushing or adjustments. This is of great significance for improving production efficiency and reducing labor costs. At the same time, the height design of the crushing cavity allows the materials to have enough space to fully impact and squeeze during the crushing process, thus improving the crushing effect. This design is particularly suitable for handling materials with high hardness and large lumps, such as concrete blocks in construction waste and large rocks in mining.

Grid size is adjustable and product granularity is controllable

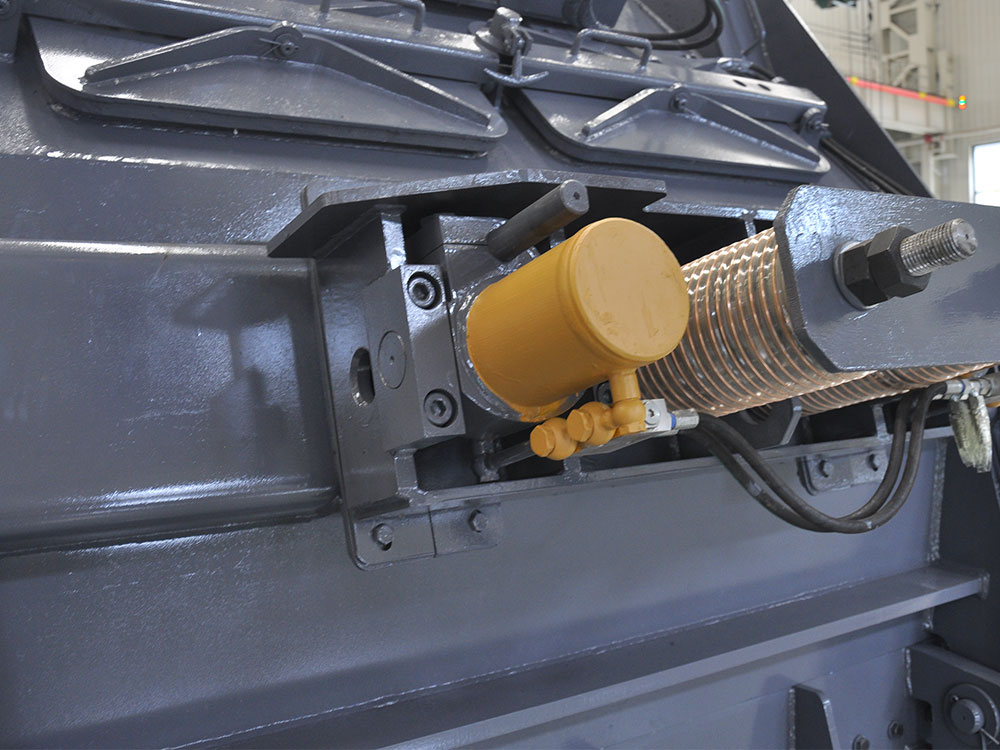

In order to meet the needs of different users for product granularity, this device is also equipped with an adjustable grid. Adjustment of the grid size can precisely control the particle size range of the crushed products to meet the individual needs of users. Whether it is the chemical industry that requires fine particles or the construction industry that requires larger particles, it can be achieved by adjusting the grid size. In addition, the adjustable grid also ensures the uniformity and consistency of the particle shape after crushing, which is of great significance for improving product quality and reducing subsequent processing costs.

Horizontal Shaft Impact Crusher Primary Series NP1415 Crusher Principle

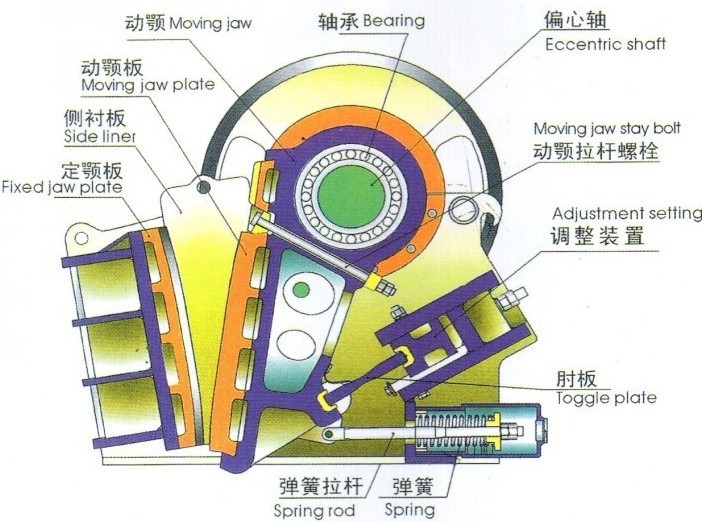

The working principle of NP1415 crusher is mainly based on impact energy to crush materials. Driven by the motor, the rotor rotates at high speed, and the materials enter the crushing chamber and are crushed by the high-speed impact of the hammer on the rotor. Subsequently, the crushed materials are thrown to the impact device for further crushing, and this process is repeated until the materials reach the required particle size and are finally discharged from the discharge port. NP1415 crusher has a large crushing ratio, especially when processing soft and medium hard materials. Its crushing chamber is reasonably designed, the product particle size is controllable, and the particle shape is good.

Horizontal Shaft Impact Crusher Primary Series NP1415 Crusher Parameters

| Crushing range | Primary | Rotor width | 1 500 mm (59 1/8") |

| Total weight | 22 330 kg (49 230 lbs) | Nominal installed power | 250 kW (350 HP) |

| Shaft line weight | 8 165 kg (18 004 lbs) | Maximum installed power | 355 kW (475 HP) |

| Rotor diameter | 1 400 mm (55 1/8") | Maximum feed size | 1 000 mm (40") |