How to choose a good quality C120 jaw crusher?

The design features of the C120 Jaw Crusher include optimised crushing chamber shape, dynamics and operating parameters that have been defined and optimised to ensure superior capacity. Its height is fully utilised, resulting in a steeper crushing chamber with a high engagement angle and an oversized linear eccentric at the bottom, resulting in higher throughputs and greater crushing ratios. In addition, the C120 jaw crusher is very easy to install, and it offers various options such as on-board motor base, flywheel and drive composite guards, making the installation process more flexible and convenient. Overall, the C120 Jaw Crusher plays an important role in the mining and stone processing industries due to its high efficiency, reliability and flexibility. Whether it is used for coarse crushing or other crushing sections, it ensures excellent performance and output to meet the various needs of customers.

good quality C120 jaw crusher Applications

In mining engineering, C120 jaw crusher shows extraordinary strength, which can easily crush various hard ores and rocks into suitable size particles, providing high-quality raw materials for subsequent beneficiation and smelting. Its outstanding crushing ratio and even product size undoubtedly make it win wide recognition and favour in the mining industry.

The C120 jaw crusher also shines in the construction industry. Whether it is crushing limestone, granite and other raw materials into basic materials for concrete and mortar, or converting construction waste into reusable recycled materials, it has demonstrated its excellent crushing capacity and firm support for green development.

The C120 jaw crusher is even more indispensable in road projects such as highways and railways. It can effectively crush all kinds of stone materials, whether natural rock or construction waste, into suitable particle size and gradation for road construction, providing a solid guarantee for the laying of road base and pavement.

In water conservancy project, C120 jaw crusher also plays a pivotal role. It can process a large amount of materials to meet the huge demand for sand and gravel aggregate in water conservancy projects, providing a stable and reliable supply of sand and gravel aggregate for the construction of water conservancy facilities.

In addition, in chemical production, C120 jaw crusher also shows its wide application value. It can crush raw materials such as coal, sulphur, phosphorite, etc., providing a stable and reliable supply of raw materials for chemical production, further proving its excellent performance and wide application prospects.

good quality C120 jaw crusher Advantages

Wear-resistant and durable with long life

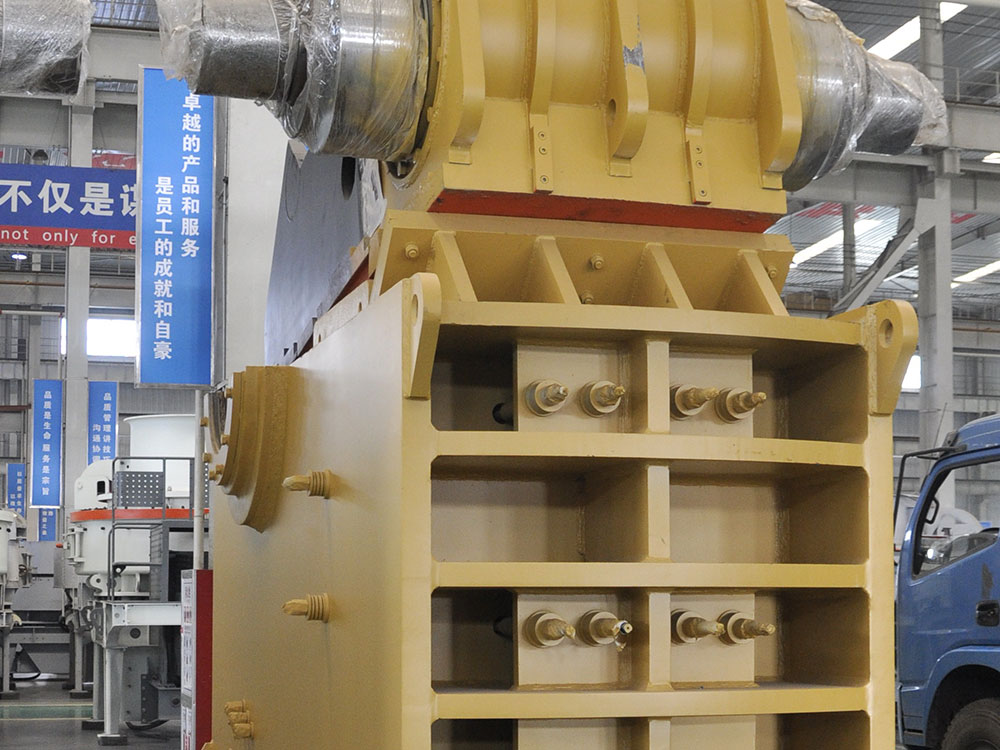

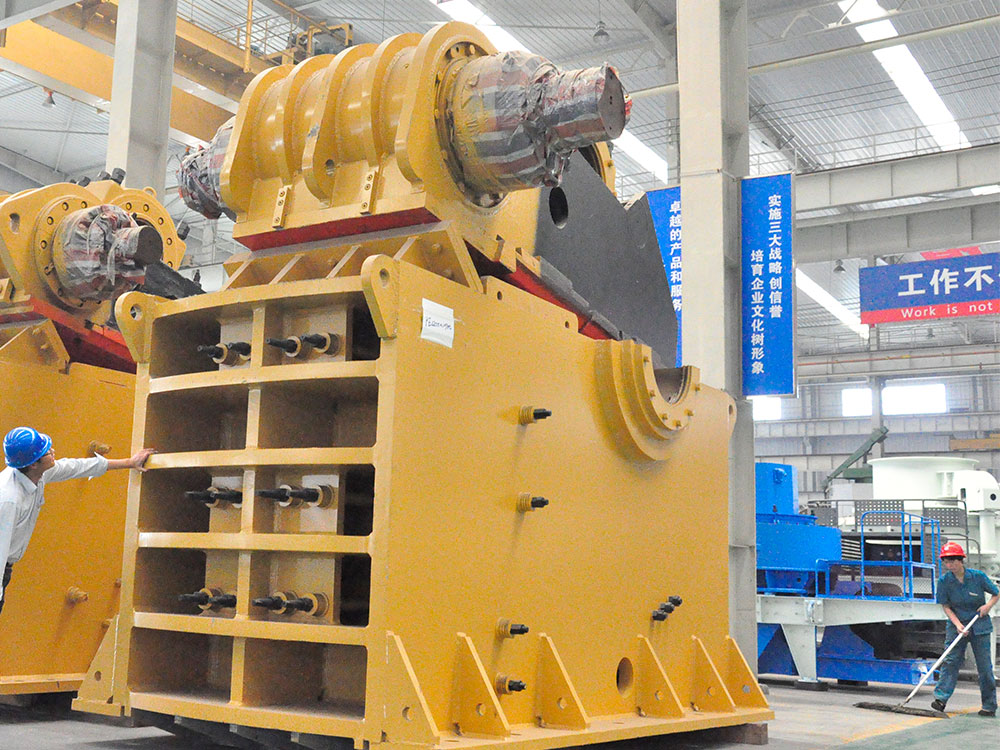

The machine's frame is cast from high-quality alloy materials for superior fatigue strength. Meanwhile, its wearing components and parts are designed for easy accessibility and replacement, reducing maintenance costs. In addition, the bottom of the crushing chamber of the C120 jaw crusher is designed with a large eccentric distance, which increases the stroke amplitude and improves the crushing ratio and capacity, and also helps to extend the service life of the equipment.

Strong adaptability and wide range of applications

The C120 jaw crusher is characterised by its small size, small footprint and strong adaptability. It can be used not only for underground mining and mobile crushing applications, but also widely used in many processing fields such as building materials, transport, and mineral processing. Whether dealing with hard rock or soft rock, this equipment can show good crushing effect.

High degree of automation and ease of operation

The C120 Jaw Crusher is equipped with an advanced automation system that allows remote monitoring and adjustment of settings. This makes the machine easier to operate and also helps to improve productivity and safety. In addition, the machine features a low vibration level and smooth operation, reducing failures caused by unstable operation.

Overload protection mechanism

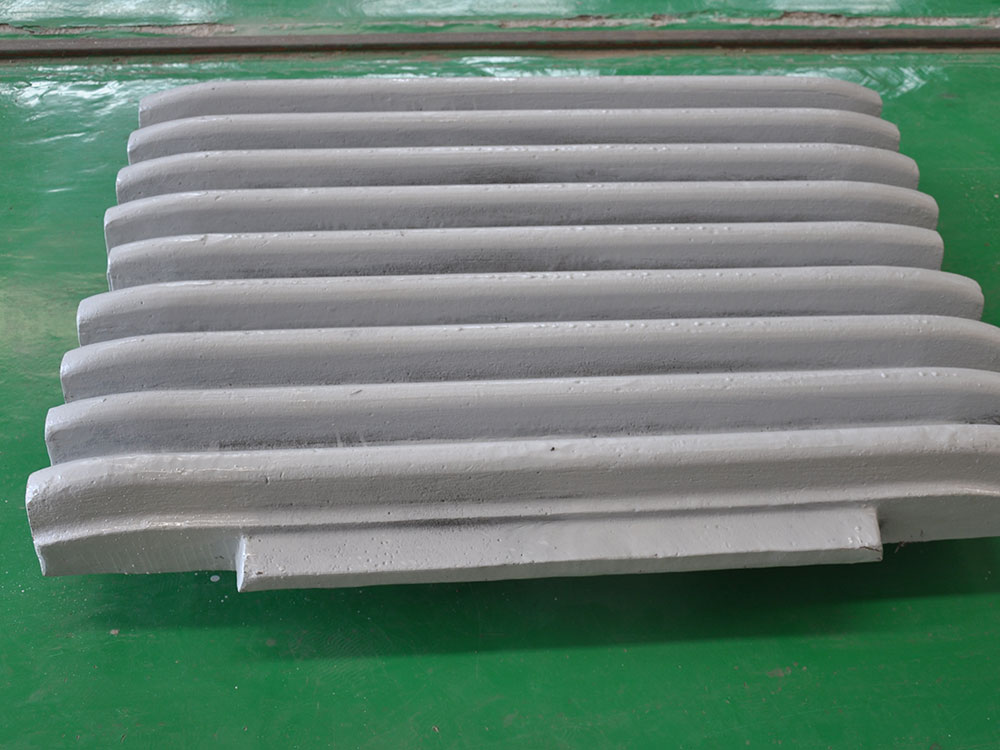

When the equipment is working, materials exceeding its crushing capacity may enter, these materials will have adverse effects on the operation of the equipment and even damage the equipment, at this time, the elbow plate will break by itself to protect the equipment from damage.

Efficient Crushing and High Capacity

C120 Jaw Crusher adopts advanced crushing chamber design and movable jaw movement to ensure that the materials are fully squeezed, split and milled in the crushing chamber, thus realising high efficient crushing. At the same time, its large feed opening and optimised discharge opening design enable the machine to handle large quantities of material and maintain high capacity.

good quality C120 jaw crusher Working Principle

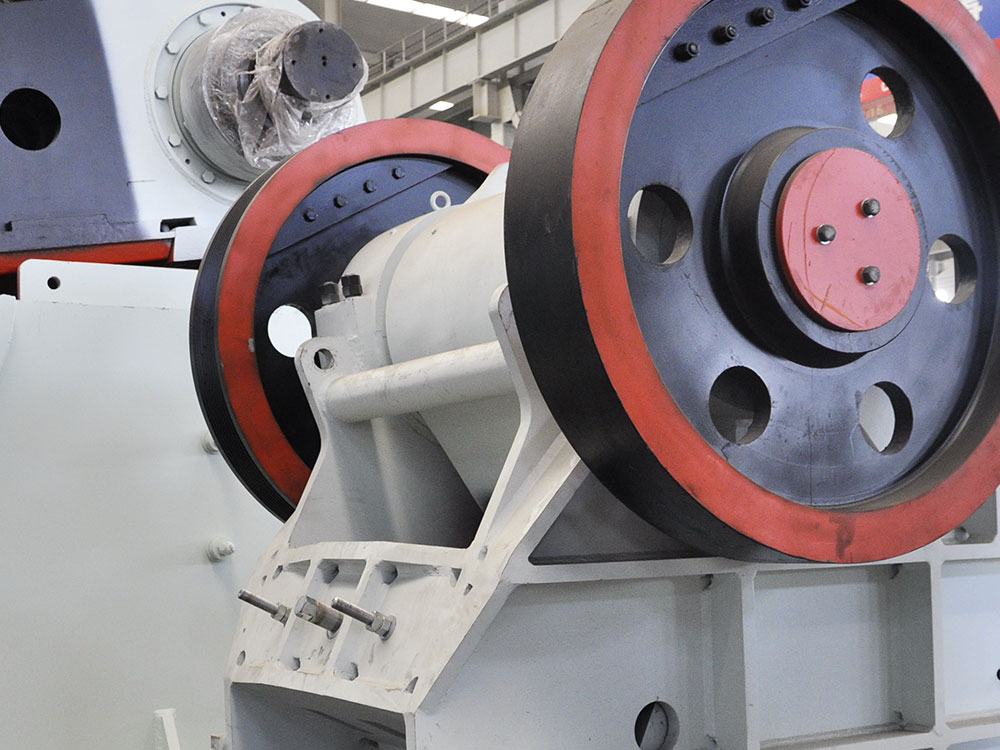

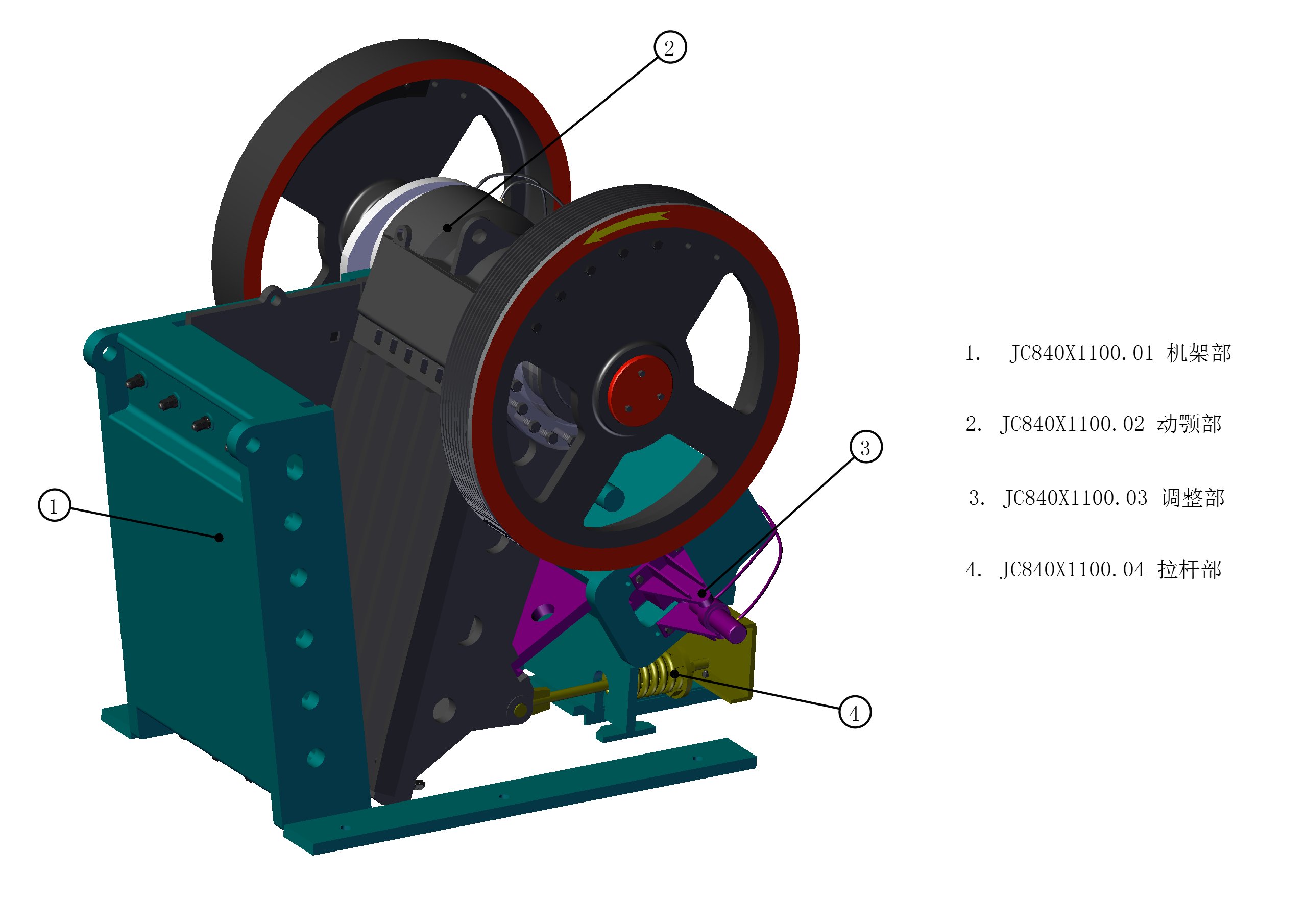

C120 Jaw Crusher, this machine consists of two main parts: the fixed jaw plate and the movable jaw plate. The movable jaw, which we usually call the movable jaw, is cleverly connected to the driving device, such as the electric motor, through the eccentric shaft. The motor drives the belt and pulley to rotate, which in turn drives the eccentric shaft to rotate, causing the movable jaw to move up and down regularly.

The material is carefully placed in the crushing chamber, which consists of the fixed jaw plate and the movable jaw plate. When the movable jaw rises, the angle between the elbow plate and the movable jaw quietly becomes larger, which pushes the movable jaw plate to approach the fixed jaw plate slowly. At this time, the material is squeezed and rubbed between the two jaw plates, and gradually broken into fine particles. When the movable jaw goes down, the angle becomes smaller, and the movable jaw plate gracefully leaves the fixed jaw plate with the assistance of the pull rod and spring. At this moment, the crushed materials, pulled by gravity, are discharged leisurely through the discharge opening at the lower part of the jaw cavity.

With the continuous rotation of the motor, the movable jaw carries out periodic up and down movement, so as to achieve continuous crushing and discharging of materials. This periodic crushing and discharging process is the key to the C120 jaw crusher's ability to efficiently process large quantities of materials. In addition, the C120 jaw crusher is equipped with an adjustable crushing chamber, which allows us to easily adjust the outlet size of the crushing chamber as needed. In this way, the size of the final product produced by the crusher can be effectively controlled to meet the individual needs of different customers.

good quality C120 jaw crusher Technical Parameters

| speed | 230 rpm | Power | 160 kW |

| Weight | 27 990 kg | width | 1 200 mm |

| depth | 870 mm | closed side | 70 mm-170mm |