How to choose a stone crusher for aggregate production? NP15 impact crusher is good

NP15 impact crusher is a piece of equipment specially built for medium and fine crushing operations. Its innovative design aims to comprehensively improve the output and operating rate of the crushing circuit, while effectively reducing recycling and reducing energy consumption. Through the exquisite design of this crusher, the feed materials can enter the rotor more deeply, thus increasing the contact area between the materials and the rotor and significantly improving the crushing efficiency.

The feeding method with a large inclination angle greatly reduces the impact of the plate hammer wear on the discharge curve, ensuring the long-term stability of the product grain shape and reducing the trouble of frequent replacement of the plate hammer. In addition, the ultra-large opening design of the new frame brings unprecedented convenience to the replacement of wearing parts. The detachable impact plate module makes it possible to safely and conveniently replace the impact plate lining from outside the crusher.

The new maintenance bridge provides a safe and reliable maintenance channel for the replacement of the blow hammer and the replacement of the highest side guard plate, further improving the maintainability of the equipment. In short, the NP15 impact crusher is undoubtedly the ideal choice for aggregate production, recycling, and the second and third crushing stages in mining production. Its efficient and stable performance has been widely verified and praised in many industrial fields.

NP15 impact crusher Applications

NP15 impact crusher has been widely used in many industrial fields due to its high efficiency and stable performance. It is mainly used in aggregate production, recycling and the second and third crushing stages of mine production. The main application areas are as follows. The first is ore crushing. In mining projects, NP15 impact crusher can crush various hard ores into particles of appropriate size, providing ideal raw materials for subsequent mineral processing and smelting. Secondly, the equipment can be used to produce various raw materials required for construction, such as crushing limestone, granite, etc. into raw materials for concrete and mortar, or converting construction waste into usable recycled materials, which promotes the green development of the construction industry. In addition, in road projects such as highways and railways, NP15 impact crusher can crush various stones for paving roadbeds and pavements, ensuring the smooth progress of road projects. In addition, in the chemical industry, the equipment can be used to crush raw materials such as coal, sulfur, and phosphate rock, providing a stable and reliable supply of raw materials for chemical production.

NP15 impact crusher Advantages

New experience of efficient crushing and stable discharge

NP15 impact crusher, with its innovative design as its highlight, leads the new trend in the crushing industry. The unique feeding method allows the material to come into deeper contact with the rotor, thus greatly improving the crushing efficiency. The design of the large-inclination feeding angle minimizes the impact of the blow bar wear on the discharge curve. The product grain shape remains stable, and you can enjoy a long-lasting crushing effect without frequent replacement of the blow bar.

Flexible configuration, excellent performance

Faced with materials of different abrasiveness, the NP15 impact crusher can handle them calmly. You can choose from manganese steel, martensitic steel or high chromium iron combined with ceramic inserts to ensure optimal performance under various working conditions. The maximum power of a single drive is close to 355 kW (450 hp), which significantly increases the output and makes the crushing operation more efficient.

Convenient maintenance, safe and worry-free

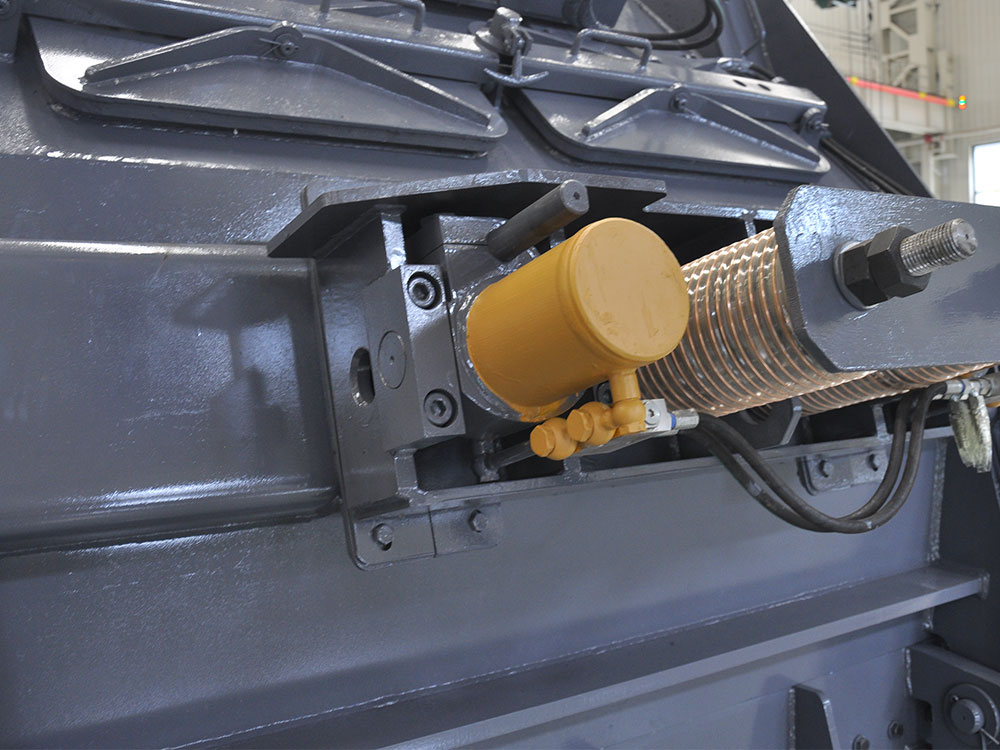

The ultra-wide opening design of the new frame makes replacement of wearing parts a breeze, greatly reducing maintenance costs and time. The removable impact plate module allows the impact plate lining to be replaced safely and conveniently from the outside, taking maintenance convenience to a new level. This design is not only the center point for adjusting the discharge port and replacing the plate hammer, but also provides strong support for safety and stable operation.

Wide range of applications, omnipotent

Whether it is the second and third crushing sections of aggregate production, waste material crushing in the recycling field, or various hardness and rock processing in mining production, the NP15 impact crusher can complete the task with ease and efficiently. It is not only a leader in the crushing industry, but also a powerful assistant in resource recycling and mining production.

NP15 impact crusher Working Principle

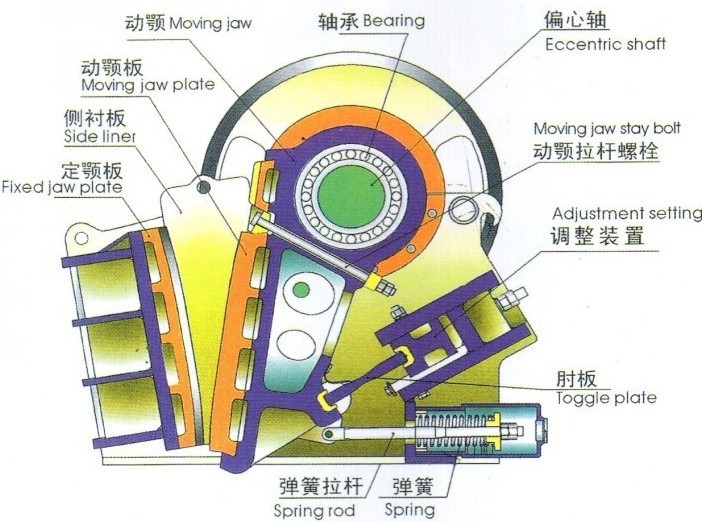

The working principle of the P15 impact crusher is quite ingenious. The working principle of the NP15 impact crusher is mainly based on the interaction between the high-speed rotating rotor and the impact plate. Specifically, when the material falls into the machine from the feed port, it will enter the rotation range of the plate hammer connected to the rotor. At this time, the material will be impacted by the plate hammer running at a high speed, and will be thrown to the impact plate of the upper support of the machine body at a high speed along the tangent direction of the plate hammer rotation, and produce a strong impact.

After the impact, the material will return from the impact plate to the plate hammer rotation area and continue to repeat the above process. In this process, the material is repeatedly impacted by the plate hammer and the impact plate, as well as the mutual impact in the crushing chamber, causing the internal structure of the material to be broken and loosened. Finally, the material that is crushed into small particles will be forced to be discharged in the gap between the plate hammer and the impact plate, becoming the crushed product.

This working principle makes the NP15 impact crusher have the advantages of high crushing efficiency, uniform product particle size, and strong adaptability, and can be widely used in aggregate production, recycling and mining production.

NP15 impact crusher Technical Parameters

| Crushing range | Secondary and tertiary | weight | 16 130 kg |

| power | 315 kW | Maximum installed power | 355 kW |

| Feed size | 1 540 x 600 mm | Maximum feed size | 400 mm |