How to choose Lokotrack ST3.8™ sand washer for ore processing

Lokotrack ST3.8™ is a mobile screening equipment specially designed for sand and ore production lines. It is widely used in sand washing, fine sand recovery, screening and other process links. Known for its flexibility and high efficiency, this equipment is suitable for a variety of harsh working environments and can achieve efficient operations in multiple industries. ST3.8™ is equipped with a multi-layer screen system that can accurately screen sand and gravel of different particle sizes and effectively clean impurities. Its unique design enables it to recover a large amount of fine sand during the sand washing process, ensuring high-quality output of materials. The dehydration function of this equipment is very powerful, which can effectively remove excess moisture from sand and gravel, improve the dryness and quality of sand and gravel, and meet the production needs of high-standard building materials. As a mobile unit, Lokotrack ST3.8™ is designed for convenience and flexibility, enabling quick deployment and relocation, making it ideal for changing work environments such as construction sites and mining sites. Its modular design allows users to customize configurations according to specific needs, further improving operating efficiency. In addition, ST3.8™ is also equipped with an advanced automated control system that can monitor equipment operating status in real time, reducing downtime and maintenance costs. To sum up, the Lokotrack ST3.8™ sand washing machine not only has efficient sand washing and screening capabilities, but also has excellent durability and flexibility. It is an indispensable ideal in the sand and gravel production, mineral processing and recycling industries equipment.

ST3.8™ sand washer advantages

Efficient screening and sand washing capabilities

The Lokotrack ST3.8™ is equipped with a multi-layer vibrating screen that can efficiently screen sand and gravel of different particle sizes. It uses a unique screening system to effectively separate larger particles from fine particles to ensure the high purity of fine sand. In addition, with the high-pressure spray water system, it can fully remove impurities on the surface of sand and gravel, such as clay and soil, to improve the quality of sand and gravel. The combination of sand washing and screening functions enables it to provide stable productivity in multiple industries.

Fine sand recovery system reduces waste

The ST3.8™ is equipped with an advanced fine sand recovery system, which efficiently separates fine sand from the mixed cement slurry through rotation and centrifugal force. This can minimize the loss of fine sand and re-invest the recovered fine sand in the production process. This innovative design not only improves production efficiency, but also greatly reduces the waste of raw materials, helping companies save costs.

High flexibility and mobility

As a mobile sand washer, the Lokotrack ST3.8™ is compact in design and sturdy in structure, and can easily cope with different working environments. The equipment is equipped with a crawler chassis, which can be quickly moved and dispatched to adapt to various construction sites, especially suitable for changing site conditions. Whether it is a mountainous mining area or a construction site, ST3.8™ can be put into use quickly, greatly improving work efficiency.

Intelligent control system

Lokotrack ST3.8™ is equipped with an intelligent control system that can monitor the equipment's operating status in real time and make optimization adjustments. The system can be adjusted through remote operation, reducing manual intervention and improving the automation level of the equipment. Through real-time data collection, the operator can monitor the screening effect, sand washing process and equipment status to avoid potential failures and downtime, reduce maintenance costs and improve equipment reliability.

Low energy consumption and environmentally friendly design

Lokotrack ST3.8™ is designed with energy saving and environmental protection in mind. The equipment's efficient screening and recovery system can significantly reduce water and energy consumption. At the same time, it is equipped with an advanced dehydration device that can effectively remove moisture from sand and gravel, avoiding the waste of water resources. The working principle and function of this equipment not only improve production efficiency, but also meet modern environmental protection requirements, reduce negative impacts on the environment, and is an ideal choice for sustainable development.

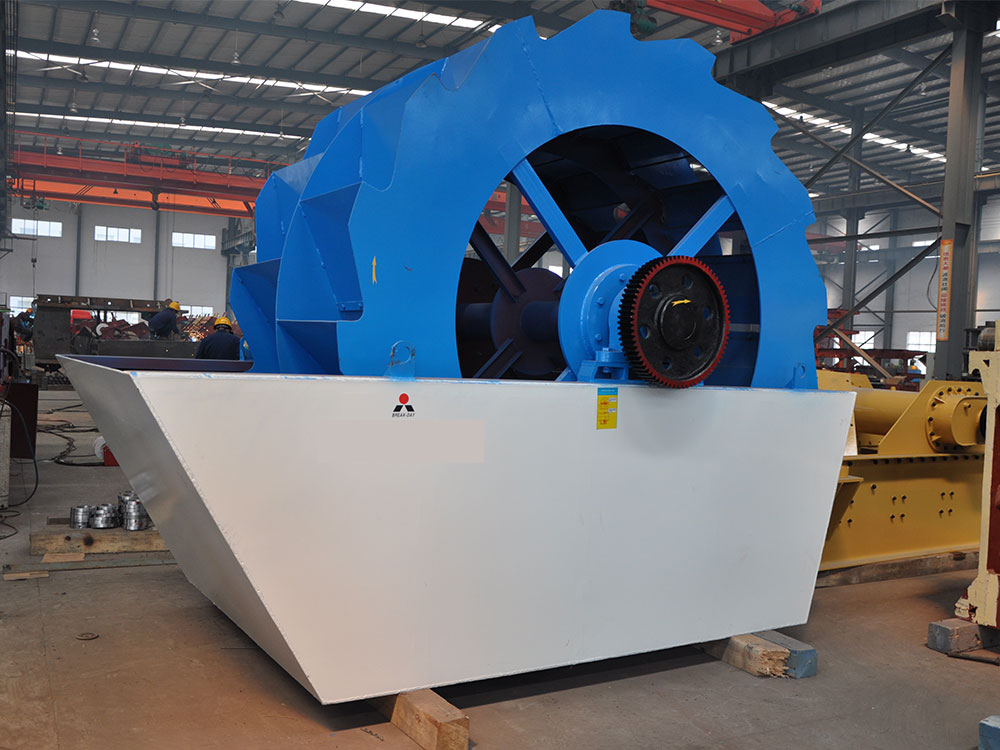

Working principle of ST3.8™ sand washer

The working principle of Lokotrack ST3.8™ sand washer is based on an efficient screening and fine sand recovery system. Its core function is to screen the sand and gravel through multiple layers of screens and effectively remove impurities in them through a water washing process to ensure high quality and high purity of the product. First, the material enters the machine through a feeder and enters the screening area, where it is initially screened by a vibrating screen. The screen separates large particles and oversized sand and gravel through high-speed vibration, while fine particles pass through the pores of the screen into the next sand washing process. During the screening process, Lokotrack ST3.8™ uses a spray water system to wash the sand and gravel, and the water flow washes away the dust and impurities adhering to the surface of the sand and gravel. During the sand washing process, fine sand and water are mixed to form a slurry, which is effectively recovered through a dedicated fine sand recovery system. This system separates the fine sand from the water through rotation and centrifugal force and re-transports it to the screening area or other aggregate system, thereby minimizing the loss of fine sand. At the same time, the multi-layer screens finely screen the materials of different particle sizes to ensure the particle uniformity of the finished sand and gravel. In addition, the design of the Lokotrack ST3.8™ sand washer makes it very suitable for mobile operations and can be flexibly transferred between multiple construction sites. Its efficient dewatering function effectively removes moisture from the sand and gravel, improving the dryness of the sand and gravel, which meets the strict requirements of the modern construction industry for sand and gravel quality. In summary, the Lokotrack ST3.8™ sand washer ensures efficient cleaning and grading of sand and gravel through processes such as vibration screening, spray water washing and fine sand recovery, and is suitable for various sand and gravel processing and sand washing needs.

ST3.8™ sand washer technical parameters

| Output | 250-400t/h | Vibration frequency | 700-800 times/min |

| Screen size | 4-20mm | Motor power | 37-55 kW |

| Vibration frequency | 700-800 times/min | Weight | 38t |

ST3.8™ sand washer case and customer testimonials

Case details

In a large-scale sand and gravel production project in Thailand, the customer faced the following challenges

High mud content sand and gravel: Due to the high proportion of mud and fine particles in the local sand and gravel resources, traditional sand washing equipment cannot effectively remove impurities, resulting in product quality that is difficult to meet market standards. High production capacity requirements: The customer needs to improve production efficiency to meet the growing market demand, especially in the context of the increasing demand for high-quality sand and gravel in the construction industry. Environmental requirements: With the strict environmental regulations, the customer needs an efficient system to recycle and treat wastewater in the production process to reduce water waste.

Efficient screening and washing

The Lokotrack ST3.8™ is equipped with an advanced multi-layer screen system that can effectively screen and wash sand and gravel materials with high mud content, remove fine particles and mud impurities, and improve the quality of sand and gravel. This is very important for the mud-containing sand and gravel treatment faced in the Thai project, ensuring that the final sand and gravel products meet construction standards. The successful application of the Lokotrack ST3.8™ sand washer in Thailand fully demonstrates its strong advantages in efficient screening, sand washing, fine sand recovery and environmental protection. Its excellent performance and flexibility have helped customers solve multiple problems in actual production, improved product quality, optimized production processes, and reduced operating costs. It is an important technical solution in Thailand's sand and gravel production industry.

Customer evaluation

"The fine sand recovery system is a highlight that we value very much. The fine sand produced during the sand washing process is almost not lost, and the recovery rate is very high. It not only improves material utilization, but also greatly reduces waste and saves a lot of raw material costs."

"The mobility of the equipment allows us to quickly mobilize between different work locations. The operation and maintenance are relatively simple, reducing downtime. This equipment not only improves our production efficiency, but also provides us with stable and long-term production guarantees."