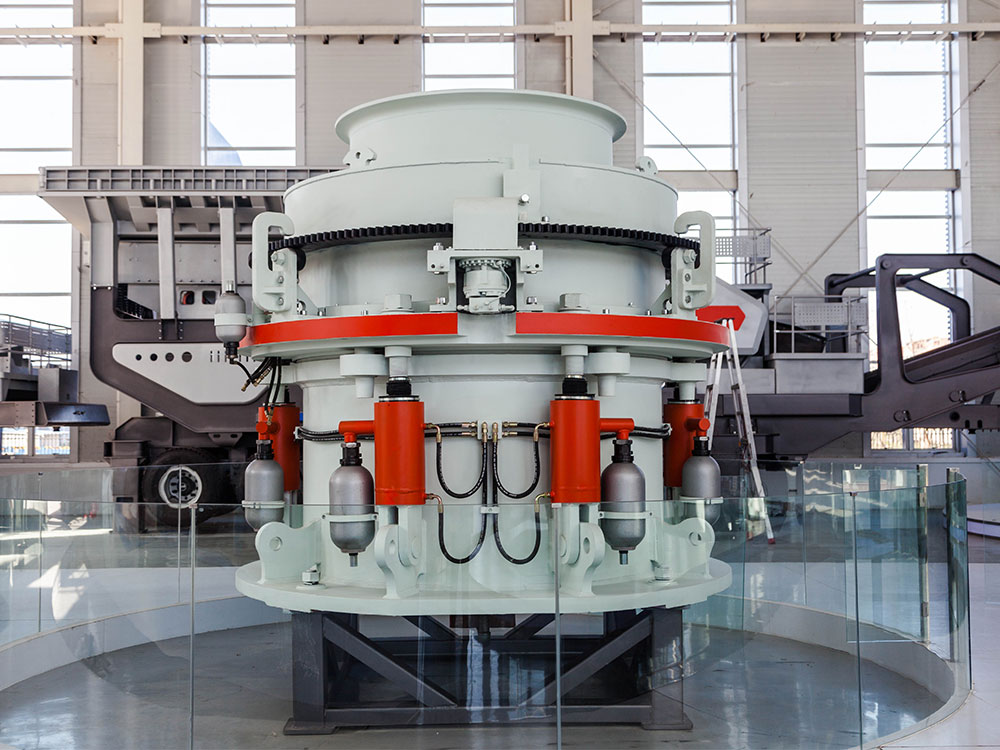

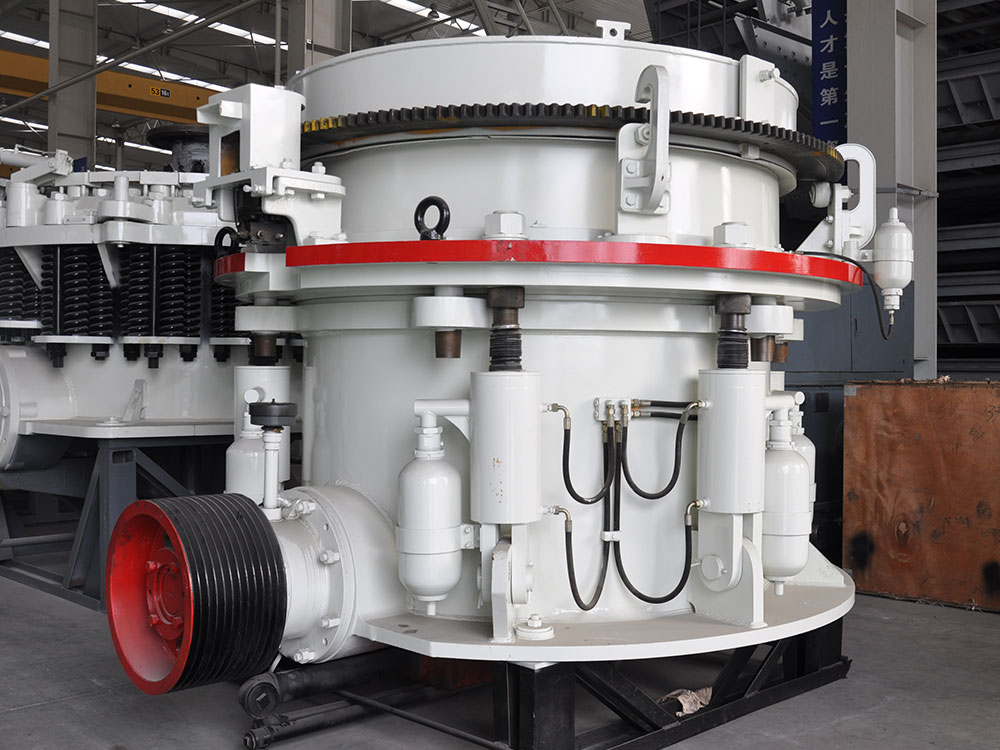

HP500 multi-cylinder cone crusher

HP500 multi-cylinder cone crusher, a device that combines precision design and high performance, has a core structure carefully assembled from a series of precision components, including a stable horizontal shaft, precision-matched large and small bevel gears, a main shaft that carries the crushing force, an eccentric sleeve that drives the eccentric movement, a stable spherical tile frame and spherical tile, a flexible moving cone assembly and a fixed cone assembly, an adjustment ring for adjusting the crushing gap, and a stable main frame. It is particularly worth mentioning that its unique hydraulic system design integrates 6 "over-iron" release hydraulic cylinders and 8 locking hydraulic cylinders, which is not only compact in structure, but also convenient for daily maintenance and maintenance.

The precise coordination and coordinated work of these components have jointly created the high efficiency and stability of the HP500 multi-cylinder cone crusher in crushing operations. Its application fields are wide, covering from ore crushing in metal mines, sand and gravel processing and sand and gravel material field processing in the construction industry, to concrete mixing plants, dry mortar production, and even environmental protection fields such as desulfurization in power plants. Whether it is hard river pebbles, granite, basalt, or common iron ore, limestone, quartz, HP500 multi-cylinder cone crusher can easily cope with it with its powerful crushing ability, becoming an ideal equipment for processing a variety of materials.

In the crushing equipment market, HP500 multi-cylinder cone crusher occupies a pivotal position with its significant advantages of high efficiency, stability and easy maintenance. With the rapid development of technology and the continuous expansion of the market, this equipment is gradually penetrating into more industries and fields, contributing important forces to improving production efficiency, reducing operating costs and promoting industry progress. In the future, HP500 multi-cylinder cone crusher will continue to lead the development trend of crushing technology and inject new vitality into the sustainable development of various industries.

HP500 multi-cylinder cone crusher Applications

In today's rapidly developing industrial and construction fields, efficient and reliable crushing equipment is the key to ensuring the efficiency and quality of raw material processing. HP500 multi-cylinder cone crusher, with its excellent crushing capacity, wide applicability and advanced technical design, stands out in many industries and has become the preferred equipment in many fields such as metal mines, construction sand and gravel processing, sand and gravel yards, concrete mixing plants, dry mortar production and power plant desulfurization.

HP500 multi-cylinder cone crusher adopts advanced crushing mechanism. Through its unique multi-cylinder hydraulic adjustment system, it can easily cope with a variety of high-hardness and high-abrasive materials including river pebbles, granite, basalt, iron ore, limestone, quartz stone, etc. Its powerful crushing force not only ensures the crushing efficiency, but also ensures the uniformity of product particle shape and good finished product quality, meeting the strict requirements of different industries for raw material particle size.

From ore crushing in metal mines, to sand and gravel processing in the construction industry, to raw material pretreatment in concrete mixing plants, HP500 multi-cylinder cone crusher has demonstrated its incomparable advantages with its wide applicability. In the gravel yard, it can efficiently crush large pieces of material to the required particle size, providing convenience for subsequent screening, cleaning and other links; in the concrete mixing station, its stable output capacity ensures the continuous supply of concrete raw materials; and in the fields of dry mortar production and power plant desulfurization, HP500 also plays an important role, helping enterprises to improve production efficiency and reduce costs.

The HP500 multi-cylinder cone crusher incorporates a number of innovative technologies in its design, such as intelligent control systems, automatic adjustment functions and efficient cooling systems, so that the equipment can achieve low energy consumption and low noise operation while maintaining high performance. The intelligent control system can monitor the operating status of the equipment in real time, adjust parameters in time, and ensure the stability and safety of the crushing process; the automatic adjustment function greatly simplifies the operation process, reduces the need for manual intervention, and improves work efficiency. In addition, the efficient cooling system effectively extends the service life of the equipment and reduces maintenance costs.

HP500 multi-cylinder cone crusher Advantages

Efficient crushing, excellent production capacity

The HP500 multi-cylinder cone crusher adopts an advanced crushing chamber design, combined with an optimized laminated crushing principle, which can achieve efficient crushing of ore materials of various hardnesses. Its unique crushing mechanism effectively improves the crushing efficiency and reduces the phenomenon of over-crushing, thereby greatly improving the overall production capacity while ensuring the excellent particle shape of the finished product. Whether it is a large mine or a small and medium-sized quarry, the HP500 can easily cope with it and meet the production needs of different scales.

Intelligent control, convenient operation

Integrating the latest intelligent control technology, the HP500 multi-cylinder cone crusher realizes remote monitoring and automatic adjustment. Through the advanced sensor system, the equipment operation status is monitored in real time, including key parameters such as load, temperature, vibration, etc., to ensure that the equipment is always in the best working condition. At the same time, the intelligent control system also supports fault warning and remote diagnosis, which greatly reduces maintenance costs and improves production continuity. For operators, the friendly human-machine interface and intuitive operation guide make operation easier and faster.

Durable and wear-resistant, low maintenance cost

The HP500 multi-cylinder cone crusher has been comprehensively upgraded in material selection and structural design. The crushing wall and mortar wall are made of high-strength wear-resistant materials, which significantly improves the service life of the components. In addition, the optimized crushing chamber design reduces the impact and wear of materials on the equipment, further extending the service life of the equipment. Low failure rate and long life mean lower maintenance costs and shorter downtime, bringing significant economic benefits to users.

Environmental protection and energy saving, green production

Today, when environmental protection is increasingly valued, the HP500 multi-cylinder cone crusher actively responds to the call for green production and achieves significant energy saving effects by optimizing the power system and energy recovery technology. Its efficient crushing efficiency reduces energy consumption. At the same time, the advanced dust collection and treatment system ensures low emissions during the production process and effectively protects the environment. Choosing HP500 means choosing a sustainable mining production path.

Flexible configuration and strong adaptability

The HP500 multi-cylinder cone crusher provides a variety of configuration options, which can be flexibly adjusted according to the actual needs of users. Whether it is adjusting the crushing size, optimizing production capacity, or adapting to the crushing requirements of different materials, HP500 can provide customized solutions. This high degree of flexibility makes HP500 an ideal choice for many mining companies to transform and upgrade and enhance their competitiveness.

HP500 multi-cylinder cone crusher Working Principle

The working principle of HP500 multi-cylinder cone crusher is mainly based on advanced laminated crushing technology. Through precise mechanical design and hydraulic control system, it realizes efficient crushing of bulk materials. When the motor is started, the powerful power is smoothly transmitted to the main shaft through the transmission device (such as coupling, reducer, etc.). The main shaft drives the eccentric sleeve to start rotating. The rotation of the eccentric sleeve is the key driving force for the subsequent crushing action. The rotation of the eccentric sleeve further drives the moving cone to perform complex rotating and swinging movements. The motion trajectory of the moving cone is a conical surface with the main shaft as the axis, which enables the moving cone to continuously approach and move away from the static cone (fixed cone) in the crushing chamber. In the section where the moving cone is close to the static cone, a gradually shrinking crushing chamber is formed between the two cones. The material is evenly fed into the crushing chamber through the feeder and is subjected to the strong extrusion and shearing action between the moving cone and the static cone. This laminated crushing method allows the material to be crushed multiple times and in multiple directions in the crushing chamber, and the particle size gradually decreases until the predetermined crushing effect is achieved. The adjustment ring is a key component for controlling the crushing fineness. By moving the adjustment ring up and down, the minimum gap between the moving cone and the static cone (i.e. the size of the discharge port) can be changed, thereby achieving precise adjustment of the crushing fineness. Users can easily adjust the position of the adjustment ring through the hydraulic system according to actual needs to obtain the required crushing product particle size. The fully crushed material gradually moves downward to the bottom of the cone under the action of its own gravity and the flow of materials in the crushing chamber. When the material particle size is smaller than the size of the discharge port, the material is discharged from the crusher smoothly. The entire discharge process is smooth and efficient, ensuring the continuous and stable operation of the equipment. The HP500 multi-cylinder cone crusher is also equipped with advanced safety and protection systems. For example, the "over-iron" release hydraulic cylinder can automatically release pressure when unbreakable objects enter the crushing chamber to avoid equipment damage; while the locking hydraulic cylinder ensures the stability and safety of the equipment during operation.

HP500 multi-cylinder cone crusher Technical Parameters

| Head diameter | 1 520 mm (60") | Power | 355 kW (500 hp) |

| Weight (complete crusher) | 37 000 kg (81 600 lbs) | Feed opening | 351 mm (13 3/4") |

| Maximum capacity | 790 Mtph (870 Stph) |