I1011 mobile impact crusher Aggregate Equipment For Sale

The I1011 mobile impact crusher cleverly combines advanced impact crushing principles with mobile design, allowing it to easily cope with various complex operating environment challenges. The equipment consists of multiple key parts such as feeding system, crushing system, transmission system and mobile chassis. The overall structure is compact and easy to operate. Its working principle is to use a high-speed rotating impact plate to violently impact the material. After the material is impacted, it will have multiple violent collisions with other materials or the impact plate, thereby achieving the crushing effect. During this process, the material will undergo multiple actions such as extrusion, rolling and bending until it is crushed to the required particle size. The I1011 mobile impact crusher exhibits efficient crushing capabilities and can quickly process materials to ideal particle size, significantly improving production efficiency. In addition, the equipment is also suitable for crushing limestone, coal, salt, chalk, quartz stone and other materials, and is especially good at processing medium-hard rocks and ores.

I1011 mobile impact crusher Applications

In the mining industry, the I1011 mobile impact crusher often takes on the important task of finely crushing ore into smaller particles, laying a solid foundation for subsequent mineral processing, smelting and other processes. Its efficient crushing capacity and wide material adaptability undoubtedly make it the core equipment in mining.

The construction field has also witnessed the extraordinary value of this equipment. Processing construction waste and waste concrete, converting them into recycled aggregates, and then producing new building materials, not only reduces the pressure of construction waste on the environment, but also realizes the effective recycling of resources, saves raw materials, and reduces production costs.

In the fields of infrastructure construction such as roads, railways, and water conservancy, the I1011 mobile impact crusher also performs well. It can accurately crush large pieces of stone to the required particle size, providing high-quality fillers for projects such as roadbed filling and dam construction. Its strong mobility allows it to quickly move to different work sites and easily cope with complex construction environments.

In addition, the equipment also shows its prowess in the chemical and metallurgical industries. It can process materials of various hardness and provide key raw materials and fillers for production. Its precise particle size control and high crushing efficiency have won praise from these industries and its position is irreplaceable.

I1011 mobile impact crusher Advantages

Efficient crushing

The I1011 mobile impact crusher has efficient crushing capacity and can quickly crush materials to the required particle size to improve production efficiency.

Strong adaptability

The equipment is suitable for crushing a variety of materials, such as limestone, coal, salt, chalk, quartz stone, etc., especially suitable for processing medium-hard rocks and ores.

Good finished product particle shape

The crushed materials are cubic particles with neat particle shape and low needle-like content, which meets the use requirements of high-quality aggregates.

Adjustable particle size

By adjusting the gap between the impact plate and the impeller, the particle size of the finished product can be flexibly controlled to meet different engineering needs.

Good mobility

The equipment is equipped with a mobile chassis, which can be quickly transferred to different work sites. It has strong adaptability and is especially suitable for engineering projects with high mobility.

Environmental protection and energy saving

Modern mobile impact crushers are usually equipped with dust removal and noise reduction equipment to reduce the impact on the environment, while the energy consumption is relatively low.

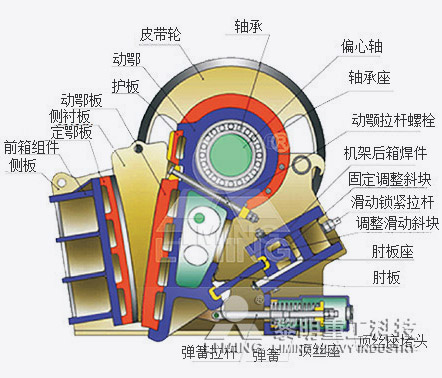

I1011 mobile impact crusher Working Principle

The working principle of the I1011 mobile impact crusher is quite exquisite. When the material enters the crusher, it will first encounter the high-speed rotating impact plate. This impact plate hits the material at a very high speed, causing the material to be subjected to a strong impact. Subsequently, the material will be rebounded into the crushing chamber and collide with the subsequent material or impact plate again. This repeated collision and extrusion will gradually crush the material into smaller particles.

Specifically, when the material enters the plate hammer action area, it will be impacted by the plate hammer at high speed and continuously thrown onto the impact device installed above the rotor. Then, the material will rebound from the impact liner back to the plate hammer action area and be hit again. This process will be repeated in the crushing chamber until the material is crushed to the required particle size and finally discharged from the lower part of the machine.

This working principle makes the I1011 mobile impact crusher have the advantages of high efficiency, energy saving, and environmental protection, and is widely used in mining, construction, roads, railways and other fields.

I1011 mobile impact crusher Technical Parameters

| width | 3 m (9’ 11”) | height | 3.3 m (10’ 11") |

| Feed port size | 1150 x 800mm (45” x 32”) | length | 15.8 m (51’ 10") |

| Feed particle size | 1000mm | Weight | 34.9 t (76 830 lbs) |