In-depth understanding of HP900 cone crusher structure design

HP900 Cone Crusher is widely used in all kinds of crushing lines due to its powerful crushing capacity and stable performance. With its compact structure and reasonable design, it can flexibly adapt to various working environments and provide users with efficient and reliable crushing solutions. The foundation of the machine is installed with steel base and vibration damping block, which effectively reduces the dynamic load by 70%. The drive system and control system are assembled at the factory, which reduces the installation time by 50%. In addition, the HP900 comes standard with the IC70C automatic control system, which allows for increased productivity through remote automation technology. This cone crusher is mainly used for medium and fine crushing of high hardness materials. In the mining industry, it can handle ores of various hardnesses and produce finished products of the required size; in the aggregate industry, it can crush various rocks and minerals and provide high-quality aggregates for the fields of construction and roads.

In-depth understanding of HP900 cone crusher structure design Applications

In the mining industry, HP900 cone crusher can handle various hardness of ores, such as river pebbles, sandstone, coal gangue, etc., crushing them into the required particle size, providing high-quality raw materials for subsequent smelting and processing.

In the aggregate industry, HP900 cone crusher can crush all kinds of rocks and minerals to produce high-quality aggregates, which are used in construction, roads, bridges and other fields. These aggregates are characterised by uniform particle size, high strength and good durability, and can meet the needs of various projects.

In metallurgical industry, HP900 cone crusher also plays an important role. It is capable of crushing various metal ores to provide necessary raw materials for the smelting process. At the same time, due to its high crushing efficiency, low energy consumption and other characteristics, it can also reduce production costs and improve economic efficiency.

In the chemical industry, HP900 Cone Crusher is capable of crushing various chemical raw materials, such as quartz sand, etc., to provide uniform particle size distribution for the chemical reaction, thus improving the reaction efficiency and product quality.

In addition, HP900 cone crusher is also widely used in building materials industry, transport facilities and other fields, providing high-quality crushing equipment and solutions for the construction of various engineering projects.

In-depth understanding of HP900 cone crusher structure design Advantages

High degree of intelligence

HP900 crusher is equipped with advanced intelligent control system, which can monitor the running status and production data of the equipment in real time. This feature makes it easier for the operator to grasp the working condition of the equipment and adjust the production parameters in time to ensure the stable operation of the equipment. At the same time, the intelligent system can also automatically stop the machine in case of emergency to ensure production safety.

Small footprint and easy installation

HP900 crusher adopts compact design, which makes the equipment cover a smaller area. This feature enables the HP900 crusher to adapt more flexibly to various working environments, especially in aggregate production sites with limited space. In addition, the HP900 crusher's drive system is pre-assembled, eliminating the need for on-site construction, and is pre-wired to an integrated automated control system, which greatly simplifies the installation and commissioning process.

Easy maintenance and reduced operating costs

The main components of the HP900 crusher can be serviced from the top, including the dynamic cone, main shaft and eccentric shaft. This design makes it easier for maintenance personnel to carry out equipment maintenance and repair work, reducing maintenance costs. At the same time, the HP900 crusher's wear parts can be replaced faster than similar cone crushers, further reducing downtime and maintenance costs.

High Quality Finished Product Size

The HP900 crusher adopts fixed-shaft structure design and combines with laminar crushing cavity design, which makes the finished product size uniform and cubic. This high-quality particle size distribution not only meets the strict requirements of the aggregate industry for finished product size, but also improves the added value of the product.

High-efficiency crushing capacity

The HP900 crusher adopts a new dynamic design and a higher dynamic cone suspension point, resulting in a significantly higher stroke than its predecessor, which achieves a 15% increase in capacity and a 25% increase in crushing force. This enhancement allows the HP900 crusher to be more efficient and productive when processing aggregates.

In-depth understanding of HP900 cone crusher structure design Working Principle

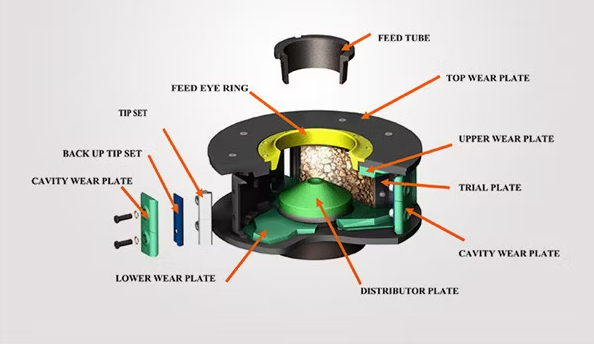

HP900 Cone Crusher is mainly driven by the drive shaft on the main frame. The pulley drives the drive shaft to rotate, which in turn drives the eccentric sleeve to rotate, enabling the moving cone to rotate around the spherical tile. The material is fed into the crushing chamber through the feeder, and is gradually crushed into fine particles through repeated extrusion and impact between the moving cone and the fixed cone. Eventually, the fines are discharged through the hopper.

In the crushing process, the adjusting ring plays a key role, by adjusting it can flexibly change the distance between the moving cone and the fixed cone, so as to accurately control the crushing fineness of the material to meet different production requirements. In addition, the HP900 Cone Crusher is equipped with advanced hydraulic and electric control systems, which realise the interlocking functions between the locking cylinder and the hydraulic motor, the clearing cylinder, the main machine and the lubrication pump, as well as the feeding device and the main machine. These interlocking functions ensure the stable operation of the equipment and greatly improve its reliability and safety.

In-depth understanding of HP900 cone crusher structure design Technical Parameters

| Output | 500-800t/h | Minimum setting | 9 mm |

| Feed size | 356 mm | power | 700 kW |

| Wear parts | 8 profiles | Weight | 77,960 kg |