Innovative Design and Superior Performance of HP350e Cone Crusher

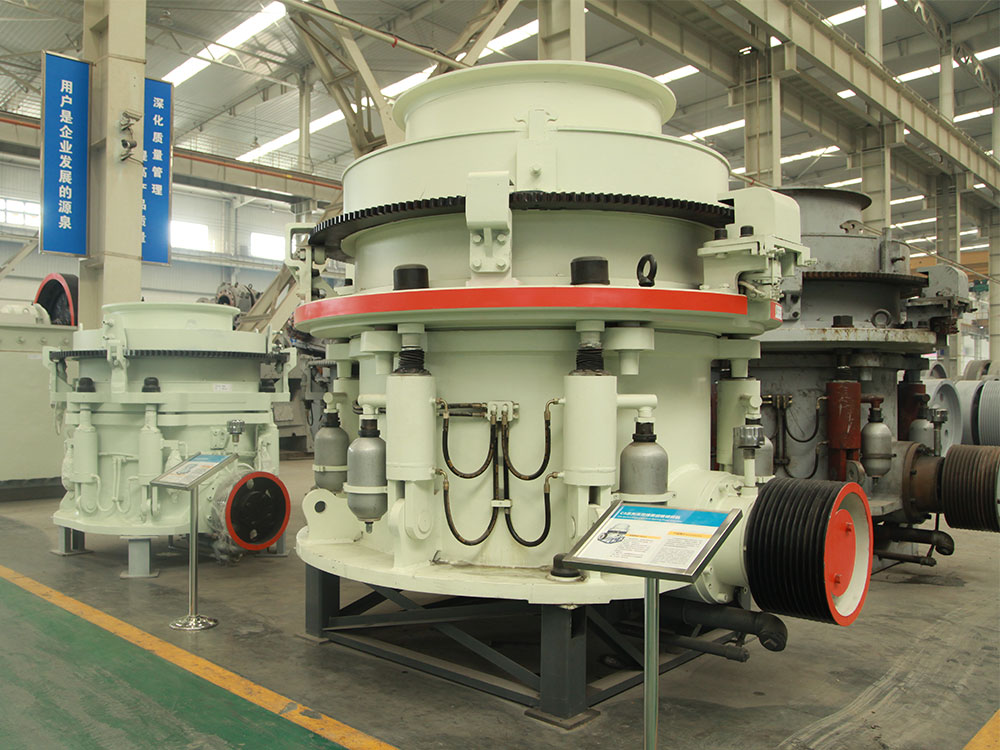

The HPe crusher range has been designed to meet the continuously growing demand for crusher performance in the aggregates and mining industries. Since its launch, the series has won wide acclaim in the market for its outstanding performance and wide range of applications.

The HP350e Cone Crusher, as the latest addition to the HPe series, not only inherits all the advantages of the series, but also achieves significant performance improvements. Its new dynamic design allows the performance of medium and fine crushing applications to jump by more than 10%, which not only improves crushing efficiency but also reduces energy consumption. The uptime of the HP350e has been significantly extended through structural and design optimisations, ensuring that users are able to produce for longer and thus increase overall efficiency.

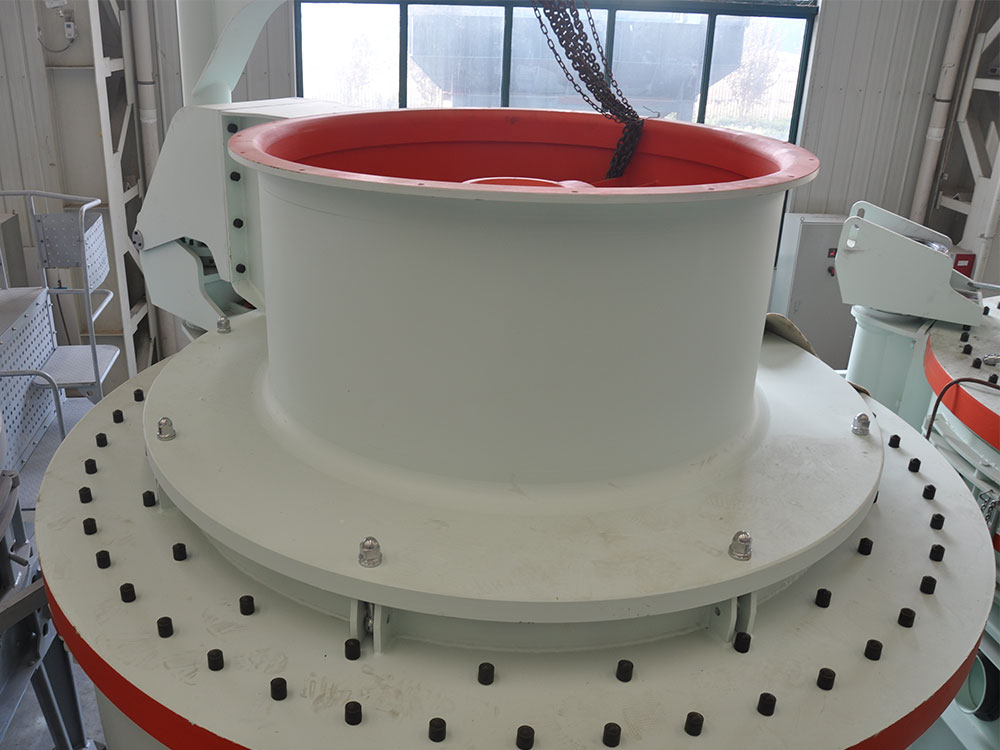

The HP350e also excels when it comes to maintenance. Packing-free liner installation makes replacement quick, easy and safe. The self-propelled cone design extends liner life. And the optional rack ring bounce monitoring function realises active overload protection.

The HP350e offers two types of strokes and 10 liner cavity shapes to meet a wide range of material crushing needs. Whether in metal mines, coal mines, cement plants or construction material plants, the HP350e can show excellent crushing results.

In addition, HP350e cone crusher adopts advanced design concepts and technical means to ensure the stability and durability of the equipment. It has a compact structure, reasonable layout, and smooth and reliable operation. The design, moreover, gives full consideration to the safety and comfort of the operators and is equipped with perfect safety protection devices to effectively prevent accidental injuries.

Innovative Design and Superior Performance of HP350e Cone Crusher Applications

The HP350e cone crusher is able to cope with ores of various hardnesses, including iron ore, gold ore, copper ore, etc. It easily meets the demand for high-performance crushing equipment in the mining industry. With excellent crushing capacity and stable operation performance, it helps mining enterprises to mine and process ores more efficiently.

In the aggregate industry, the HP350e Cone Crusher also performs well, crushing all kinds of rocks and gravels to produce standardised aggregates. These aggregates are widely used in the construction of buildings, roads, bridges and other infrastructures, contributing to the sustainable development of the society. In addition, it can also process raw materials such as river pebbles, granite, basalt, etc., providing solid support for the production of high-quality building materials.

Metallurgical and chemical industries are also inseparable from HP350e cone crusher. It is capable of crushing all kinds of metallurgical and chemical raw materials, providing ideal particle size and shape for subsequent smelting, processing and chemical reaction.

Not only that, the HP350e cone crusher is also widely used in other industries that require crushing and processing, such as cement plants. Its wide range of application and excellent performance make it the preferred equipment for many enterprises.

Innovative Design and Superior Performance of HP350e Cone Crusher Advantages

Component versatility

One of the highlights of the HP350e cone crusher is the versatility of its components. Most of the components are common between the earlier HP300 and HP350e models, and the rest can be used interchangeably or upgraded. HP300 users can economically enjoy the new features of the HPe crusher, such as enhanced dynamics, anti-rotation of the dynamic cone, and ring runout monitoring, by purchasing Metso's HPe Upgrade Toolkit. This versatility reduces upgrade costs and improves the ease of upgrading the equipment.

Wide range of applications

The HP350e Cone Crusher has a wide range of applications, offering two strokes and up to ten liner cavity shapes to meet the needs of all types of materials. Whether in metal mines, coal mines, cement factories or construction material factories, the HP350e is able to show excellent crushing results and meet the diversified needs of users.

Easy Maintenance

The HP350e Cone Crusher has undergone a number of improvements in terms of maintenance. Packing-free liner installation makes replacement quick, easy and safe. The self-propelled cone design extends liner service life, and the optional frame ring-jump monitoring provides active overload protection. These designs reduce maintenance costs and time, and improve the price/performance ratio of the machine.

Stable operation

The HP350e cone crusher is designed for stable operation, with a compact structure and rational layout to ensure smooth and reliable operation. Metso provides full-coverage after-sales service support, covering installation and commissioning, maintenance, troubleshooting and other aspects, providing professional technical support and service guarantee to ensure stable operation of the equipment.

Excellent performance

Excellent performance is another advantage of the HP350e cone crusher. With the new dynamic design, the performance of medium and fine crushing applications can be increased by more than 10%, which not only improves crushing efficiency, but also reduces energy consumption, and brings higher production benefits to users.

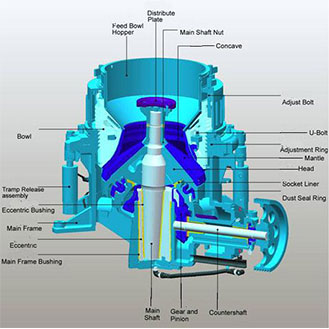

Innovative Design and Superior Performance of HP350e Cone Crusher Working Principle

When working, the motor drives the eccentric shaft to rotate through the belt pulley and transmission shaft, and drives the moving cone (movable cone) to carry out the yawing movement along the inner surface of the fixed cone (fixed cone). The moving cone is sometimes close to the fixed cone, and sometimes away from it, during the process, the material is crushed under the squeezing, bending and grinding effect of the moving cone when it is close to the fixed cone; and when the moving cone is far away from the fixed cone, the crushed material is discharged smoothly from the discharge port at the bottom of the cone under the influence of gravity. This process is continuous, the material is squeezed and crushed many times between the moving cone and the fixed cone until it reaches the required size and is finally discharged from the discharge port, and the whole crushing process is completed. With this working principle, the HP350e Cone Crusher is able to efficiently and continuously crush all kinds of hard materials, and is widely used in a variety of crushing operations.

Innovative Design and Superior Performance of HP350e Cone Crusher Technical Parameters

| power | 250 kW | weights | 16,000 kg |

| Head diameter | 1120 mm | Stroke options | 93 mm |

| Number of chambers | 10 | Capacity | 485 t/h |