J90 Mobile crushers are track-mounted rock crushing machines

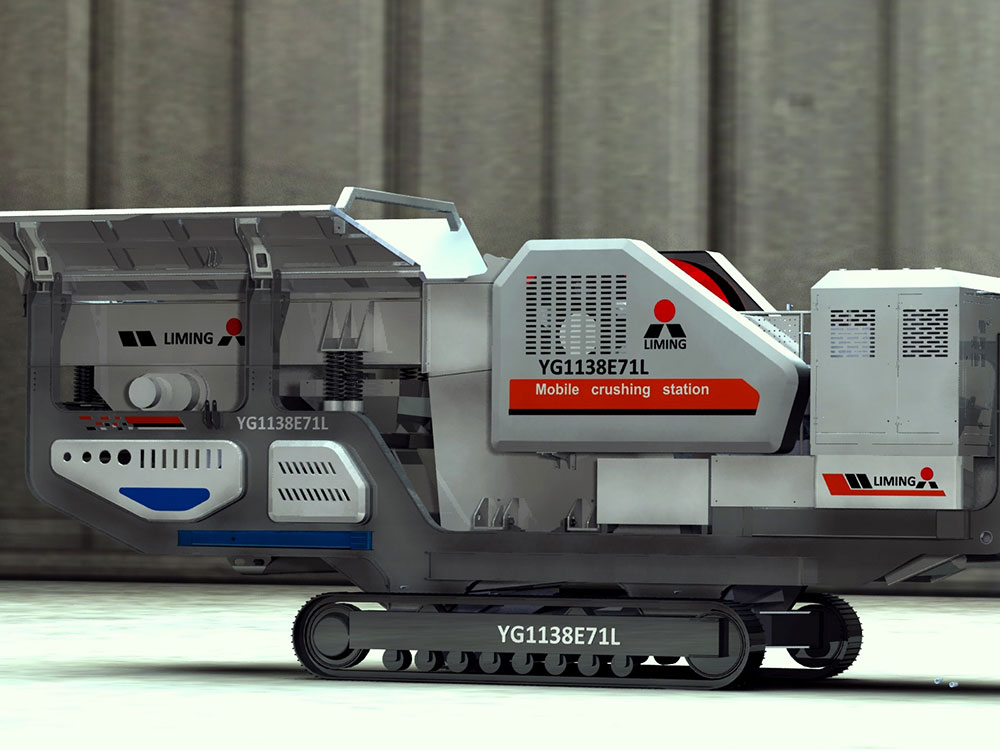

Crawler mobile crushing station, also known as crawler crusher, is a kind of crushing equipment that combines high efficiency and versatility. It is widely used in multiple fields such as mining, coal processing, cement manufacturing and construction waste treatment. The equipment is equipped with an advanced self-propelled drive system, with excellent technology and complete functions. It can easily realize the rapid change of working position, show excellent maneuverability, and adapt to various complex working environments. With the advantages of high efficiency, versatility, flexible mobility, energy saving and environmental protection, crawler crusher has become the preferred equipment in the fields of mining crushing operations, sand and gravel aggregate production, and solid waste resource utilization. With the vigorous development of information technology, crawler crushers are gradually moving towards digitalization, parallel processing, high integration and intelligence, bringing unlimited development potential to the crushing machinery industry.

track-mounted rock crushing machines Applications

In the mining sites of mines and coal mines, crawler crushers demonstrate their powerful crushing capabilities in the face of hard and complex rocks and coal seams. Its sturdy structural design and efficient crushing mechanism enable it to easily cope with materials of various hardnesses and achieve high efficiency and stability in coarse crushing operations. This not only greatly improves the mining efficiency of ore and coal, but also effectively reduces the labor intensity of workers, providing a strong guarantee for the safe production of mines and coal mines.

With the acceleration of urbanization, the treatment of construction waste has become an urgent problem to be solved. The application of crawler crushers in the field of construction waste treatment provides an effective way to solve this problem. It can crush and screen construction waste and then convert it into reusable aggregates for site operations such as earthwork projects, urban infrastructure, roads or new construction sites. This not only reduces the pollution of construction waste to the environment, but also realizes the recycling of resources and promotes the development of green buildings.

In the cement industry, crawler crushers also play an important role. It is widely used to treat a variety of materials such as topsoil, limestone, clay, and to separate viscous concrete aggregates. Through precise crushing and screening, crawler crushers provide high-quality raw materials for cement production, ensuring the quality and stability of cement products. At the same time, its efficient operation also improves the efficiency of cement production and reduces production costs.

In addition to the above fields, crawler crushers are also widely used in stripping crushing of cement concrete road reconstruction, crushing before asphalt concrete recycling, and quarrying industry. In cement concrete road reconstruction, it can quickly and accurately strip the old road surface to provide a flat foundation for the laying of new roads. In the crushing before asphalt concrete recycling, it can crush and screen waste asphalt mixtures to achieve recycling and reduce the demand for new materials. In the quarrying industry, crawler crushers have become indispensable equipment in quarries with their powerful crushing capacity and flexible mobility.

track-mounted rock crushing machines Advantages

Efficient crushing and multifunctional operation

The crawler crusher integrates the process equipment such as receiving, crushing and conveying. Through the optimization of the process flow, it has excellent crushing performance for rock crushing, aggregate production and open-pit mining. It can match different equipment according to different needs, such as jaw crusher, cone crusher, impact crusher, sand making machine and screening equipment, etc., to form a powerful crushing operation line to complete multi-demand processingoperations.

Flexible mobility and strong adaptability

The crawler crusher adopts crawler walking mode, without the various preliminary preparations required before the installation of the fixed crushing station, and can complete the station adjustment in a short time and enter the working state at any time. It is particularly suitable for working in narrow places, with light weight, small size, convenient transportation and no damage to the road surface. Through wireless remote control, the crusher can be easily driven onto the trailer and transported to the work site.

Energy saving, environmental protection and efficient utilization

The crawler crusher adopts an oil-electric dual-purpose power system, with a fuel saving rate of up to 25%. The motor power system is powerful, low noise, energy saving and environmental protection. Its optimized design enables high productivity, uniform particle size of finished materials, large crushing ratio, and meets the most required technical features of the crusher.

Intelligent Control and Remote Operation

The crawler crusher is equipped with intelligent wireless remote control operation, one-button start and stop, reducing the number of equipment operators. It can be intelligently adjusted according to different working conditions, controlling the time and direction of the feeding system, the rise/descent of the crushing chamber, and the start/stop of the diesel engine. In addition, it is also equipped with the best noise absorption system and effective dust removal system to ensure that the equipment is compact and flexible, meeting the needs of inter-city construction waste crushing operations.

track-mounted rock crushing machines Principle

The vibrating feeder is responsible for feeding the bulky raw materials into the crusher evenly. Inside the crusher, the hammer rotates at high speed on the crushing head, effectively beating the rocks or construction waste into small pieces. These crushed materials are then screened by the screen, and the large particles are intercepted by the screen, while the small particles pass smoothly. If the material does not meet the requirements, it will enter the crusher for processing again. Through the action of the vibrating screen, a closed-loop crushing system is formed to ensure that the material can be crushed repeatedly until it meets the standards. Finally, the qualified materials are sent out through the conveyor, maintaining the continuity of the crushing operation.

track-mounted rock crushing machines Principle Parameters

| Transport length | 9,300 mm (30’-”) | Weight | 23,900 kg (52,600 lbs) |

| Feed opening | 890 x 500 mm (35” x 20”) | Transport width | 2,500 mm (8’ 2”) |

| Engine | Tier 3: Volvo D5 162 kW (218 hp) / Tier 4F: Volvo D5 162 kW (218 hp) | Transport height | 3,000 mm (10’) |