LT400J jaw crusher of EC series

The new oil-electric hybrid equipment launched in the EC series has injected new vitality into the aggregate market. The equipment fully adopts electric process functions, which significantly reduces the consumption of hydraulic oil during crushing operations. LT400J is a mobile crusher specially designed for primary crushing of hard rock and recycled aggregates. It has won the favor of the market with its excellent crushing capacity and wide adaptability. Its core component, the Nordborg C120 jaw crusher, provides the LT400J with efficient and stable crushing performance. In addition, LT400J can also be used with equipment such as LT350C to meet higher-level crushing needs.

LT400J jaw crusher of EC series Applications

The LT400J jaw crusher has shown wide application potential in many fields with its excellent crushing performance. In mining, it can effectively crush various types of high-hardness ores, helping the mineral crushing and beneficiation process. The construction industry uses its crushing ability for building materials such as stone and bricks to reuse construction waste and reduce waste generation. In addition, in the field of road and bridge construction, the LT400J can handle construction waste and road materials and crush them into small particles suitable for reuse. Water conservancy projects are also inseparable from the LT400J, which provides sand and gravel aggregates for supporting projects and main construction. The metallurgical, highway, railway, chemical, cement, refractory and ceramic industries also widely use LT400J for material crushing. It is worth mentioning that the LT400J model is also suitable for coal processing, glass and ceramic processing, chemical research, food and pharmaceutical industries, and environmental monitoring and other fields. Its powerful crushing ability and wide adaptability make it a key equipment in crushing operations.

LT400J jaw crusher of EC series Advantages

High quality and high reliability

With advanced manufacturing technology and selected materials, the equipment adopts a modular, welding-free structure, showing excellent fatigue resistance, and the excellent casting process design ensures the high quality of parts.

Excellent performance

The crushing chamber is exquisitely designed, combining a large stroke, ideal speed and high installed power, while the small discharge port design makes the crushing effect better. In order to meet different application requirements, the equipment is equipped with a variety of jaws and cheeks.

Low use and installation costs

In terms of installation, the equipment is designed to be safe and fast, equipped with an easy-to-adjust setting system, and the integrated motor frame and compact flywheel guard make maintenance easier. In addition, the customized feed trough and automatic grease lubrication system further enhance the convenience and reliability of the equipment.

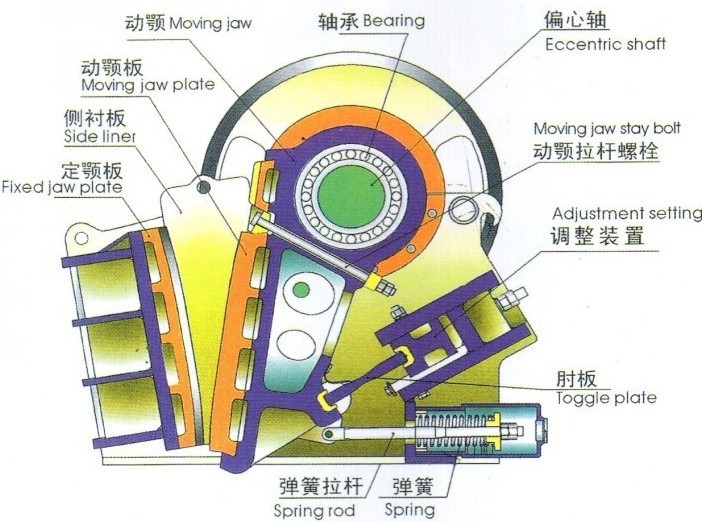

LT400J jaw crusher of EC series Principle

The crusher adopts a flexural extrusion type crushing method. The motor drives the belt and pulley, which in turn drives the eccentric shaft to make the movable jaw swing forward and backward and up and down. When the movable jaw pushes the movable jaw plate to approach the fixed jaw plate, the material is strongly crushed or split. Subsequently, under the joint action of the eccentric shaft and the spring, the movable jaw and the movable jaw plate retreat, and the crushed or split material is smoothly discharged from the lower discharge port of the jaw plate. As the motor continues to rotate, the movable jaw periodically completes the crushing and discharging actions, thereby realizing continuous and efficient batch production.

LT400J jaw crusher of EC series Parameters

| Transportation profile width | 3 000 mm (9’ 10”) | Transportation profile height | 3 400 mm (11’ 2”) |

| Transportation Outline Weight | 32 000 kg (70 500 lbs) | feed inlet | 2 700 mm (8’ 9”) |

| Feed hopper volume | 5 m³ (6.6 yd³) | Loading width | 2 440 mm (8’) |

| power (output) | 310 kW (415 hp) | Fuel tank capacity | 630 l (166 gal) |