NW200HPS portable cone crusher is suitable for secondary or tertiary crushing stations

The NW200HPS portable cone crusher is a high-performance cone crushing equipment that incorporates advanced HPS series multi-cylinder hydraulic technology. This crusher not only has powerful crushing performance, but also has flexibility and portability, perfectly adapting to the needs of mobile crushing operations on various sites. Its unique crushing chamber design and optimized crushing dynamics parameters greatly improve the crushing efficiency while reducing wear, further enhancing the overall efficiency of the production line. The NW200HPS has excellent crushing capacity and powerful processing capacity. The hourly output is between 72 and 250 tons. If calculated based on 10 hours of daily production time, the daily output can be as high as 720 to 2500 tons. The specific output depends on the raw material size and discharge particle size. Conditions are adjusted. With its efficient crushing performance, high-quality finished products, simple operating procedures, high reliability and green and environmentally friendly features, this equipment has been widely used in mining, building materials, metallurgical industry, road construction and other fields. application. NW200HPS not only significantly improves crushing efficiency and reduces energy consumption, but also provides users with a convenient and reliable experience. It performs well in terms of mobility, high crushing efficiency and modular design.

NW200HPS portable cone crusher Applications

In the mining field, NW200HPS portable cone crusher is widely used in the secondary and tertiary crushing of metal mines. Its powerful crushing capacity and high output enable it to efficiently process various medium-hard materials, such as granite, basalt, iron ore, etc. After crushing, these materials can meet the requirements of ore products with different particle sizes, providing high-quality raw materials for subsequent smelting or processing.

The building materials processing industry is also one of the important application areas of NW200HPS portable cone crusher. In the processing of building sand and gravel, the equipment can provide stable and efficient crushing performance to ensure that the particle size of building sand and gravel is uniform and the quality is reliable. In addition, NW200HPS also has the environmental protection characteristics of low noise, low vibration and no dust, which meets the requirements of green building and sustainable development.

The chemical industry also needs high-quality crushing equipment to process various raw materials. NW200HPS portable cone crusher can provide high-quality crushing products for the chemical industry through its precise crushing control and high crushing efficiency. These products can be used as raw materials or auxiliary materials for chemical production, providing strong guarantees for the quality and stability of chemical products.

In road and bridge construction, the NW200HPS portable cone crusher also plays an important role. It can be used to process aggregates and gravel required for various road constructions, ensuring the quality and stability of road construction materials. In addition, the equipment also has intelligent operation functions such as rapid adjustment of the discharge port and rapid cavity cleaning, which can greatly improve construction efficiency and reduce maintenance costs.

NW200HPS portable cone crusher Advantages

Efficient crushing, strong processing capacity

The NW200HPS cone crusher adopts advanced crushing chamber design and optimized crushing dynamic parameters, which significantly improves the crushing efficiency. The equipment's hourly output is between 72-250 tons per hour, which means that within a 10-hour production time a day, its daily output can reach 720-2500 tons. Of course, the specific output needs to be adjusted appropriately based on factors such as the size of the raw materials and discharge particle size requirements. But in any case, the high processing capacity of the NW200HPS cone crusher is enough to meet the production needs of most mining and building materials companies.

High-quality crushed products with uniform particle size distribution

In addition to efficient crushing, the NW200HPS cone crusher can also provide high-quality crushed products. By precisely controlling the size of the feed inlet and the shape of the crushing chamber, this equipment can ensure that the crushed particles have a high degree of uniformity and a small particle size distribution range. This feature enables the NW200HPS cone crusher to meet users' high requirements for finished product particle shapes, and provide high-quality products that meet standards whether used in building materials, metallurgical raw materials or other fields.

Easy to operate and highly intelligent

In terms of operation, the NW200HPS cone crusher also performs well. The equipment adopts advanced hydraulic technology and automatic control system, making the operation simple and convenient. The one-touch start/stop function not only improves operating efficiency, but also reduces operating difficulty. In addition, the NW200HPS cone crusher also supports remote control. Users can monitor the operating status of the equipment in a safe and comfortable environment, and adjust production parameters in a timely manner to ensure the stability and continuity of production.

High reliability and easy maintenance

High reliability is another highlight of the NW200HPS cone crusher. The equipment is manufactured with high-quality cast steel components and premium materials, resulting in an extremely low failure rate. At the same time, its structural design is reasonable and easy to maintain and maintain. This greatly reduces the company's downtime and maintenance costs, and improves overall production efficiency. Metso's proven quality provides a strong guarantee for the reliability and durability of the NW200HPS cone crusher.

Green and environmentally friendly, reduce environmental impact

In today's society, green environmental protection has become the focus of attention in all walks of life. The NW200HPS cone crusher fully considers environmental protection requirements during the design and manufacturing process. The equipment has the characteristics of low noise, low vibration and no dust, which not only improves the working environment, but also reduces the impact on the environment. This is in line with the sustainable development concept of modern enterprises and is one of the reasons why the NW200HPS cone crusher is so popular in the market.

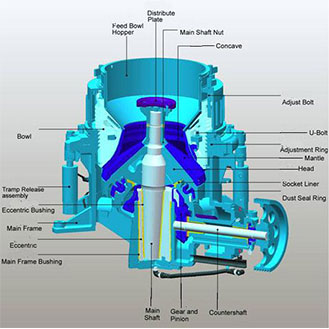

NW200HPS portable cone crusher Principle

The rotational force of the motor is transmitted to the transmission shaft of the cone crusher through a pulley or coupling, and the shaft then drives the cone to rotate and swing around a fixed point. This swinging action causes the crushing wall of the crushing cone to approach and move away from the surface of the mortar wall fixed on the adjustment sleeve. The ore is thus continuously impacted, squeezed and bent in the crushing chamber, thereby being crushed. After the crushing, the ore naturally falls to the bottom of the cone due to gravity. When foreign objects that cannot be crushed accidentally enter the crusher or the machine is overloaded, the spring safety system will compress and deform to discharge the foreign objects, thereby protecting the machine from damage.

NW200HPS portable cone crusher Principle Parameters

| Bogie weight | 22,348 kg (49,269 lbs) | Motor power | 132 kW (200 hp) |

| Weight per axle | 11,174 kg (24,635 lbs) | Decks | 4 |

| King pin weight | 13,574 kg (29,926 lbs) | Screen length | 5 500 mm |

| Feed opening | 185 mm (7") | Screen width | 1 800 mm |