NW8HRC NW Rapid Mobile Cone Crusher

The W8HRC NW Rapid Mobile Cone Crusher is a versatile crushing machine that is widely used in mining, construction and waste recycling. With its powerful crushing capacity, the machine can easily transform waste piles and various by-products into marketable finished products, which can be further used as raw materials for concrete and asphalt, promoting the effective recycling and reuse of resources.

The W8HRC NW Rapid can not only be used as a standalone crushing unit, but also flexibly integrated into complex crushing processes, becoming an indispensable part of them. Its design allows the equipment to be easily moved and redeployed between different crushing sites, thus meeting diverse operational needs.

In order to improve the transportation efficiency of the equipment, the W8HRC NW Rapid is equipped with an innovative 2-axle detachable steering axle wheeled chassis, which ensures that the equipment can meet standard size requirements during transportation, greatly simplifying the transportation process.

In addition, the equipment is also equipped with an advanced remote control system, allowing operators to adjust and optimize the process in real time without stopping the machine. This intelligent management method not only improves production efficiency, but also effectively reduces production losses caused by downtime for maintenance, further ensuring the stable operation and efficient output of equipment.

NW8HRC NW Rapid Mobile Cone Crusher Applications

In the aggregate industry, the NW8HRC NW Rapid Mobile Cone Crusher performs well. Aggregates are an important component in construction, roads and other infrastructure projects. This crusher can crush various rocks and ores into the required particle size to meet the high standards and strict requirements of aggregate production. Its efficient crushing capacity and stable product quality enable aggregate producers to produce high-quality aggregates more efficiently to meet market demand.

In the mining industry, the NW8HRC NW Rapid Mobile Cone Crusher also plays an important role. Mining operations usually need to be carried out in complex environments, requiring equipment with strong crushing capacity and good adaptability. This crusher can easily handle ores of various hardnesses and crush them into particle sizes suitable for further processing. At the same time, its convenient mobility and intelligent control system make mining operations more efficient and safe.

In the construction industry, the NW8HRC NW Rapid Mobile Cone Crusher also has a wide range of applications. The construction industry requires a large amount of building materials, such as concrete, asphalt, etc. These materials usually require machine-made sand as raw materials. NW8HRC NW Rapid Mobile Cone Crusher is able to re-crush waste and by-products into valuable machine-made sand, which can be used as raw materials for concrete and asphalt. This not only reduces waste accumulation and environmental pollution, but also improves the utilization rate of resources.

NW8HRC NW Rapid Mobile Cone Crusher Advantages

Mobility

The mobility of the NW8HRC NW Rapid Mobile Cone Crusher is a highlight. The equipment can go directly into the work site, which is suitable for driving on ordinary roads and is easy to move in rugged and harsh road environments. This high degree of mobility enables the equipment to quickly reach various complex work sites, greatly improving work efficiency.

Compact design and space saving

In terms of structure, the NW8HRC NW Rapid Mobile Cone Crusher adopts a compact design, which greatly saves floor space. The integrated vehicle-mounted complete set of equipment is not only convenient for field operations, but also comes with a vehicle-mounted generator set, motor and control box, making on-site stationing more convenient and quick. In addition, the equipment is also equipped with an advanced 2-axle detachable steering axle wheeled chassis, which is a standard transportation size and complies with EU road regulations, so it can be transported in many countries without a special transportation license.

Reduce production and transportation costs

Cost saving is another major advantage of the NW8HRC NW Rapid Mobile Cone Crusher. The mobile crushing station can crush the material on site, avoiding the turnover link of the material, thereby greatly reducing the transportation cost of the material. At the same time, the equipment also adopts an electric configuration, which has lower operating costs and is easier to maintain than diesel-driven equipment. In addition, when the external power grid is unavailable, it is less demanding to repair a large diesel generator on site than to repair diesel engines on multiple devices, further reducing maintenance costs.

Strong applicability

In terms of applicability, the NW8HRC NW Rapid Mobile Cone Crusher also demonstrates its strong strength. The equipment can not only be used as a stand-alone machine, but also as a section of the crushing process, and can be regularly moved between crushing sites. In addition, it can be combined into a coarse crushing and fine crushing two-stage crushing and screening system, or combined into a crushing-first-then-screening or screening-first-then-crushing system according to site needs. This high degree of flexibility enables the equipment to be applied to a variety of complex crushing and screening needs.

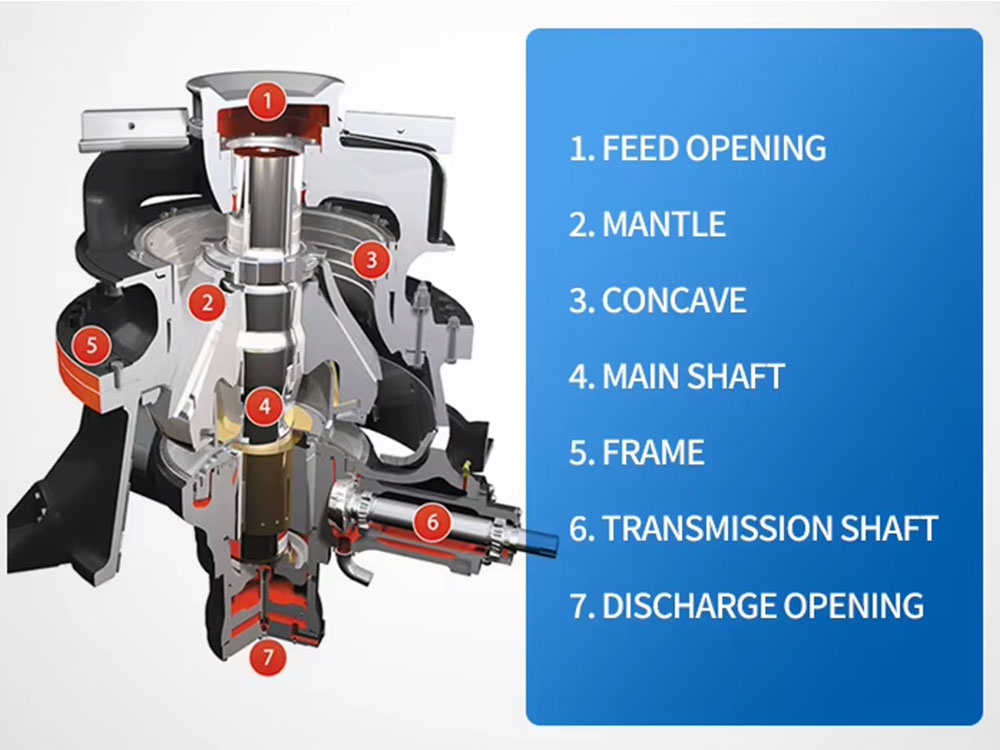

NW8HRC NW Rapid Mobile Cone Crusher Principle

The raw materials are first fed into the crushing chamber through the feed port, where they are crushed by a high-pressure roller mill or a cone crusher. Cone crushers usually rely on a motor to drive the drive shaft, which in turn drives the moving cone assembly to rotate and swing. This process involves crushing actions such as squeezing, impacting and shearing the material. The HRC 8™ high-pressure roller mill uses two relatively rotating high-pressure rollers to efficiently extrude the material to produce high-quality cubic machine-made sand. In order to improve production efficiency and product quality, the NW8HRC equipment also introduces the IC™ automated process control system, which can monitor and adjust various key parameters in the crushing process in real time, including crushing force, crushing chamber shape, and material flow, thereby optimizing production efficiency, improving product quality, and ensuring the stability of the final product quality.

NW8HRC NW Rapid Mobile Cone Crusher Parameters

| Transport length | 11,592 mm (38' 0) | Transport width | 2,540 mm (8' 4") |

| Transport height | 3,990 mm (13' 1") | Transport weight | 30,250 kg (66,690 lbs.) |

| Bogie weight | 17,600 kg (38,802 lbs.) | King pin weight | 12,650 kg (27,888 lbs.) |

| Feed opening | 32 mm (1.3") | Motor power | 2 x 75 kW (2 x 100 hp) |