PE1500×1800 Jaw Crusher with 320MPa Crushing Capacity for Coarse Crushing of Ore, Suitable for Multiple Industries

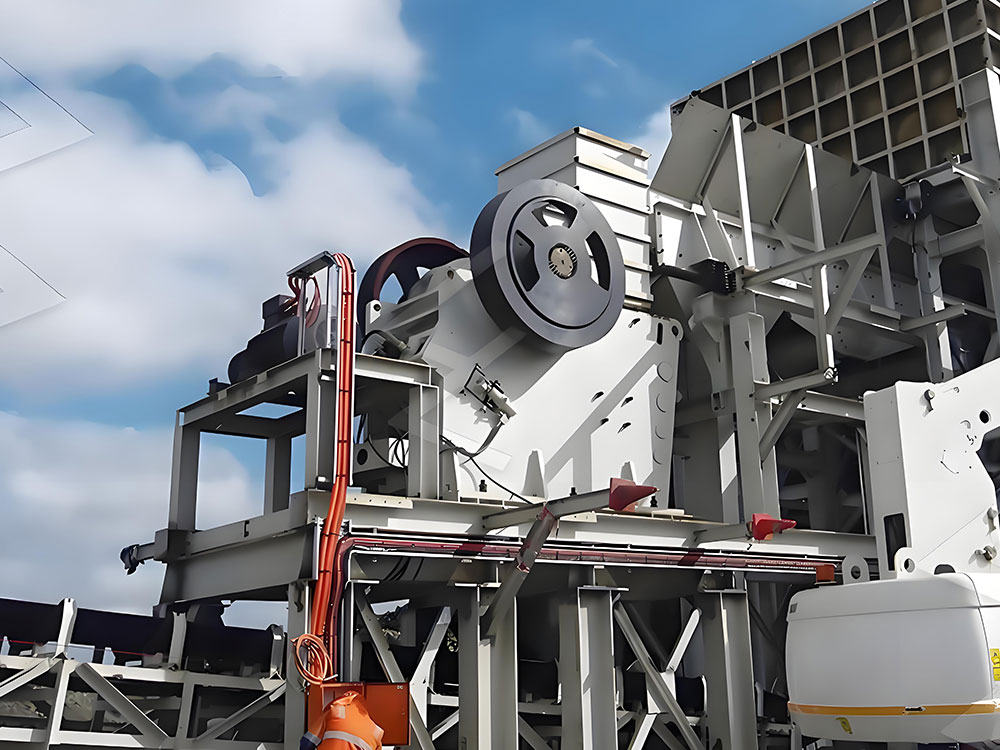

The PE1500×1800 jaw crusher is a large-scale compound pendulum coarse crushing machine designed for mining, metallurgy, construction, and other industries. It efficiently crushes various ores and rocks with compressive strengths ≤320MPa. Key specifications include: feed size ≤1200mm, capacity 500-1200 t/h, motor power 280-355 kW, adjustable discharge size 220-350mm, and total weight approximately 140 tons. Featuring a deep cavity dead-zone-free design, it incorporates a hydraulic adjustment system and centralized lubrication, delivering both high crushing efficiency and energy savings. Ideal for the primary stage of sand and gravel production lines, it often operates in conjunction with cone crushers and other equipment.

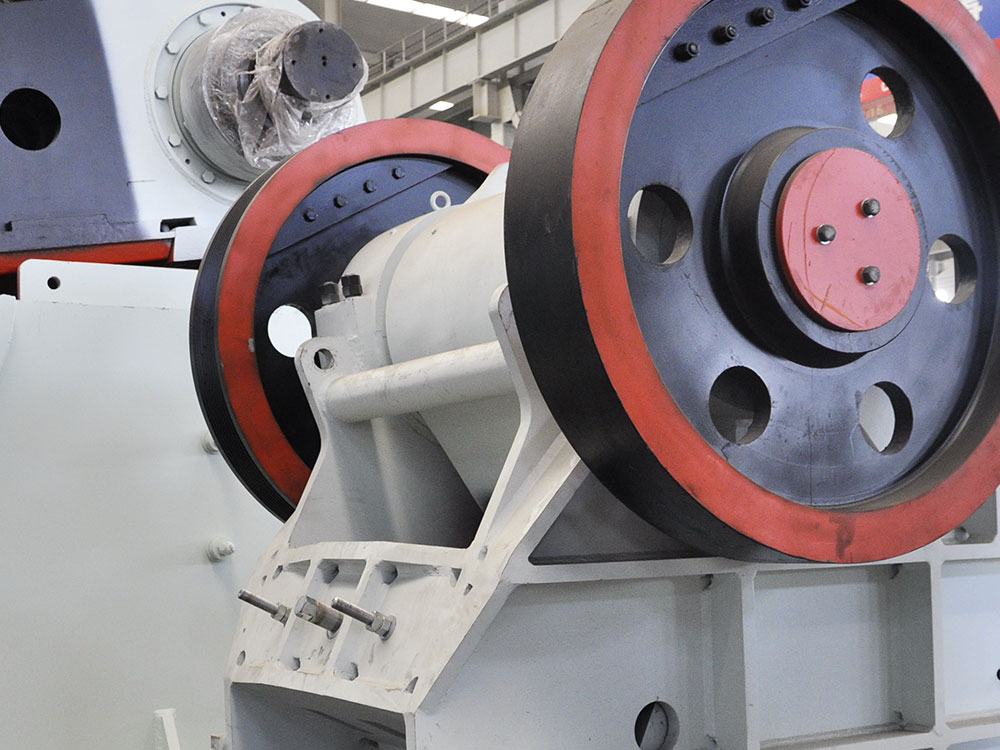

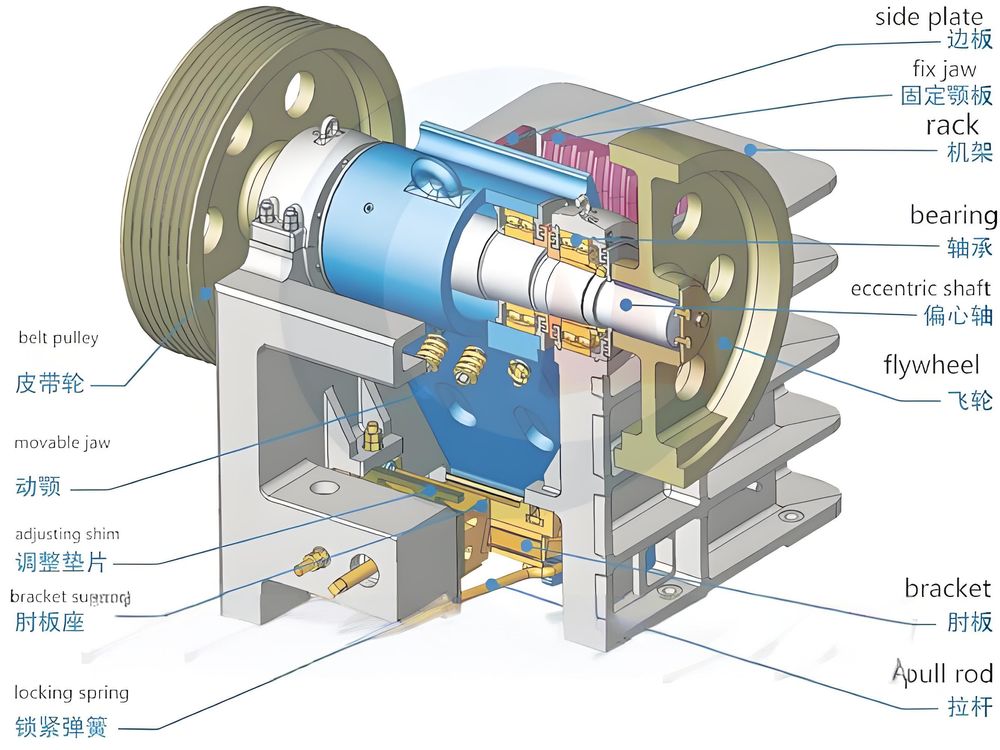

This equipment employs a compound pendulum motion structure, comprising a frame, eccentric shaft, movable jaw plate, and a safety-equipped toggle plate. Its core working principle involves: the motor driving the pulley to rotate the eccentric shaft, causing the movable jaw plate to move along an elliptical trajectory. Materials are crushed through multiple forces including compression and grinding. Compared to simple pendulum models, the compound pendulum structure offers three key technical advantages: First, the more complex motion trajectory of the movable jaw increases crushing efficiency by 20-30%. Second, its lighter weight and compact design facilitate transportation and installation. Third, the deep-cavity V-shaped design minimizes dead zones, while the hydraulic adjustment mechanism enables rapid discharge opening adjustment. Critical components, including manganese steel alloy jaw plates and integral cast steel bearing housings, ensure high crushing strength and operational stability. Additionally, the wedge-type discharge opening design replaces traditional slide gate structures. Combined with a centralized lubrication system, it significantly reduces maintenance complexity and downtime.

For model selection and maintenance, the PE1500×1800 jaw crusher requires matching motor power and discharge parameters to specific production needs. Routine maintenance focuses on bearing lubrication and jaw plate replacement, while monitoring operating temperatures to ensure they do not exceed 70°C. Its hydraulic overload protection system automatically handles sudden overloads, while the centralized lubrication system effectively reduces friction wear. This equipment is particularly suited for coarse crushing operations in large-scale mining. When paired with cone crushers, it can form an efficient aggregate production line. However, note that feed size must be controlled below 1200mm to prevent equipment overload.

PE1500×1800 Jaw Crusher with 320MPa Crushing Capacity for Coarse Crushing of Ore, Suitable for Multiple Industries Applications

Core Crushing Force in Mining Operations

This equipment is specifically designed for medium-to-high hardness ores with compressive strength ≤320MPa, demonstrating significant advantages in the primary crushing stage of metal mines such as iron and copper. Featuring high-manganese steel jaw plates and a hydraulic adjustment system, it processes raw ore with a maximum feed size of ≤1500mm, controlling the discharge size within the 100-300mm range to provide ideal feed for subsequent medium and fine crushing stages. Application data from a major iron ore mine indicates this equipment increased production line capacity by 23% and reduced crushing costs per ton of ore by 18%.

Front-End Processing Expert for Metallurgical Industries

During raw material preparation for metal smelting, the equipment achieves efficient crushing of iron ore, copper ore, and similar materials through its triple crushing chamber design. Specifically for magnetite with iron content >30%, wear-resistant liner combination technology extends hammer plate lifespan to over 1,500 hours. A copper smelter case study demonstrates that crushed ore achieves 85% particle size uniformity, significantly improving subsequent ball mill grinding efficiency.

Aggregate Processing Hub for Building Materials Production

Construction Aggregate Preparation: Achieves ≥92% crushing yield for hard rocks like granite and basalt, with over 70% of aggregates in the 5-31.5mm size range, fully meeting C50 concrete aggregate standards.

Cement Raw Material Processing: After limestone crushing, 80% of particles ≤10mm, with a 15% improvement in raw material grindability index. This reduced coal consumption per ton of clinker by 1.2kg at a cement plant.

Foundation Assurance for Infrastructure Projects

By optimizing crankshaft speed (280-320 r/min) and eccentricity (45mm), hammer wear is reduced by 40% compared to conventional equipment when crushing high-silica rocks like river pebbles and quartzite. Subgrade fill processed by this equipment for the Chengdu-Chongqing High-Speed Railway maintained compaction rates above 98% for three consecutive months.

Multifunctional Processing Platform for Chemical and Energy Sectors

Coal Gangue Crushing: By adjusting grate bar spacing (20-50mm), achieves ≥90% particles under 30mm, providing ideal fuel for gangue power generation.

Desulfurization Agent Preparation: Achieves a limestone crushing ratio of 1:8, increasing specific surface area by 25%. This boosted desulfurization efficiency by 12% at a power plant.

Chemical Raw Material Processing: Utilizing the laminar principle for quartz sand crushing, iron content in the final product is controlled below 0.03%, meeting photovoltaic glass raw material standards.

PE1500×1800 Jaw Crusher with 320MPa Crushing Capacity for Coarse Crushing of Ore, Suitable for Multiple Industries Advantages

I. High-Efficiency Crushing Performance

Deep Cavity Design with Zero Dead Zones

Optimized deep cavity structure boosts feed capacity, increasing crushing efficiency by 30% and achieving 20% energy savings per unit.

Compound Pendulum Motion Trajectory

The moving jaw plate follows an elliptical trajectory, enabling multi-stage crushing through squeezing and grinding. Capacity ranges from 500-1200 t/h.

High-Manganese Steel Jaw Plates

Premium high-manganese steel castings extend core component lifespan by over 60%.

II. Intelligent Adjustment System

Hydraulic Discharge Adjustment

Shim-type discharge opening device (adjustable 220-350mm) enables rapid adaptation to varying particle size requirements.

Overload Protection Mechanism

Automatic breakaway design for the elbow plate ensures equipment shutdown upon encountering non-crushable materials.

Centralized Lubrication System

Quantitative oil injection reduces friction wear, cutting maintenance workload by 50%

III. Stable and Reliable Structure

Heavy-Duty Eccentric Shaft Design

Forged blank processed eccentric shaft paired with cast steel moving jaw assembly, boosting load capacity by 40%

Modular Assembly

Standardized component design enables replacement of wear parts like jaw plates in just 2-3 hours

Low Noise & Eco-Friendly

Complies with national environmental standards, reduces dust emissions by 30%

IV. Wide Applicability

Compressive Strength 320MPa

Crushing capability for hard rocks like granite and basalt, suitable for mining, construction materials, and other industries

Production Line Compatibility

Serves as primary crushing equipment, integrates with cone crushers, sand makers, and other machinery to form complete production lines

PE1500×1800 Jaw Crusher with 320MPa Crushing Capacity for Coarse Crushing of Ore, Suitable for Multiple Industries Works Principle

The working principle of the PE1500×1800 jaw crusher is based on a compound pendulum motion mechanism. Material crushing is achieved through the periodic squeezing action between the moving jaw and fixed jaw, with the process divided into three distinct stages: As the movable jaw approaches the fixed jaw, the crushing chamber volume decreases, subjecting materials to crushing, bending, and splitting forces; the compound pendulum motion trajectory simultaneously applies compression, grinding, and impact forces to materials, enhancing crushing efficiency; when the movable jaw retracts, the crushing chamber expands, allowing crushed materials to discharge through the outlet under gravity. Forged steel eccentric shaft ensures stable movable jaw motion trajectory, increasing load capacity by 40%. The discharge opening (220-350mm) allows rapid adjustment via the hydraulic system to control final particle size. The symmetrical tooth-shaped liner design extends service life and can be flipped for reuse after wear. This equipment achieves batch production through a continuous cycle of compression and discharge. Its compound pendulum motion trajectory improves crushing efficiency by 20-30% compared to simple pendulum crushers.

PE1500×1800 Jaw Crusher with 320MPa Crushing Capacity for Coarse Crushing of Ore, Suitable for Multiple Industries Technical Parameters

| Feed opening size | 1500×1800 mm | Feed size | ≤1200 mm |

| Discharge opening size | 210-360 mm | processing capacity | 520-1100 t/h |

| Motor power | 280 kw | Weight | 132 t |