Primary crushing CG820i gyratory crusher

The CG820i gyratory crusher has set a new benchmark in the field of coarse crushing in mines with its excellent performance and efficient processing capacity. Its maximum processing capacity is as high as 4,000 tons/hour, which fully demonstrates the powerful strength of the CG820i in crushing operations. In order to meet the mine's demand for crushing large pieces of materials, the equipment is specially designed to adapt to the 1,372 mm (54 inches) large-piece material feed port. This design not only improves the equipment's processing capacity, but also ensures the smooth progress of the crushing operation.

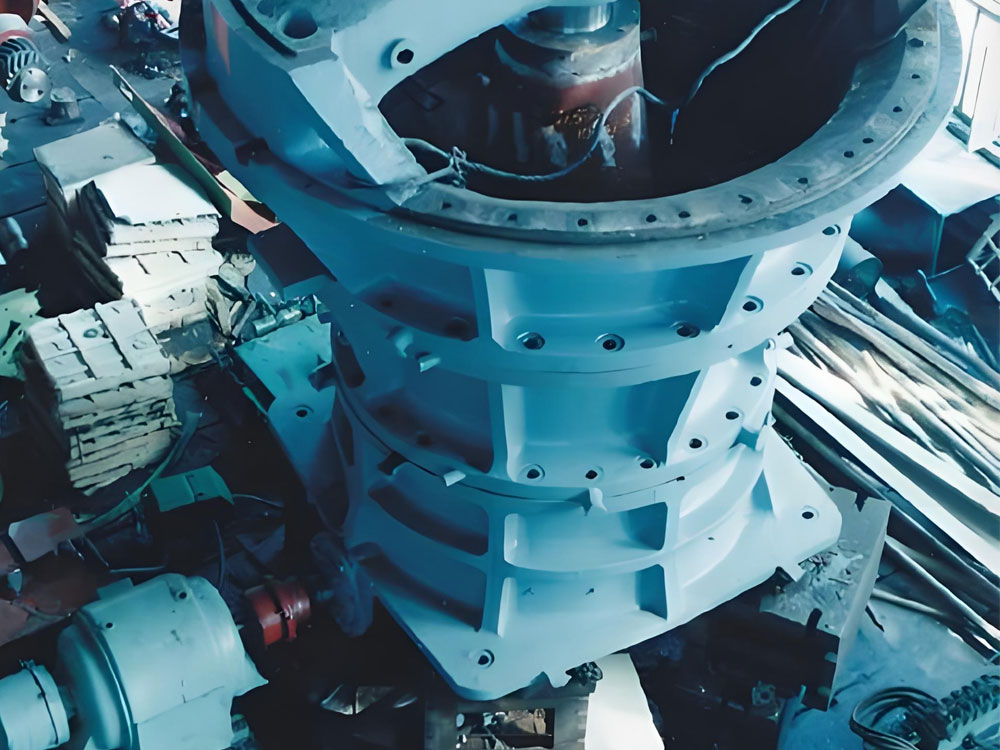

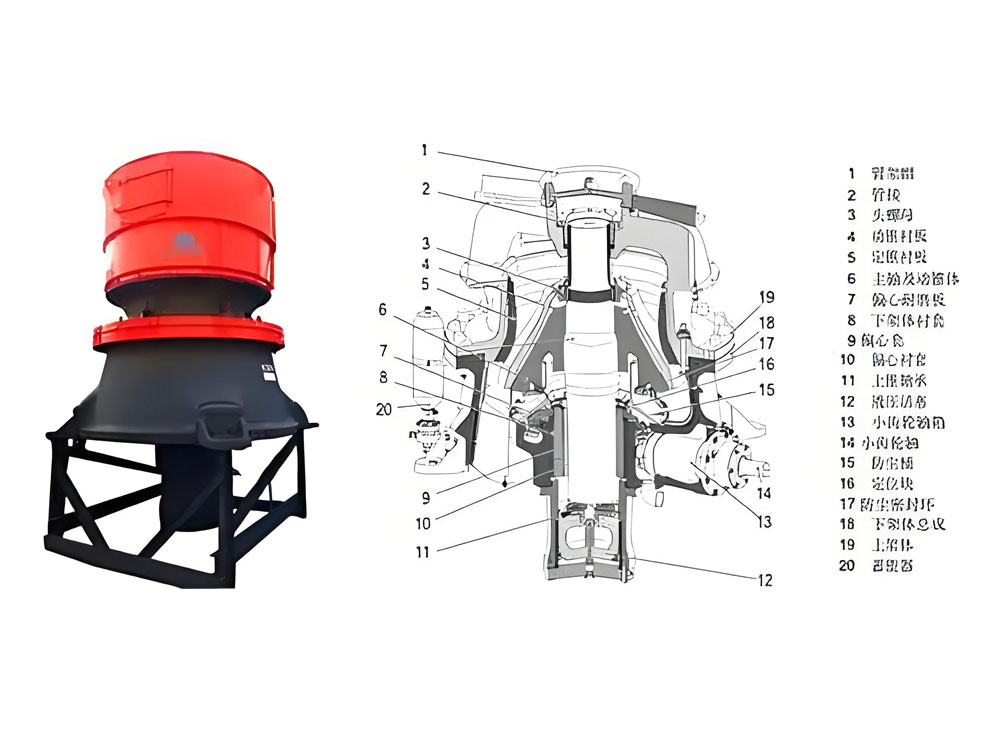

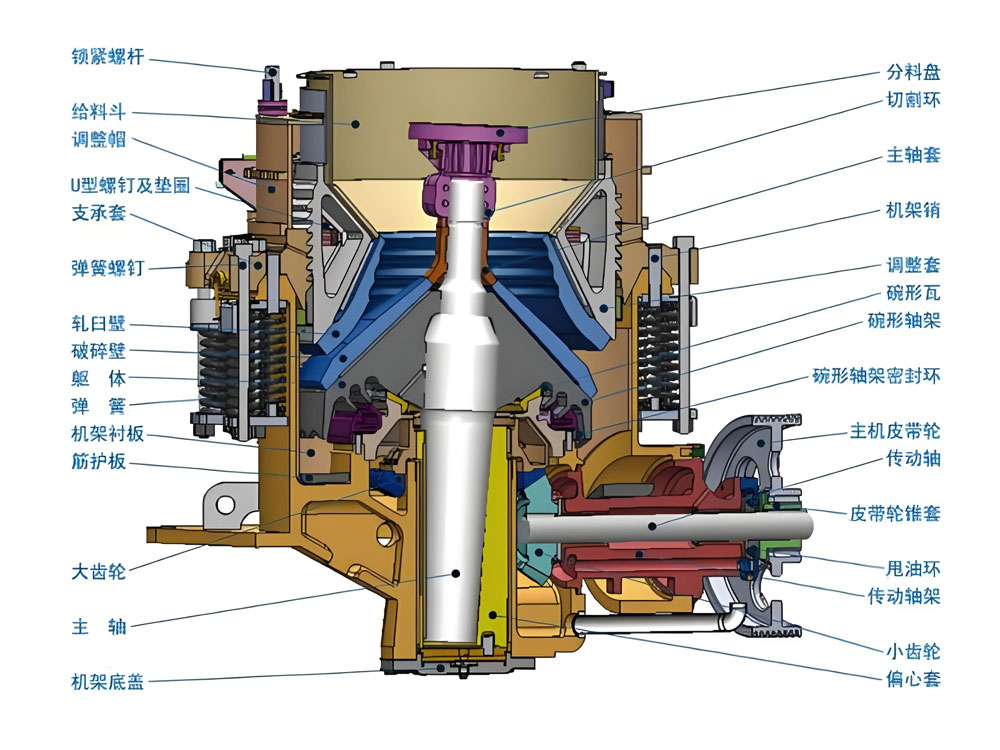

In terms of structural design, the CG820i adopts a heavy-duty main shaft support structure. The design of this structure fully considers the high-intensity impact and vibration in the crushing operation, ensuring the stability and durability of the main shaft. At the same time, combined with an advanced hydraulic drive system, the CG820i realizes the stable eccentric gyratory motion of the crushing cone. This motion mode not only improves the crushing efficiency, but also makes the crushing force distribution more uniform, further improving the equipment's impact resistance.

In terms of application areas, the CG820i gyratory crusher is particularly suitable for coarse crushing operations of hard rocks such as iron ore and copper ore. Its powerful crushing capacity and stable operating performance allow a single machine to replace multiple traditional jaw crushers, greatly reducing the user's initial investment cost. In addition, the continuous operation characteristics of CG820i enable it to demonstrate extremely high efficiency in the sand and gravel aggregate production line, and its efficiency can be increased by more than 30% compared with traditional models. This advantage not only improves the overall production capacity of the production line, but also brings more significant economic benefits to users.

The hydraulic system of CG820i is designed with full consideration of the actual needs of users. Compared with traditional mechanical adjustment models, the hydraulic system of CG820i can shorten the adjustment time of the discharge port to within 5 minutes. This improvement not only improves the flexibility of the equipment, but also saves users a lot of time and labor costs. At the same time, the hydraulic system also supports remote operation, allowing users to accurately control the equipment at a safe distance, further improving the safety and efficiency of the production line.

In addition, the modular design of CG820i is also a highlight. This design not only facilitates the transportation and on-site assembly of the equipment, but also makes it more convenient and quick for users to maintain or replace parts. Especially for remote mining areas, modular design greatly reduces the difficulty of equipment installation and maintenance, ensuring the stable operation of the production line.

Primary crushing CG820i gyratory crusher Applications

First, in the primary crushing of hard rocks such as iron ore and copper ore, CG820i can easily cope with large-scale crushing operations with its powerful crushing capacity and single-machine processing capacity of up to 4,000 tons/hour. Its high crushing efficiency can not only meet the needs of coarse crushing in mines, but also directly replace multiple traditional jaw crushers, thereby significantly reducing equipment investment costs and improving overall economic benefits.

The laminated crushing principle and continuous operation characteristics adopted by CG820i make the particle size of the crushed materials uniform, meeting the needs of mines to directly enter the grinding or beneficiation process after coarse crushing. This feature not only improves the overall efficiency of the production line, but also ensures the stability and reliability of subsequent process flows.

In the primary crushing of metallurgical raw materials, CG820i also performs well. Its large feed inlet design (1,372 mm) can easily adapt to irregular large pieces of materials, ensuring the standardization of raw material specifications in the front stage of smelting. This advantage is of great significance to improving smelting efficiency and reducing energy consumption.

In the sand and gravel aggregate production line, CG820i achieves high output (1,500-4,000 tons/hour) through continuous extrusion crushing. With advanced screening equipment, the equipment can significantly improve the production line efficiency by more than 30%. This feature makes CG820i an ideal choice for highway and railway roadbed aggregate processing. Its efficient crushing capacity and stable operating performance ensure the quality and output of aggregates, providing a strong guarantee for infrastructure construction.

In addition, CG820i is also suitable for crushing medium-hard raw materials such as limestone and gypsum. Its wear-resistant liner design not only improves the durability of the equipment, but also reduces the maintenance frequency of highly corrosive materials. This feature makes CG820i also widely used in chemical reactions, cement raw material preparation and other fields.

When processing solid waste such as construction waste and waste ore, CG820i shows its environmental protection and high efficiency. Through the hydraulic overload protection function, the equipment can automatically discharge metal foreign matter to avoid equipment damage. At the same time, combined with the dust prevention system, CG820i effectively reduces secondary pollution and meets green production standards. This feature makes CG820i have broad application prospects in the fields of urban solid waste treatment, resource recycling, etc.

Primary crushing CG820i gyratory crusher Advantages

High capacity and bulk material handling capability

In the field of crushing equipment, the CG820i gyratory crusher stands out for its excellent high capacity and bulk material handling capability, becoming the preferred equipment in many industrial applications. Its single-machine processing capacity is as high as 4,000 tons/hour, and its wide feed opening design of 1,372 mm enables the equipment to easily cope with the crushing needs of large hard rock ores (such as iron ore and copper ore), and its efficiency is significantly higher than that of traditional jaw crushers.

The reason why the CG820i can perform well in handling large pieces of materials is inseparable from the lamination crushing principle it adopts. Through continuous extrusion, the equipment can significantly reduce the idling phenomenon of materials during the crushing process, thereby ensuring that the finished product has uniform particle size and the average particle size can be controlled below 150 mm. This feature not only improves the crushing efficiency, but also reduces the pressure of subsequent processes, providing a strong guarantee for the stable operation of the entire production line.

Intelligent operation and remote management

In terms of intelligence, the CG820i gyratory crusher integrates the My Sandvik digital platform to achieve real-time monitoring of equipment operation. Through this platform, users can easily obtain key parameters such as bearing temperature and lubrication status, so as to timely discover and solve potential problems. In addition, the device can also automatically generate equipment health reports and maintenance recommendations to help users arrange maintenance plans reasonably, reduce unplanned downtime, and improve production efficiency.

It is worth mentioning that CG820i also supports the remote adjustment function of the hydraulic system. Users can quickly adjust the size of the discharge port (ranging from 140-250 mm) through remote operation according to actual needs to meet the needs of different working conditions. This feature not only improves the flexibility of the production line, but also saves users a lot of time and labor costs.

Structural design and stability advantages

In terms of structural design, the CG820i gyratory crusher adopts a combination design of heavy-duty main shaft and balance cylinder system. This design can not only effectively prevent abnormal vibration of the main shaft, but also automatically slow down to protect the core components when overloaded, ensuring that the equipment can still operate smoothly under extreme working conditions. In addition, the device also adopts a deep cavity and long feed port design to further improve the material passing rate. With the use of wear-resistant alloy liners, the service life of the liners can be extended to 6-12 months, greatly reducing the maintenance frequency of users.

Easy maintenance and safety

In terms of maintenance convenience, the CG820i gyratory crusher adopts a hydraulic beam separator and a removable conical locking nut design. This design allows users to easily replace bushings or seals without removing the beam, thereby greatly shortening downtime for maintenance. At the same time, the equipment is also equipped with a positive pressure dust prevention system, which effectively blocks the possibility of dust entering key components such as bearings. Combined with the use of a centralized lubrication system, the risk of component wear is further reduced and the overall durability of the equipment is improved.

Environmental protection and energy consumption optimization

In terms of environmental protection and energy consumption, the CG820i gyratory crusher also performs well. The equipment is equipped with a noise reduction module and a closed dust prevention structure, which reduces production noise to below 85 decibels, and dust emissions are also fully in line with green mine standards. In addition, compared with traditional jaw crushers, the unit energy consumption of CG820i is reduced by 30%-40%, bringing significant long-term operating cost advantages to users.

Primary crushing CG820i gyratory crusher Working Principle

CG820i gyratory crusher is an efficient and stable crushing equipment. Its core working principle lies in the eccentric gyratory motion of the crushing cone. The crushing cone is placed in the eccentric hole of the sleeve through the lower end of the main shaft. When the main shaft rotates, the crushing cone will perform eccentric gyratory motion around the center line of the machine. This motion mode forms a continuous extrusion, splitting and bending effect, so that the material is subjected to all-round crushing force in the crushing chamber.

The cooperation between the moving cone and the fixed liner forms a progressive crushing chamber, and the material is crushed step by step from top to bottom to the target particle size. In this process, the upper end of the main shaft is stably supported by the crossbeam bushing, while the lower end is closely connected to the hydraulic drive system through the eccentric sleeve to ensure the stability of the power output and effectively avoid abnormal vibration of the main shaft.

When the material enters the crushing chamber, it will be repeatedly squeezed and impacted by the eccentric gyratory motion of the moving cone. Especially for hard-to-crush materials such as hard rock ores (such as iron ore), CG820i adopts the principle of laminated crushing, and gradually crushes the materials to the required particle size through continuous extrusion and impact. This crushing method not only improves the crushing efficiency, but also makes the particle size of the crushed materials more uniform, meeting the strict requirements for material particle size in different fields.

During the crushing process, the compressive strength of the material will be gradually broken (for example, the compressive strength of iron ore is about 250MPa). With the mutual friction and extrusion between particles, the material is further refined until the target particle size is reached. The meshing angle formed between the moving cone and the fixed cone liner optimizes the direction of the crushing force, so that the material is mainly subjected to shear and bending stress, thereby reducing energy loss and improving crushing efficiency.

The CG820i gyratory crusher is also equipped with an advanced hydraulic adjustment system. By adjusting the height of the main shaft through the hydraulic cylinder, the distance between the moving cone and the fixed cone can be changed (that is, the discharge port range is between 140-250 mm), so as to accurately control the discharge particle size. This function enables the equipment to flexibly adapt to different working conditions and material requirements, providing users with more options.

In addition, when foreign matter (such as metal blocks) enters the crushing chamber, the hydraulic system of CG820i can respond quickly. The accumulator will release pressure, causing the crushing cone to automatically drop and expand the discharge port, thereby quickly discharging foreign matter and avoiding equipment damage. This design not only improves the safety of the equipment, but also reduces the downtime caused by foreign matter jamming, further improving the reliability and stability of the equipment.

Primary crushing CG820i gyratory crusher Technical Parameters

| Feed opening | 1,372.0 mm | Capacity | 1500 t/h |

| Power | 525 kw | Open side setting | 125.0 - 215.0 mm |

| Horizontal Shaft | 500 rpm | Weight | 244 t |