The best channel to buy LT105 mobile jaw crusher Production capacity

The LT105 mobile jaw crusher is a high-performance crawler-mounted crushing machine designed for medium-scale crushing operations. Its powerful crushing capacity and excellent mobility make it an ideal choice for the mining, building demolition, road construction and recycling industries. The equipment is equipped with a sturdy jaw crusher that can efficiently handle a variety of rocks and ores, especially for medium-hard to high-hard materials. The core advantages of the LT105 lie in its excellent production capacity and flexibility. Its crawler design enables it to move freely in various complex working environments, greatly improving work efficiency. Whether in a narrow work site or a harsh working environment, the LT105 can perform well. In addition, the equipment has a compact structure, is easy to transport and assemble, and is suitable for rapid deployment, saving time and cost. This crusher also has an efficient power system and intelligent control system, ensuring efficient operation and low fuel consumption of the equipment. The LT105 is also very convenient for maintenance, with a modular design that reduces downtime and improves work efficiency. In general, Lokotrack LT105 mobile jaw crusher is a device that combines high efficiency, reliability and economy. It is widely used in ore crushing, construction waste treatment and other large-scale crushing projects, helping users achieve higher production efficiency and reduce operating costs.

LT105 mobile jaw crusher Advantages

Efficient crushing capacity

The LT105 mobile jaw crusher is equipped with a sturdy jaw crusher with powerful crushing capacity, capable of handling a variety of medium-hard to high-hard rocks and ores. Whether it is crushing granite, limestone or construction waste, the LT105 can complete the operation quickly and efficiently, ensuring the production efficiency of each batch of materials. Its superior crushing performance makes the equipment particularly outstanding in various complex operations.

Excellent mobility

As a crawler crusher, the LT105 mobile jaw crusher has extremely high mobility and can move freely in different terrains and working environments. Whether it is an urban demolition site or a remote mountainous area, the LT105 can respond flexibly. Its compact structure allows the equipment to easily pass through narrow spaces, quickly adapt to complex construction conditions, and reduce the constraints of the work site.

Easy to transport and deploy

The design of the LT105 mobile jaw crusher emphasizes transportation convenience. Due to its compact size and reasonable structural layout, the equipment can be easily disassembled, transported and installed, saving time and cost for transportation and deployment. It is particularly suitable for projects that require frequent changes in work sites, and can be quickly assembled and put into use, greatly improving construction efficiency.

Energy saving and low maintenance cost

LT105 mobile jaw crusher adopts an efficient power system, which can achieve low fuel consumption while maintaining high production efficiency. In addition, the equipment adopts a modular design, which is easy to repair and replace parts, reducing the complexity of daily maintenance. Its low maintenance cost and long service life further reduce operating costs, allowing users to obtain higher economic benefits in long-term use.

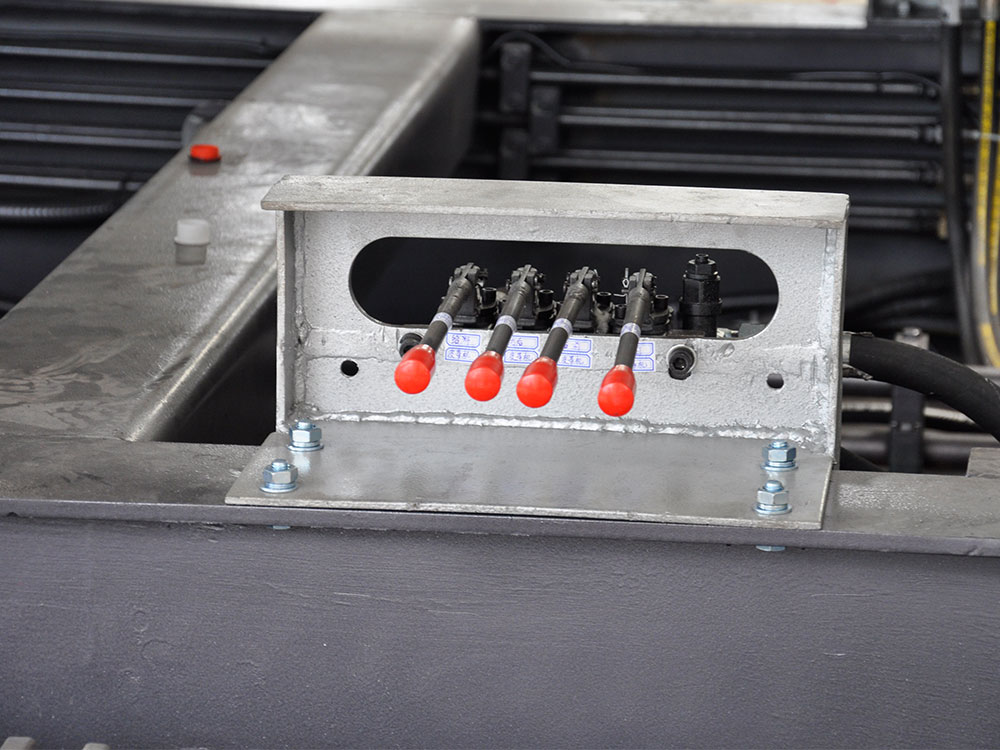

Intelligent control system

LT105 mobile jaw crusher is equipped with an advanced intelligent control system, which is easy to operate and can monitor the operating status of the equipment in real time. Through the integrated control panel, the operator can quickly adjust the crushing parameters to ensure that the equipment is always in the best working condition. At the same time, the system also has a fault diagnosis function, which can promptly detect and solve potential problems, reduce equipment downtime, and improve overall production efficiency.

LT105 mobile jaw crusher Working principle

The Lokotrack LT105 mobile jaw crusher uses the classic jaw crushing principle for material processing. Its core part is a jaw crusher consisting of a fixed jaw plate and a movable jaw plate. When working, the movable jaw plate swings back and forth on the fixed jaw plate through the eccentric shaft, forming a compression and shearing effect, and gradually crushing the material into the required size. Specifically, the working principle of LT105 is as follows: the material is first fed into the feed port and enters the crushing chamber. As the movable jaw plate swings, the material is compressed between the fixed jaw plate and the movable jaw plate and gradually crushed. During the crushing process, larger particles will be squeezed and impacted, and gradually compressed into smaller particles. At the bottom of the crushing chamber, the crushed material is discharged through the discharge port. The eccentric shaft device of the crusher is responsible for driving the swinging movement of the movable jaw plate. Its driving method usually adopts an electric motor through a belt and gear to ensure efficient and stable operation of the equipment. By adjusting the size of the discharge port, the particle size of the crushed material can be controlled to meet different production needs. In addition, the structural design of LT105 emphasizes durability, and important working parts such as jaw plates, bearings and crushing chambers are precisely designed and made of high-strength materials to ensure the reliability and efficiency of the equipment in long-term high-load operation. Overall, the working principle of LT105 enables it to have efficient production capacity and excellent operating stability in medium-scale crushing tasks.

LT105 mobile jaw crusher Technical parameters

| Output | 250-400t/h | Feed port size | 40-150mm |

| Feed size | 40-150mm | Motor power | 200kW |

| Discharge size | 0-150mm | Machine weight | 42t |

LT105 mobile jaw crusher Cases and customer testimonials

Project background

The project is located in a gold mining area in western Russia. The rocks in the mining area are relatively hard, mainly granite and quartzite. The project requires processing large quantities of ore and crushing it to a particle size suitable for subsequent processing. Due to the complex traffic conditions and high transportation costs in mining areas, the use of mobile crushers has become a very ideal choice.

broken mission

As a crawler-type mobile crusher, LT105 is perfectly adapted to the complex terrain of the mining area and avoids the complex installation and transportation work required by traditional fixed crushing stations. This equipment is used for the preliminary crushing of ore. Through its powerful crushing capacity, the ore is broken from raw material blocks to a particle size suitable for subsequent processing, which significantly improves the processability of the ore. Russia's climate conditions are extremely harsh, with winter temperatures often falling as low as -40°C. Despite this, the LT105 still operates stably in low temperature environments. Its strong cold-resistant design and high-quality components allow the equipment to maintain efficient operation in harsh climate conditions.

Customer testimonials

"I am also very satisfied with the mobility of the LT105. Since our mining area has a wide operating area, the equipment needs to frequently operate in different locations. The track design of the LT105 allows it to easily adapt to rough ground, reducing the time and cost of equipment relocation. . Even in the severe cold winter, the equipment can still operate stably and adapt to harsh climate conditions. "

"In terms of operating costs, the fuel consumption of the LT105 is excellent and is much lower than the crushing equipment we used before. In addition, the maintenance of the equipment is relatively simple, and the modular design allows us to easily replace parts, reducing downtime. Overall Overall, the LT105 is an efficient, reliable and economical device and we are very pleased with its performance."