UK373 cone crusher for sale

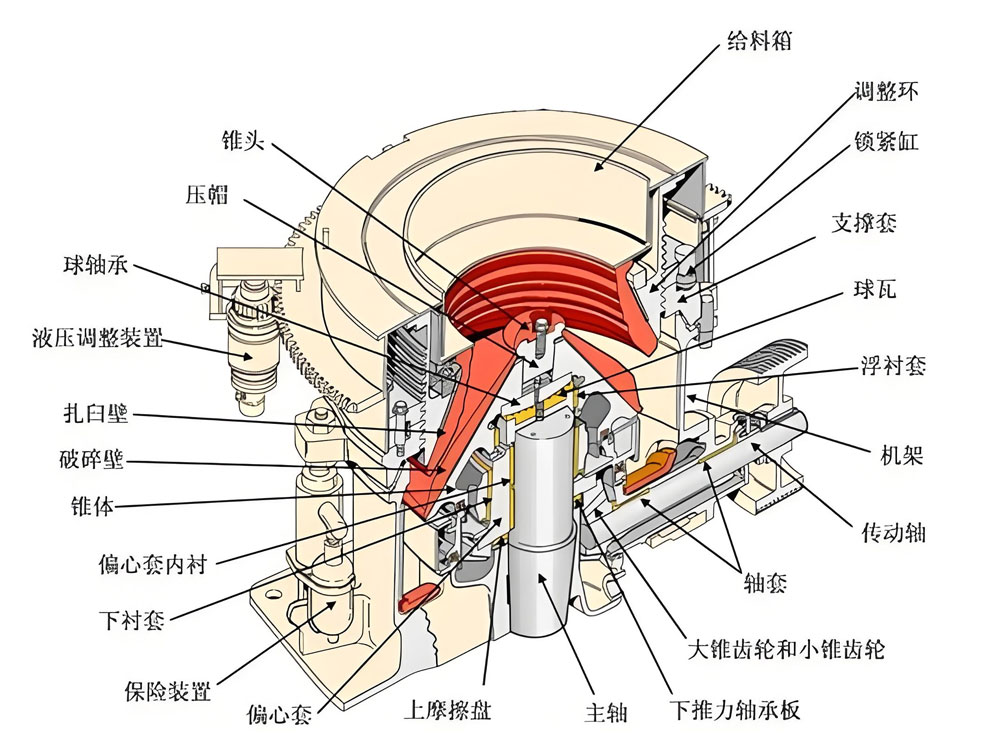

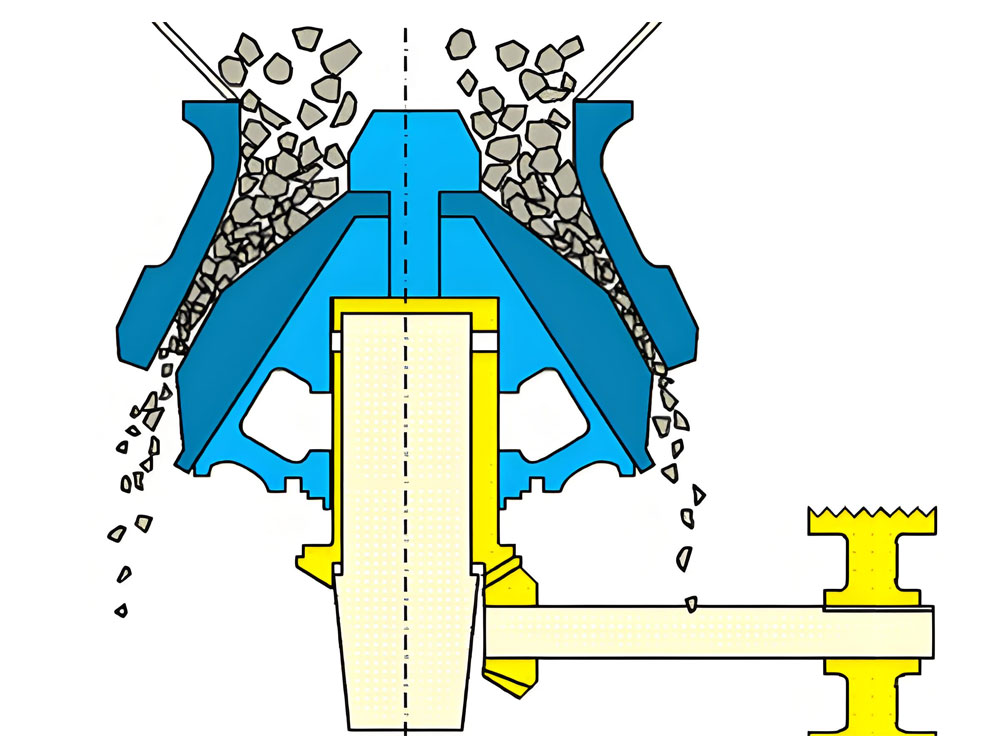

UK373 cone crusher is a type of cone crusher, which inherits the advantages of cone crusher such as large crushing ratio, high efficiency, low energy consumption and uniform product particle size. It is widely used in raw material crushing in industries such as metallurgy, construction, road construction, chemical and silicate, especially in mining, smelting, building materials and other fields. UK373 cone crusher is an efficient ore crushing equipment, suitable for medium and fine crushing of various ores and rocks. UK373 cone crusher is mainly composed of frame, transmission part, eccentric sleeve part, cone crushing part and other parts. These parts work together to ensure that the equipment can operate efficiently and stably. Among them, the cone crushing part is the core part of the equipment. Through the relative movement of the moving cone and the fixed cone, the material is squeezed and impacted to achieve the crushing effect. The working principle of UK373 cone crusher is similar to that of cone crusher. When working, the motor drives the eccentric sleeve to rotate through the transmission device. This rotational movement causes the moving cone to rotate and swing under the push of the eccentric sleeve. When the moving cone approaches the static cone, the area between the two forms a crushing chamber. The material is continuously squeezed and impacted by the moving cone and the static cone in the crushing chamber, thus achieving a crushing effect. Once the moving cone leaves the crushing area, the material that has been crushed to the required particle size falls naturally under the action of its own gravity and is discharged out of the machine through the bottom of the cone.

UK373 cone crusher for sale Applications

In the mining and processing of metal and non-metallic ores, the equipment can effectively handle ores of various hardnesses, such as copper ore, iron ore, bauxite, etc. Its powerful crushing capacity and precise particle size control enable the ore to reach the ideal particle size requirements during extraction and processing, thereby improving the utilization rate and processing efficiency of the ore. In addition, the UK373 cone crusher is also suitable for fine crushing of ore, providing high-quality raw materials for subsequent beneficiation and smelting processes.

In the construction industry, the UK373 cone crusher also performs well. With the acceleration of urbanization, the demand for building aggregates is increasing. The equipment can crush stones into sand and gravel particle sizes that meet the specifications for the production of concrete and asphalt. These high-quality building materials not only improve the overall quality of the building, but also extend the service life of the building. In addition, the UK373 cone crusher can also adjust the discharge port size according to customer needs to produce aggregates of different particle sizes to meet diverse construction needs.

Highway and railway construction is also one of the important application areas of the UK373 cone crusher. In the process of highway and railway construction, a stable supply of aggregate is the foundation. This equipment can provide high-quality and uniform aggregate to ensure the stability and durability of the roadbed of highways and railways. At the same time, the high-efficiency crushing capacity and low energy consumption of the UK373 cone crusher also reduce construction costs and improve engineering benefits.

UK373 cone crusher for sale Advantages

Hard rock high-efficiency crushing system

The equipment adopts a multi-cavity laminated crushing structure, combined with a dynamic optimization crushing trajectory algorithm, so that the material forms a stepped extrusion collision in the cavity, the crushing ratio exceeds 1:15, and the processing capacity of a single machine is increased by 30% compared with traditional models. For high-hardness ores such as granite (Mohs hardness 6-7) and basalt (Mohs hardness 7-8), its specially designed serrated liner can expand the impact contact area by 25%, and the maximum daily processing capacity reaches 7,200 tons (feed particle size ≤350mm). The intelligent hydraulic system is equipped with 32 high-precision piezoelectric sensors to monitor the pressure changes in the crushing chamber in real time, and automatically adjust the discharge port (5-60mm accuracy ±0.5mm) through the PID closed-loop control algorithm to ensure that the output is stable in the range of 150-800 tons/hour, with a fluctuation rate of less than 3%.

Composite power and ultra-long durability design

The dual-power drive module supports the mixed operation of diesel engines (300kW) and permanent magnet motors (250kW). The fuel consumption is reduced to 18L/ton when operating in a non-grid mining area. The flywheel kinetic energy recovery system can reduce the overall energy consumption by 18%. The moving cone/fixed cone liner adopts high-chromium alloy steel (surface hardness HRC62+) and nano-carburizing process. The gradient composite technology makes the impact fatigue life reach 12,000 hours, which is 40% higher than the industry standard. Core components such as the 42CrMo4 alloy steel spindle are vacuum degassed, and the bending strength is increased to 980MPa. With SKF customized tapered roller bearings, it can withstand 650 tons of instantaneous impact load.

Intelligent operation and stable operation

The modular quick-release structure shortens the replacement time of the spindle assembly to 4 hours (traditional models require 12 hours), and the eccentric sleeve alignment error is controlled within ±0.02mm. The AR remote guidance system uses Hololens 3 glasses to achieve three-dimensional positioning of the fault point. The cloud knowledge base integrates 3000+ case libraries, the diagnostic accuracy rate is increased to 95%, and the average fault repair time is compressed to 1.2 hours. The hydraulic-rubber-electromagnetic triple shock absorption system stabilizes the vibration value of the equipment at 1.8mm/s (better than ISO 10816-3 Class B standard), ensuring seamless linkage with high-precision equipment such as laser particle size analyzers and automatic sorting machines.

Flexible adaptation to multiple scenarios

The mobile configuration integrates an all-terrain crawler chassis (turning radius <6m) and a three-section folding conveyor belt (total length 18m), which can complete the on-site deployment of construction waste treatment within 30 minutes, with a daily processing capacity of 300 tons, and the dust suppression system achieves PM2.5 emissions <10mg/m³. After adding the VSI shaping module, the stone is centrifugally accelerated and crushed at 85m/s, and the fineness modulus of the finished sand is precisely controlled in the range of 2.2-3.0, and the particle grading is 100% in line with the GB/T 14684-2022 Class I sand standard. In actual applications, after using this equipment in a sand and gravel plant in the Yangtze River Basin, the standard deviation of concrete compressive strength dropped from 4.5MPa to 2.8MPa, and the cement consumption was reduced by 12%.

Empirical data and economic benefits

In the continuous operation test in the Panxi vanadium-titanium iron ore area, the equipment availability rate reached 98.7%, and the crushing cost per ton was reduced to 2.3 yuan (the industry benchmark is 3.5 yuan). When the dual-power model operates in the off-grid mining area in Mongolia, the annual diesel consumption is reduced by 150 tons and the carbon emissions are reduced by 120 tons. By quickly switching the crushing chamber type and drive module, the equipment can meet the needs of mining rough crushing, construction waste recycling, fine sand making and other scenarios, helping users shorten the comprehensive investment return cycle to 14 months.

UK373 cone crusher for sale Principle

The K373 cone crusher is equipped with an intelligent dual-power drive module (diesel engine 300kW/permanent magnet motor 250kW), which drives the horizontal shaft through the gear transmission system, driving the eccentric sleeve assembly to achieve 5-60mm dynamic eccentricity adjustment. This design enables the dynamic cone to rotate and swing at a high frequency of 285rpm (29.5% higher than traditional models), forming a three-level progressive crushing space in the crushing chamber. First is the primary extrusion area, where large pieces of ore (≤350mm) are subjected to an instantaneous extrusion pressure of 650 tons in the top cavity, resulting in through cracks (crushing strength 120-150MPa); second is the laminated crushing area, where the crushed materials collide with each other during the cone swing (speed 2.8-3.5m/s), and the secondary crushing rate is <5%; finally, the intelligent shaping area, where the bottom cavity monitors the load in real time through 32 sets of piezoelectric pressure sensors, and the PID closed-loop control system adjusts the hydraulic cylinder thrust with a response speed of 0.1 seconds, dynamically compensates for the eccentricity and accurately controls the discharge port (5-60mm±0.5mm). The system can identify hard rock conditions such as granite (compressive strength ≥250MPa), compress the output fluctuation rate to ±3%, and stably output 150-800 tons/hour of finished products with a particle size qualification rate of ≥98%. The flywheel kinetic energy recovery system is installed simultaneously, converting 30% of the inertial energy into electrical energy, reducing the energy consumption per ton of crushing to 0.8kW·h, a year-on-year decrease of 38.5%. According to actual measurements at the Panxi vanadium-titanium iron ore mine, the equipment availability rate reached 98.7% during continuous operation, and the cost per ton was only 2.3 yuan (the industry benchmark is 3.5 yuan), achieving a breakthrough in both efficient crushing and economic benefits.

UK373 cone crusher for sale Technical Parameters

| Weight | 62,500 kg | Capacity | 520t/h |

| Power | 314 kW | length | 71.1 ft |

| width | 12.6 ft | height | 14.5 ft |