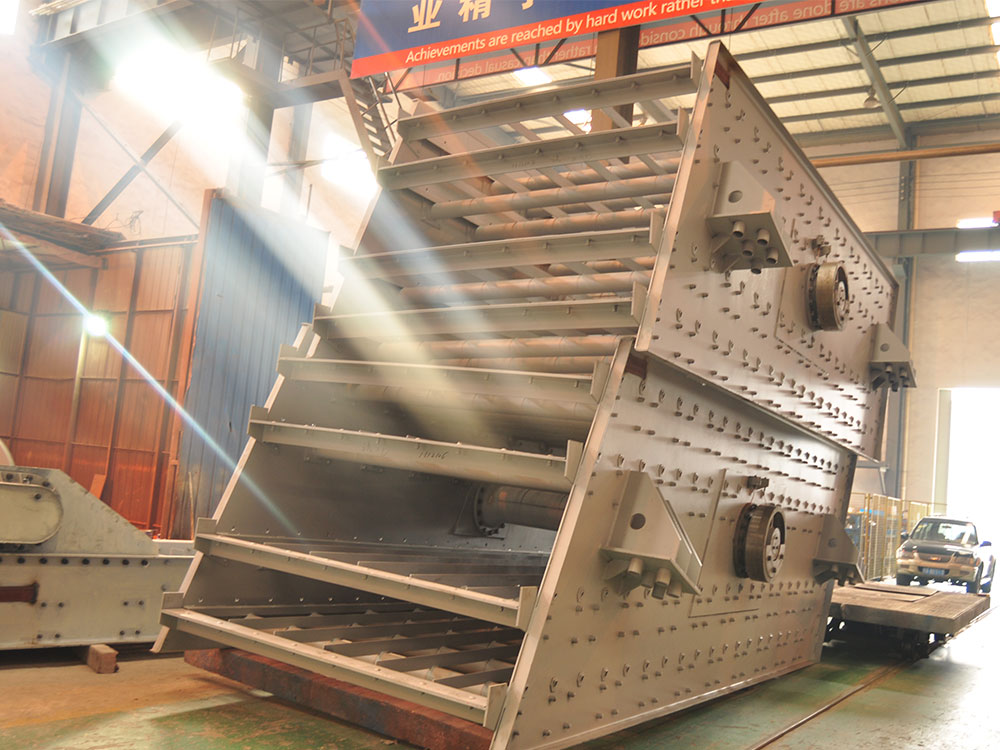

VG Series Circular Vibrating Screen

The VG series circular vibrating screen adopts the international cutting-edge mature design concept and is widely used in various operating scenarios such as heavy-duty, medium-duty and fine screening. It is the preferred equipment for material processing after primary crushing and secondary crushing, and is also suitable for screening of finished materials. It is often used as a supporting equipment for push feeders, plate feeders or vibrating plate feeders. Among them, the primary screening screen designed for the most stringent application environment has excellent performance in both fixed and mobile crushing equipment with its high capacity and excellent abrasive material handling capabilities.

VG Series Circular Vibrating Screen Advantages

Modular design improves versatility and maintenance convenience

The SV vibrator achieves rapid assembly through modular design, has a vibration intensity of up to 4.2G, powerful processing capacity, and high screening efficiency. The exciter replacement process only takes one hour, and the modular design reduces the types of spare parts, improves versatility and reduces maintenance costs.

Integrated frame construction to enhance carrying capacity

Using an overall frame structure design, the load-bearing capacity is significantly improved compared with traditional single beams. Combined with finite element strength analysis technology, it ensures the reasonable distribution of equipment weight and strength and improves overall stability.

All-round high-strength protection to ensure safety and stability

The flexible drive design effectively protects the motor from external impacts, and the exciter guard and pulley guard increase safety. The polyurethane shield, battens and support strips together form a wear-resistant protective layer to improve the durability of the equipment.

Laser cutting technology eliminates the risk of cracking

The side panels adopt advanced laser cutting technology and do not require welding. All reinforcing members are fixed with high-strength torsion shear bolts, which not only makes the installation process simple and fast, but also has higher strength. This design effectively avoids the cracking problem that may be caused by traditional welding.

VG Series Circular Vibrating Screen Working Principle

The VG series circular vibrating screen consists of multiple key components, including a screen box, a spring support system, a support structure, a vibration generator, a transmission mechanism, a motor, and a transmission support. It uses springs as elastic supports and an eccentric vibrator as a power source. The high-speed rotation of the eccentric block generates an exciting force to drive the screen box to perform continuous circular reciprocating motion. On the inclined screen surface, the material will continuously bounce and tumble in a nearly circular manner. During this process, the material will be repeatedly compared with the screen holes. Materials smaller than the size of the screen holes will fall through the screen holes, while materials larger than the size of the screen holes will be retained on the screen surface, thereby achieving an efficient screening process.

VG Series Circular Vibrating Screen Technical Parameters

| degree of automation | automation | power (output) | 55 |

| mesh | 75 | Sieve length | 2m |

| Width (meters) | 1,6 | Material trajectory | elliptic level (math.) |

VG Series Circular Vibrating Screen Cases and customer testimonials

Shaanxi Baoji River Pebble Sand Making Production Line

The raw materials are crushed by two FH1245 vibrating feeders into two PE750×1060 jaw crushers. The materials smaller than 10mm are screened out by two VG series vibrating screens to obtain the original sand. The rest enter the cone crusher adjustment silo and are transported to three HPT300 cone crushers for secondary crushing. The crushed materials are screened by three VG series 2760-3 vibrating screens. The materials larger than 40mm are returned to the cone crusher for further crushing. The materials smaller than 40mm are shaped and made into sand by three 5X1145 sand making machines through the sand making machine adjustment silo. The final finished product particle size is about 28mm or less.

Customer evaluation: After the project was put into production, the equipment performance was stable and the operation was smooth, creating high profits for us as always. The after-sales service is also getting better and better, more and more considerate, the parts supply speed is fast, and the problem is solved in time. Excellent equipment quality and a sound service system are the two major factors that have always made us choose Liming.