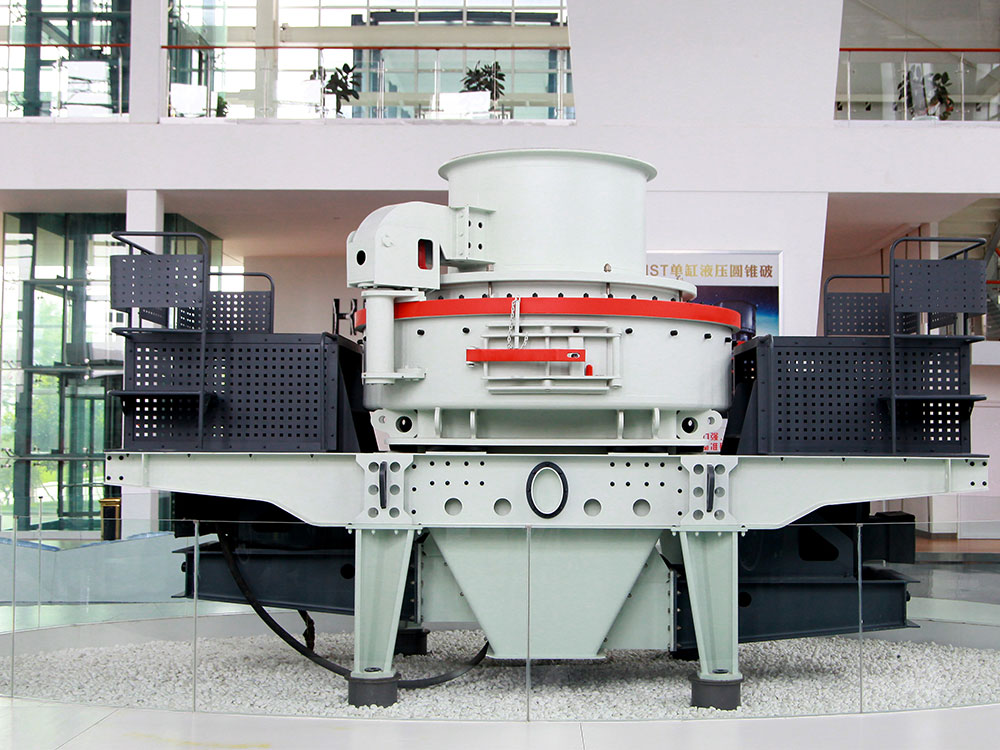

VSI Crusher for sale VSI-9100SE

With its comprehensive advantages of high efficiency, wear resistance, green, energy saving and intelligence, the 9100SE VSI Crusher has firmly established a leading position in the mining and building materials industry and demonstrated unparalleled competitiveness. It can not only significantly improve the production capacity and operating efficiency of the production line, but also bring considerable economic benefits and extensive social value to users. The core of the equipment, the rotor, adopts top-grade materials and cutting-edge manufacturing processes to ensure stable performance and excellent crushing effect under high-intensity operation. The design of the throwing head on the rotor is ingenious, and by optimizing the impact and shearing effect, it can achieve rapid and effective crushing of various materials. At the same time, the wear-resistant plate, as the key protective layer of the equipment, is made of highly wear-resistant materials and specially treated, which effectively resists wear during the crushing process and extends the service life of the equipment. In addition, the advanced lubrication system provides a solid guarantee for the smooth operation of the equipment. It ensures good lubrication and cooling of various parts of the equipment by accurately supplying high-quality lubricating oil, further improving the overall performance and reliability of the equipment.

VSI Crusher for sale VSI-9100SE Applications

In the harsh environment of mining, facing the challenges of ores with different hardness, the 9100SE VSI Crusher stands out with its excellent crushing ability. The equipment adopts cutting-edge vertical shaft impact crushing technology. Through the high-speed rotating rotor and wear-resistant impact blocks, the ore is continuously and efficiently impacted, sheared and ground, which not only significantly improves the crushing efficiency, but also effectively controls the over-crushing phenomenon, ensures the uniformity of the finished ore particle size, and lays a solid foundation for subsequent mineral processing and smelting processes. At the same time, its carefully designed wear-resistant parts greatly extend the life of the equipment, effectively reduce maintenance costs, and improve overall operational efficiency.

With the acceleration of urbanization, the problem of construction waste treatment has become increasingly prominent. The 9100SE VSI Crusher has demonstrated a strong resource utilization capability in this field. It can efficiently convert construction waste such as abandoned concrete and bricks into recycled aggregates. After a series of treatment processes, these aggregates can be widely used in road construction, concrete production and other fields, which not only achieves the reduction and resource utilization of construction waste, but also strongly promotes the green transformation and sustainable development of the construction industry.

In the vast arena of highway and railway construction, high-quality sand and gravel aggregates are an indispensable element to ensure the quality of the project. With its precise crushing control and adjustable output particle size, the 9100SE VSI Crusher can stably produce high-quality sand and gravel aggregates that meet industry standards. These aggregates play a key role in enhancing the strength of pavement structures and improving road durability, providing solid support for the safety and smooth operation of highways and railways. In addition, its high production efficiency meets the large demand for sand and gravel aggregates in large-scale infrastructure construction, accelerates the progress of the project, and helps improve and develop the national transportation network.

In the field of water conservancy project construction, facing the arduous task of processing natural stones such as river pebbles, the 9100SE VSI Crusher also demonstrates extraordinary adaptability and crushing capabilities. It can easily cope with the challenges of crushing large pieces of river pebbles, accurately crushing them to the required particle size range, and providing high-quality material support for embankment reinforcement and bank protection construction of water conservancy projects. At the same time, the equipment focuses on environmental protection performance in its design. The characteristics of low noise and low dust reduce the impact of construction on the surrounding environment, which meets the requirements of modern water conservancy project construction for green construction.

VSI Crusher for sale VSI-9100SE Advantages

Excellent crushing performance

With its innovative crushing chamber configuration and precise rotor design, the 9100SE VSI Crusher achieves a comprehensive, balanced and strong impact and shear effect of materials in the crushing space, leading a new era of efficient crushing. Its crushing efficiency has achieved a qualitative leap compared to traditional models, injecting a strong capacity driving force into the production line, significantly improving production efficiency and output.

Durable material construction

In order to cope with the challenges of harsh working conditions, the key components of the 9100SE VSI Crusher, such as the rotor tip and the upper and lower wear plates, are carefully made of top-grade wear-resistant materials. These materials not only show excellent wear resistance, but also maintain stable performance in long-term high-intensity operations, effectively extending the service life of the equipment, while reducing maintenance frequency and cost, bringing users a more economical and efficient use experience.

Green energy-saving model

In line with the global trend of environmental protection and energy saving, the 9100SE VSI Crusher incorporates cutting-edge green concepts into its design. Through the carefully optimized crushing chamber layout and advanced sealing technology, the machine effectively curbs dust spillage and noise pollution, creating a fresh and quiet working environment. At the same time, its excellent crushing efficiency directly reduces the energy consumption level, bringing users significant energy savings and reduced operating costs, and setting a new benchmark for green energy saving in the industry.

Intelligent control of the future

Entering the new era of Industry 4.0, the 9100SE VSI Crusher keeps up with the trend of intelligence and is equipped with an advanced intelligent control system. The system can accurately perceive the real-time operating status and crushing results of the equipment, and automatically adjust the working parameters based on big data analysis to achieve intelligent management and optimization of the equipment. This innovative design not only simplifies the operating process, but also improves the stability and reliability of the equipment, ensures the continuity and efficiency of the production process, and leads the intelligent transformation of the crushing industry.

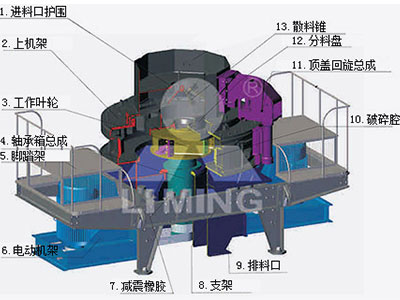

VSI Crusher for sale VSI-9100SE Working Principle

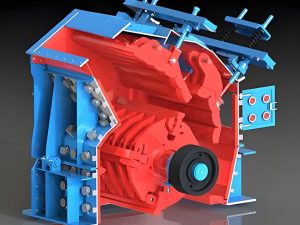

The working principle of 9100SE VSI Crusher is a subtle combination of physical impact and shearing and grinding to achieve efficient crushing of materials. Its core structure includes a powerful rotor, a precisely guided feed inlet, a well-distributed distributor, an impact zone for efficient crushing, a discharge port for smooth material discharge, and a series of carefully selected wear-resistant components. During operation, the motor provides continuous and high-speed rotational power to the rotor, driving the entire crushing process like the heart driving blood.

The material enters the crusher gracefully from the feed inlet and is then scientifically dispersed around the rotor by the distributor to ensure that every particle of material has an equal chance of being crushed. Then, the rotor acts as a precision accelerator, rapidly accelerating the material and throwing it into the core of the impact zone. Here, the material collides violently with the carefully arranged wear-resistant parts on the rotor surface (made of top-grade wear-resistant materials such as tungsten carbide or high-chromium cast iron). Each impact is a powerful challenge to the strength of the material, causing it to gradually disintegrate into smaller particles.

However, the mystery of crushing is far more than that. In addition to direct impact, the material will also experience a feast of shearing and grinding woven by the rotor and the impact plate in the crushing chamber. This composite crushing mechanism, like the patience and strength of water dripping through a stone in nature, ensures that even the hardest or most complex materials can be finely crushed to an ideal state.

Finally, after this series of carefully designed crushing processes, the material elegantly exits through the discharge port with a brand new look. In this process, the addition of a grading device is the icing on the cake. It is like a strict quality inspector, carefully screening and grading the crushed materials to ensure that each product can meet the user's strict requirements for particle size.

VSI Crusher for sale VSI-9100SE Technical Parameters

| Rotor Dia. (mm) | 900 | Operational weight | 14 400 kg (31 700 lbs) |

| Power | 320 - 600 kW (400 - 800 hp) | Maximum feed size | 50 mm (2”) |

| Speed | 1 000 - 1 800 rpm | Minimum capacity | 236 Mtph (289 Stph) |

| Maximum capacity with cascade | 775 Mtph (852 Stph) | Rotor Speed (m/sec) | 80-90 |

| Rotor (rpm) | 1000-1800 | Driving Method | V-BELT |