What is the hourly output of HP400 cone crusher?

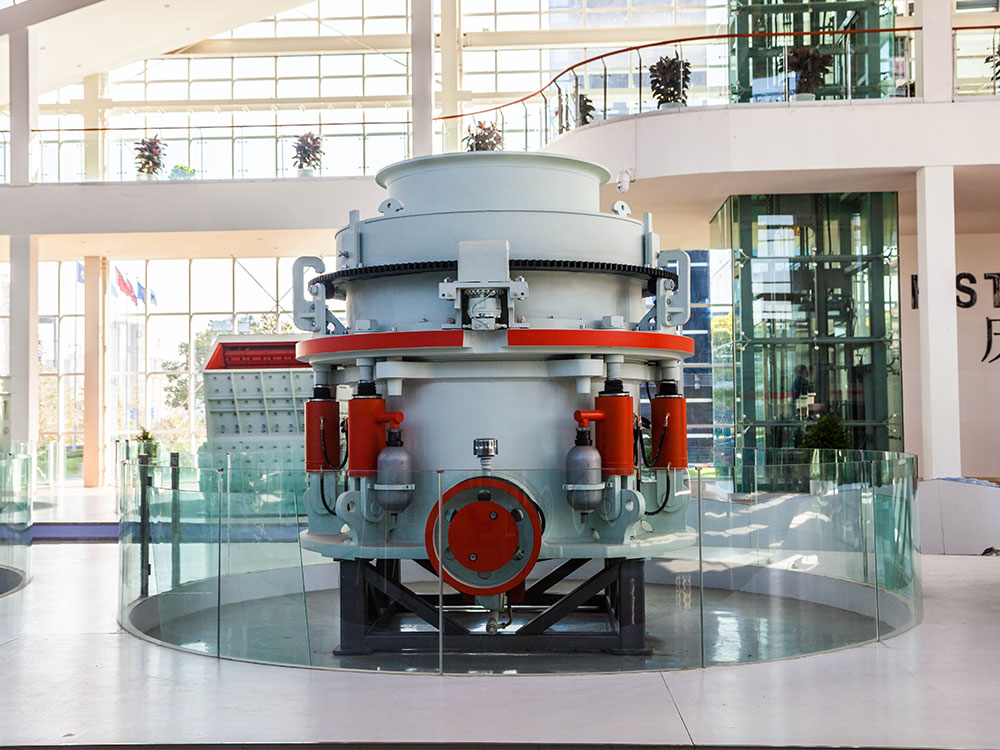

HP400 cone crusher is a high-performance crushing equipment, which is widely used in mining, construction, sandstone and metallurgy industries with its excellent design and stable operation. The equipment adopts advanced hydraulic technology, has high crushing force and excellent processing capacity, and is especially suitable for medium and fine crushing operations, and can easily handle high-hardness and highly abrasive materials. Its design optimizes the shape of the crushing chamber and accessories, so that the material can obtain a more uniform particle shape during the crushing process, and the product quality is greatly improved. HP400 is equipped with an intelligent control system that can monitor the operating status in real time to ensure efficient operation and reduce downtime. In addition, the hydraulic cavity clearing function enables the equipment to quickly clear blockages when encountering overload or foreign objects, reducing damage to the equipment. The equipment also focuses on easy maintenance. The wearing parts are made of high-strength wear-resistant materials, with a long service life and simple and convenient maintenance. In general, HP400 cone crusher is an ideal choice for modern crushing operations with its high efficiency, stability and durability, providing users with high efficiency and reliable performance.

HP400 Cone Crusher Advantages

High-efficiency crushing capacity

The HP400 cone crusher adopts an optimized crushing chamber and a high-efficiency speed combination to achieve higher production efficiency. Especially when processing medium and high hardness materials, its crushing force is particularly outstanding, and large-scale processing can be completed in a short time, improving operation efficiency and saving production costs for users.

Excellent finished product particle shape

The special cavity design of the equipment makes the material evenly squeezed and sheared during the crushing process, ensuring that the finished product particle shape is more three-dimensional and uniform, meeting the market demand for high-quality sand and gravel aggregates. Whether it is construction sand or concrete aggregate, it can meet strict standards.

Intelligent control and high reliability

The HP400 cone crusher is equipped with an advanced automatic control system that can monitor the equipment operation status in real time and optimize parameter settings. The intelligent alarm function can detect potential faults in advance and avoid unexpected shutdowns. At the same time, the equipment structure is sturdy and durable, and the key components are made of high-strength materials to ensure long-term stable operation.

Convenient maintenance and operation

The hydraulic adjustment and cavity clearing functions of the equipment greatly simplify the operation process. When encountering overload or foreign matter entering, the hydraulic system can quickly eliminate blockage and resume normal operation. The wearing parts are easy to replace and have a long service life, which greatly reduces the maintenance cost and workload, and provides users with a more convenient maintenance experience.

Energy-saving and environmentally friendly design

The HP400 cone crusher adopts an energy-saving design, optimizes the power transmission system, reduces energy consumption while still providing powerful crushing capacity. In addition, the equipment has low noise and less dust during operation, meets modern environmental protection production standards, and provides reliable support for green mine construction.

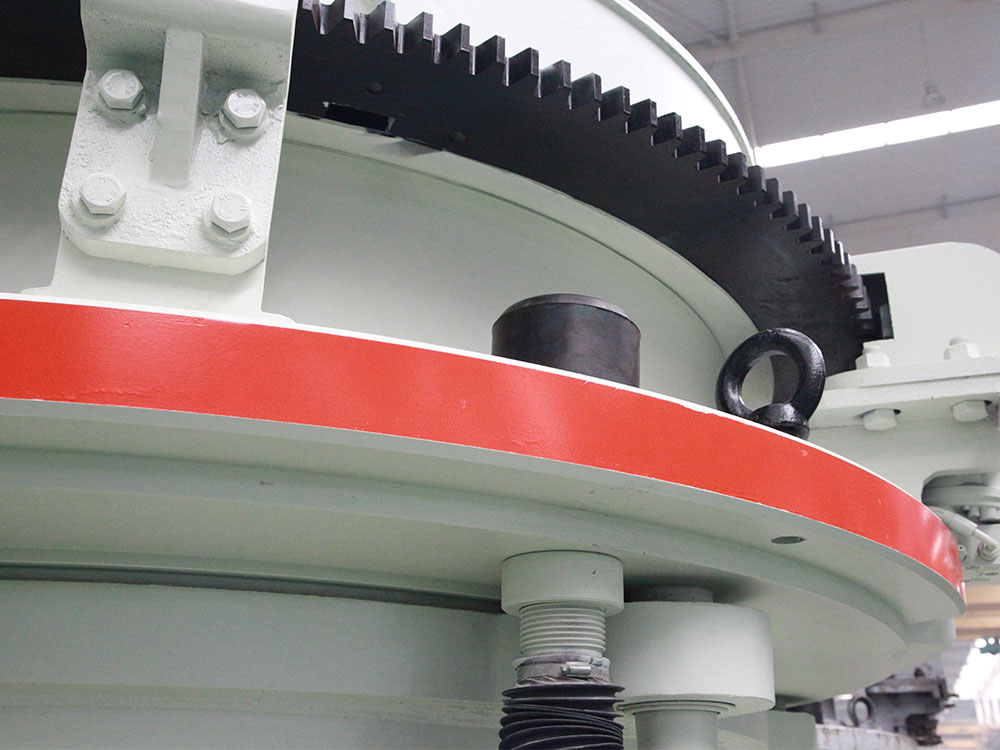

HP400 Cone Crusher Working principle

The working principle of HP400 cone crusher is based on laminated crushing and multi-point contact design, achieving high-quality crushing through optimized cavity shape and efficient rotation speed. Its core components include a movable cone, a fixed cone, a spindle, an eccentric sleeve and a hydraulic system. The material completes the crushing process under the synergy of these components. When the equipment is started, the motor drives the eccentric sleeve to rotate through the transmission device, causing the moving cone to move eccentrically around the main shaft. The crushing cavity formed between the movable cone and the fixed cone is the main area for crushing materials. After the material is fed from the top, it enters the crushing cavity under the action of gravity and is gradually broken into small particles by the multiple effects of extrusion, shearing and bending forces between the movable cone and the fixed cone. As the moving cone rotates, the material in the crushing cavity is continuously compressed and loosened, causing the material to be broken in layers between multiple pressure points, thereby significantly improving the crushing efficiency and improving the product particle shape. The finished material is discharged through the bottom discharge port, and the particle size is controlled by the discharge gap of the equipment. At the same time, HP400 is equipped with a hydraulic cavity cleaning system. When overloaded or foreign matter enters the crushing chamber, the hydraulic system can quickly clear the blockage and resume normal operation. This efficient and reliable design not only protects the equipment, but also improves the continuity and safety of operations. HP400 cone crusher achieves efficient operation through scientific crushing principles, provides users with stable and energy-saving crushing solutions, and is widely used in various ore and sand processing fields.

HP400 Cone Crusher Technical parameters

| Output | 140-630t/h | Feed port size | 295mm |

| Feed size | ≤295mm | Motor power | 315kW |

| Discharge size | 6-51mm | Machine weight | 26t |

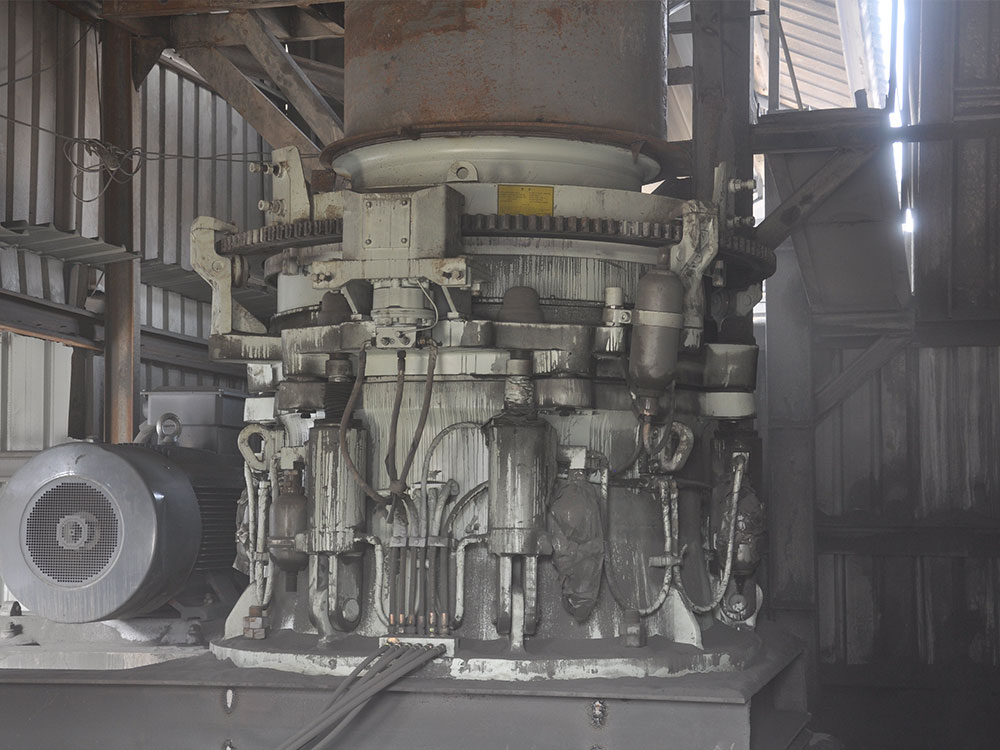

HP400 Cone Crusher Cases and Customer Reviews

Project Background

Mongolia is rich in mineral resources, especially copper and iron ore reserves. In order to meet the high-efficiency needs of ore mining and processing, local companies chose HP400 cone crusher as the main medium and fine crushing equipment for ore crushing production line to help improve mining efficiency.

Case Details

The core equipment of the project production line is HP400 cone crusher, which is matched with auxiliary equipment such as jaw crusher, vibrating screen, conveyor, etc. to form a complete crushing system. The processing capacity is about 500 tons per hour, and the crushed ore has uniform particle size, which is suitable for mineral processing and further processing. HP400 cone crusher adopts laminated crushing technology to effectively improve the product particle shape, and the copper ore and iron ore produced have uniform particle size and high crushing efficiency.

Customer reviews

"I am impressed by the intelligent control system of the equipment. The real-time monitoring function is very practical. It not only allows you to understand the operating status of the equipment at any time, but also quickly gives warnings when abnormalities occur, which greatly reduces downtime and maintenance costs."

"It is worth mentioning that the durability and easy maintenance of this equipment save me a lot of worry. The hydraulic cavity cleaning function solves the problem of crushing cavity blockage, and the replacement of wear-resistant parts is also very simple, making daily maintenance work very easy."