What kind of materials is the 2412 jaw crusher suitable for?

The 2412 jaw crusher is a small and efficient crushing equipment designed for processing small and medium-sized materials, such as ore, limestone, construction waste, etc. It has a compact structure and is easy to operate and maintain. It is widely used in laboratories, small mines, stone factories and construction waste treatment sites, especially suitable for primary crushing of materials. The feed port size of the equipment is 240mm×120mm, which is suitable for processing materials with a particle size not exceeding 100-120mm. By adjusting the discharge port, the discharge particle size can be controlled within the range of 10-40mm to meet a variety of production needs. Its processing capacity is usually between 1-5 tons per hour, and the specific output will vary depending on the hardness, humidity and discharge requirements of the material. The 2412 jaw crusher is made of high-strength materials, with a sturdy and durable structure and stable and reliable operation. The equipment is equipped with a 5.5-7.5kW motor with low power consumption and high working efficiency, which can reduce energy consumption and production costs while ensuring performance. In addition, it weighs about 700-900kg, occupies a small area, is easy to install and move, and is very suitable for users with limited space. In general, the 2412 jaw crusher has become an ideal choice for users' crushing needs due to its high efficiency, energy saving and easy operation. It is widely used in mining, building materials processing and other fields.

2412 jaw crusher Advantages

Simple structure and convenient operation

The 2412 jaw crusher has a compact design, simple overall structure, and is easy to operate and maintain. The equipment is small in size and occupies a small area, which is particularly suitable for small mines and laboratories with limited space. The adjustment function of the discharge port allows users to quickly adjust the material particle size to meet a variety of production needs.

Efficient energy saving and low operating cost

The equipment is equipped with a 5.5-7.5kW motor, which has low energy consumption while maintaining efficient crushing performance, helping to reduce production costs. In addition, the wear-resistant parts of the equipment have a long life and low maintenance frequency, which further reduces maintenance costs and downtime.

Wide range of application and strong flexibility

The machine can handle a variety of medium-hard materials, including ore, limestone, construction waste, etc., and has a variety of application scenarios. Whether in mining, small stone factories, or construction waste treatment, it can efficiently complete the material crushing task to meet the needs of different users.

Adjustable discharge particle size and flexible production

By adjusting the size of the discharge port of the equipment, users can control the discharge particle size within the range of 10-40mm. This flexibility makes it suitable for a variety of crushing processes, from coarse crushing to fine crushing, greatly improving the adaptability and efficiency of the production line.

The equipment is sturdy and durable with a long service life

The 2412 jaw crusher is made of high-strength steel and high-quality wear-resistant materials, and can withstand high-intensity operating loads. Its structure is stable and has excellent impact resistance. It still performs well under complex working conditions, ensuring long-term stable operation of the equipment and creating higher economic benefits for users.

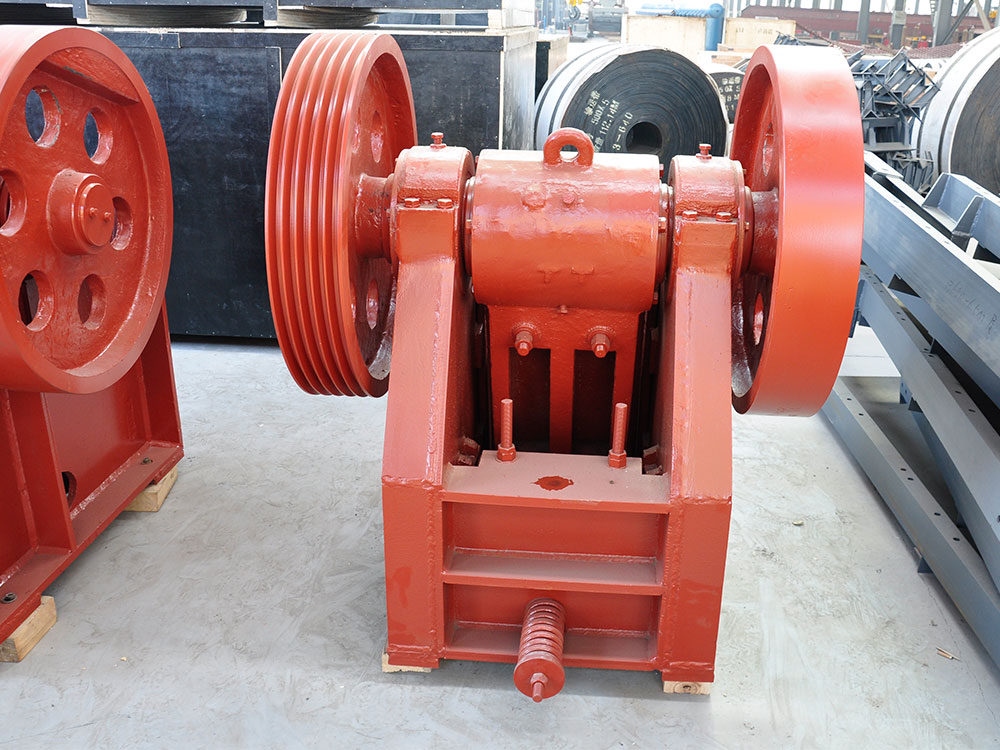

2412 jaw crusher Working Principle

The material to be crushed enters the crushing chamber from the feed port at the top of the equipment. The crushing chamber consists of a fixed jaw plate and a movable jaw plate, presenting a V-shaped structure, which provides sufficient crushing space for the material. The motor drives the eccentric shaft to rotate through the pulley, so that the movable jaw plate swings periodically around the fixed shaft. When the movable jaw approaches the fixed jaw, the space of the crushing chamber becomes smaller, exerting extrusion force on the material and crushing the material into smaller particles. When the movable jaw moves away from the fixed jaw, the space of the crushing chamber increases, and the crushed material is discharged from the discharge port under the action of its own gravity and the operating force of the crusher. By adjusting the size of the discharge port, the final particle size of the material can be controlled. The approach and distance action of the movable jaw continues at a fixed rhythm, and the material continuously enters the crushing chamber to be crushed and discharged, realizing continuous crushing operation. In summary, the 2412 jaw crusher drives the reciprocating swing of the movable jaw plate through the eccentric shaft, squeezes and crushes the material between the fixed jaw and the movable jaw, and discharges it through the discharge port to complete the entire crushing process.

2412 jaw crusher Technical parameters

| Output | 1-5t/h | Discharge size | 10-40mm |

| Feed port size | 240mm×120mm | Motor power | 5.5-7.5kW |

| Feed particle size | 100-120mm | Weight | 700-900kg |

2412 jaw crusher Cases and Customer Reviews

Equipment Selection

Due to the moderate hardness of limestone and the small crushing demand, the 2412 jaw crusher is an ideal choice. The compact design and stable performance of the equipment meet the company's space constraints and medium-scale production needs.

Production process

Feeding: The particle size of the limestone raw material is 80-100mm, which fully meets the maximum feed particle size range of the equipment.

Discharging: By adjusting the discharge port, the limestone is crushed into 20-30mm aggregates for concrete production lines.

Processing capacity: Running 8 hours a day, the average daily processing capacity of a single machine is about 30-40 tons.

Project benefits

Cost control: The equipment operates reliably, does not require frequent replacement of parts, and reduces maintenance and downtime costs.

Product quality: The discharge particle size is uniform, and the specifications of the limestone particles fully meet the standards of concrete aggregates.

Flexibility: Due to the adjustability of the equipment, the company plans to adjust the discharge particle size in the future for more uses, such as road base materials.

Customer reviews

"The performance of the equipment is excellent. We mainly use it to crush limestone. The feed particle size is about 100mm and the discharge requirement is 20-30mm. This crusher can easily reach the target particle size and the discharge is very uniform. It runs 8 hours a day and the output is stable, which fully meets our expectations."

"Most importantly, the equipment is very energy-efficient. The motor power is moderate and the energy consumption is low, which saves a lot of energy costs compared with similar equipment. In addition, its noise control is also very good, which not only meets environmental protection requirements, but also provides a better working environment for our workers"