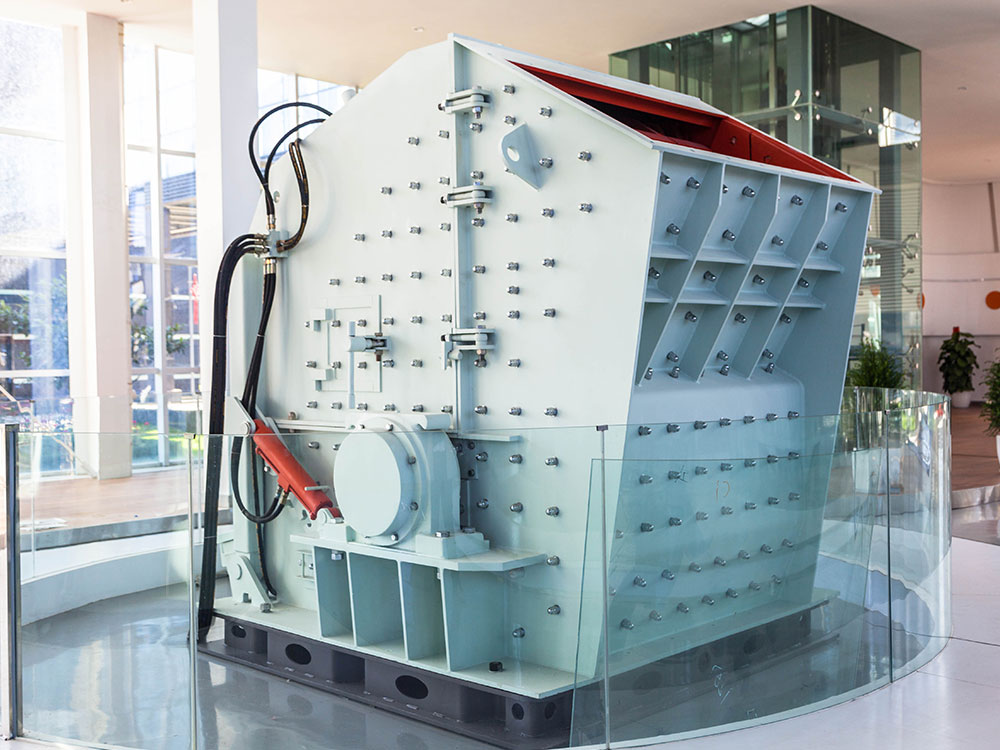

Why choose CI711 impact crusher for crushing operation

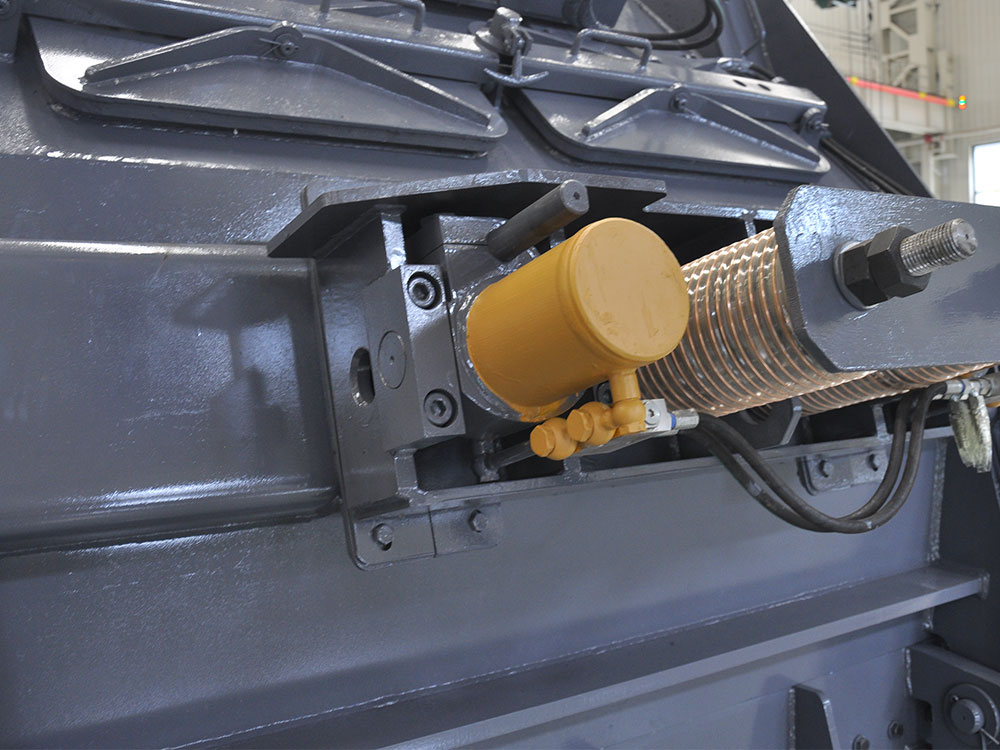

The CI711 Impact Crusher has an excellent crushing ratio and can quickly crush large materials to the required size. During the crushing process, its energy consumption is low, which helps enterprises to reduce production costs. The equipment has a built-in overload protection device, which can effectively avoid equipment damage caused by oversize material or overload. The equipment adopts horizontal shaft design, compact structure and small footprint. The impact block, liner plate, plate hammer and other wear parts are made of high wear-resistant materials, which prolongs the service life of the equipment. In addition, the gap of the impact plate and the opening and closing of the casing can be conveniently adjusted through the hydraulic system, simplifying the maintenance process. The CI711 Impact Crusher is easy to operate, and only requires operators to familiarise themselves with the basic operating procedures and safety regulations to carry out crushing operations efficiently. maintenance of the CI711 Impact Crusher is relatively simple, with regular inspections and the replacement or repair of wearing parts to ensure the normal operation of the equipment, and keeping the crushing chamber clean is also the key to maintenance work. With high crushing performance, compact structure design, easy operation and maintenance, and reasonable technical parameters, the CI711 impact crusher plays an important role in many industries, such as mining, aggregates, construction and so on.

CI711 impact crusher Applications

In the mining process, CI711 impact crusher plays a crucial role. It can quickly crush the mined ore into smaller particle size, which is convenient for the subsequent beneficiation, smelting and other processes. Whether it is limestone and dolomite with low hardness or basalt and granite with high hardness, CI711 impact crusher can achieve efficient and stable crushing operation with its powerful crushing capacity and the application of wear-resistant materials. In addition, CI711 impact crusher also performs well in slag recycling, contributing to the sustainable development of mines.

The CI711 impact crusher also has a wide range of applications in the building materials and concrete industry. It is capable of handling materials of various hardnesses, such as river pebbles and construction waste, and crushing them into the required size for the production of recycled aggregates, mechanism sand and other construction materials. This not only realises the recycling of resources, but also reduces the production cost and improves the economic benefits. At the same time, CI711 Impact Crusher produces less dust during the crushing process, which meets the requirements of environmental protection and provides strong support for the development of green building materials.

CI711 impact crusher also plays an important role in the construction of roads, railways and other infrastructure. It is able to crush large stone materials into the required particle size, providing high-quality filler for roadbed filling. This not only improves the stability and bearing capacity of the roadbed, but also reduces the construction difficulty and cost. In addition, during the maintenance of highways and railways, the CI711 impact crusher can also be used to crush waste pavement materials and achieve the reuse of resources.

In water conservancy, chemical industry and other industries, CI711 impact crusher also has a wide range of applications. It is capable of handling materials of various hardnesses, providing the required raw materials and fillers for production. Meanwhile, with the improvement of environmental protection consciousness, CI711 impact crusher produces less noise and dust during the crushing process, which meets the environmental protection requirements and provides a strong guarantee for green production. In the field of environmental protection, CI711 impact crusher can also be used to deal with all kinds of waste and hazardous waste, to achieve the harmlessness and reduction of resources.

CI711 impact crusher Advantages

Large crushing ratio, simplify the production process

CI711 impact crusher has significant advantages in crushing ratio, which is generally up to 30~40, and even up to 150. This means that a process that originally requires three stages of crushing may be completed with only one or two stages using the CI711 impact crusher, thus greatly simplifying the production process and saving investment and time costs. This highly efficient crushing capacity makes the CI711 Impact Crusher particularly good at handling large materials.

High crushing efficiency and energy saving

CI711 Impact Crusher adopts the principle of impact crushing, making use of the characteristic that the impact strength of ore is much smaller than the compressive strength. Through the high-speed rotor driving the plate hammer to impact the material several times, the material will be cracked along the nodal interfaces and the fragile tissues firstly, so as to realise the high efficiency of crushing. This crushing method not only improves the crushing efficiency, but also significantly reduces the power consumption, making the CI711 Impact Crusher more economical and energy-saving in the operation process.

Uniform product size and less over-crushing

Since the CI711 Impact Crusher uses kinetic energy to crush ores, the amount of kinetic energy possessed by each piece of ore is directly proportional to the mass of that piece of ore. Therefore, during the crushing process, the large pieces of ore are crushed to a greater extent, while the small pieces of ore are not crushed under certain conditions, thus ensuring the uniformity of the particle size of the crushed product and reducing the occurrence of over-crushing phenomenon. This feature makes the CI711 Impact Crusher more advantageous in applications that require specific particle size products.

Adaptable to a wide range of applications

The CI711 Impact Crusher is extremely adaptable, capable of handling a wide range of materials with a particle size of up to 500 mm and a compressive strength of up to 360 MPa. Whether it is hard rock such as granite, limestone, or soft rock such as coal, gypsum, etc., CI711 Impact Crusher is able to carry out effective crushing treatment. This makes it widely used in many fields such as mining, construction material production, water conservancy engineering and so on.

Flexible adjustment to meet diversified needs

The gap between the impact plate and the hammer of CI711 Impact Crusher can be easily adjusted to effectively control the granularity of the discharged material. In addition, fine adjustment of the granularity can be achieved by adjusting the speed of the rotor, the clearance of the grinding chamber, etc. This flexible adjustment capability makes the CI711 Impact Crusher a perfect choice for diversified needs. This flexible adjustment capability enables the CI711 Impact Crusher to meet the diverse needs of different users for product size.

Wear-resistant and easy maintenance

The CI711 Impact Crusher is made of high quality materials such as high chrome hammers and wear-resistant impact liners, which are highly wear-resistant and impact-resistant. This enables the equipment to maintain stable performance during operation and reduces downtime for maintenance due to wear and tear. Meanwhile, the CI711 Impact Crusher has a compact structure, strong machine rigidity, and the keyless connection design makes the overhauling process more convenient, economical and reliable.

Environmentally friendly, improving the working environment

The CI711 impact crusher is designed to improve environmental performance. Through the configuration of reasonable sealing devices and dust preventer, silencer and other equipment, effectively reduce the generation of dust and noise. This not only meets the current requirements for environmentally friendly production, but also effectively improves the operating environment and protects the health of operators.

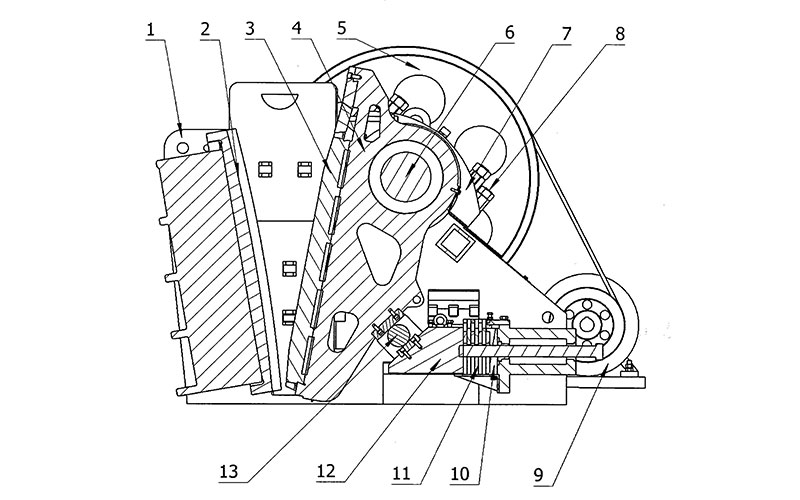

CI711 impact crusher Working Principle

Firstly, the material enters the feed opening of the crusher through the feed opening. Inside the crusher, the high-speed rotor is equipped with several hammer heads or plate hammers. When the material collides with these hammer heads, a high-speed impact force is generated, pushing the material against the crushing chamber wall or other fixed impact plates.

Under the action of impact force, the material is crushed, broken and ruptured. Larger blocks of material will be crushed into smaller particles. Meanwhile, part of the material will repeatedly collide in the crushing chamber and continue to be impacted and crushed until the desired fineness is achieved.

In particular, the CI711 Impact Crusher adopts a horizontal shaft design, and the gap between its impact plate and plate hammer is adjustable in size. This design makes the impact force and the number of collisions to which the material is subjected in the crushing chamber controllable, so that the crushing effect can be adjusted according to the nature of the material and the requirement of particle size.

Finally, the crushed material is discharged through the discharge port, completing the whole crushing process.CI711 Impact Crusher plays an important role in many industries such as mining, aggregate, construction and so on with its high efficiency and stable crushing performance.

CI711 impact crusher Technical Parameters

| Feed size | 600 mm | power | 185 kW |

| Length | 2.84 m | Height | 2.79 m |

| Weight | 11,005 kg | Width | 2.00 m |