Continuous Mine Crushing Mining equipment

BUCKET WhEEL ExCAVATOR - connected to BELTWAGON

a cost-effective link between excavator and conveyor

LIMING specialized equipment for bulk materials handling support continuous mining processes for soft and hard rock.

BUCKET WHEEL EXCAVATORS PE100-PE200 SERIES

LIMING bucket-wheel excavators are designed to strip overburden and mine coal, lignite

and various soft minerals continuously. Controlled by state-of-the art PLC systems with extensive automation possibilities, they have ergonomic, user-friendly interfaces for operator comfort, quick familiarization and sustained high productivity. Since they are of modular construction and custom-built, our bucket wheel excavators are easy to optimize for different applications.

BELTWAGONS PB100-PB300 SERIES

LIMING beltwagons, or mobile transfer conveyors, are designed to form a flexible, adjustable, synchronized bridge between the bucket wheel excavator and the bench conveyor in order to ensure a continuous, uninterrupted flow of material from open pit mining operations.

SPREADERS

PA100-PA300 SERIES

The purpose of the spreader is to receive overburden from the haulage conveyor and dump it in an orderly and efficient manner. The extensive line of LIMING spreaders ranges from

30 m (100 ft) to more than 350 m (1 150 ft) in length corresponding with machine service weights of, respectively, 50 to 4 000 metric tons (55 to 4 410 short tons). Rail or track-mounted tripper cars, usually part of the spreader package and also delivered from LIMING, are used to transfer the material from the haulage conveyor to the spreader.

TRANSPORT CRAWLERS PT SERIES AND AUXILLIARY EQUIPMENT

LIMING transport crawlers are special vehicles used to relocate heavy mine equipment

and plants, such as conveyor drive stations and semi-moble crushing plants safely and economically over rough terrain and/or poor ground conditions. The load carrying capacities of our transport crawlers range from

150 to 1 500 metric tons (165 to 1650 short tons).

FULLY-MOBILE CRUSHING PLANTS PF300 SERIES

The PF300 is a completely new fully-mobile crushing plant with compact design for on-face mining applications which can be equipped with different LIMING crusher types, for

any client’s uniquely varied demands. The stability concept allows loading of the crusher via hydraulic- or rope shovels without any temporary support, keeping the system fully mobile and rock solid under all conditions while machine oscillation is significantly reduced. This not only keeps availability at a high level, but also improves the positioning

of the machine. The PF300 can either work in combination with a beltwagon or loading bridge as the connecting downstream link to the face conveyor, for capacities from 2000 to more than 12 000 metric tons per hour (2200-13 200 short tons per hour).

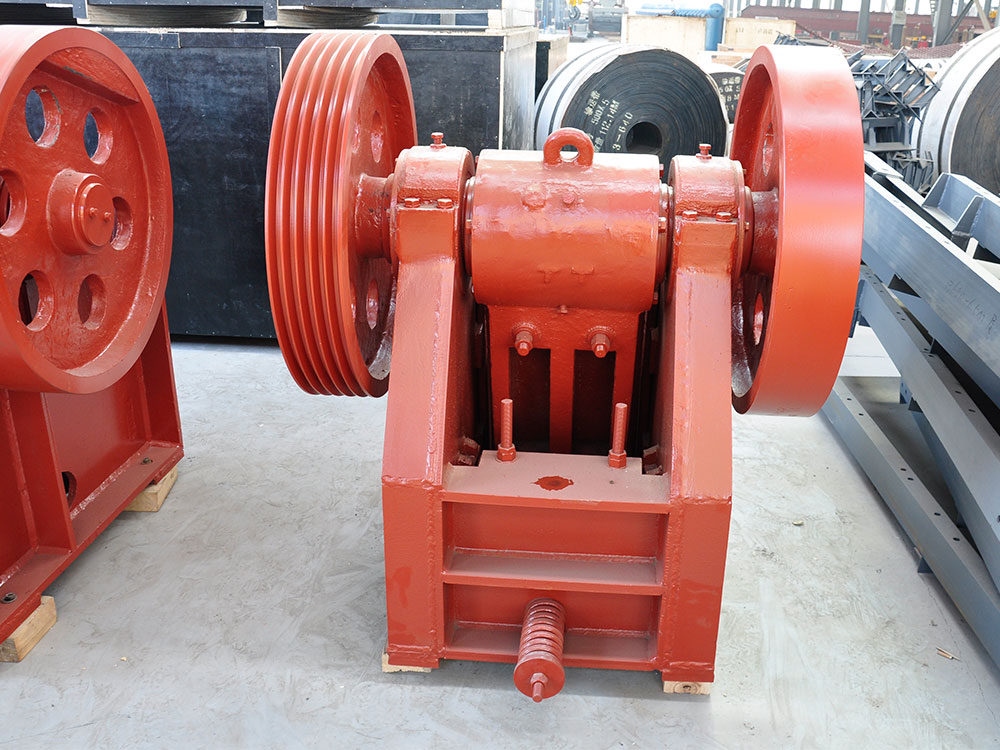

SEMI-MOBILE CRUSHING PLANTS PX100-PX200 SERIES

LIMING semi-mobile crushing plants consist of movable modules and can be shifted to follow the development of the mine site. Crushers represent the core of semi-mobile crushing plants. Depending on the application, various types of crushers can be utilized including the sizer, hybrid, double-roll-, gyratory- or jaw crusher. The throughput capacity can be more than 10 000 metric tons per hour (11 000 short tons per hour), the maximum feed size up to

1500 mm (60 in) and the crushing ratio up to

1:5. Feed materials include coal, ore, limestone, oil sands, gypsum, chalk and similar materials.

STATIONARY CRUSHING PLANTS PZ100-PZ200 SERIES

Stationary processing plants are specially designed for many years of use in one

single, fixed location. To meet the individual requirements for a stationary processing plant, the entire plant is designed and set up in accordance with prevailing local conditions, for throughput capacities of more than

10 000 metric tons per hour (11 000 short tons per hour), usable for coal, overburden, and processing of harder materials such as copper ore and iron ore. Depending on the application, various types of crushers can be utilized including sizer, hybrid, double-roll, primary gyratory- or jaw crusher.