How to maintain the stone sand making machine

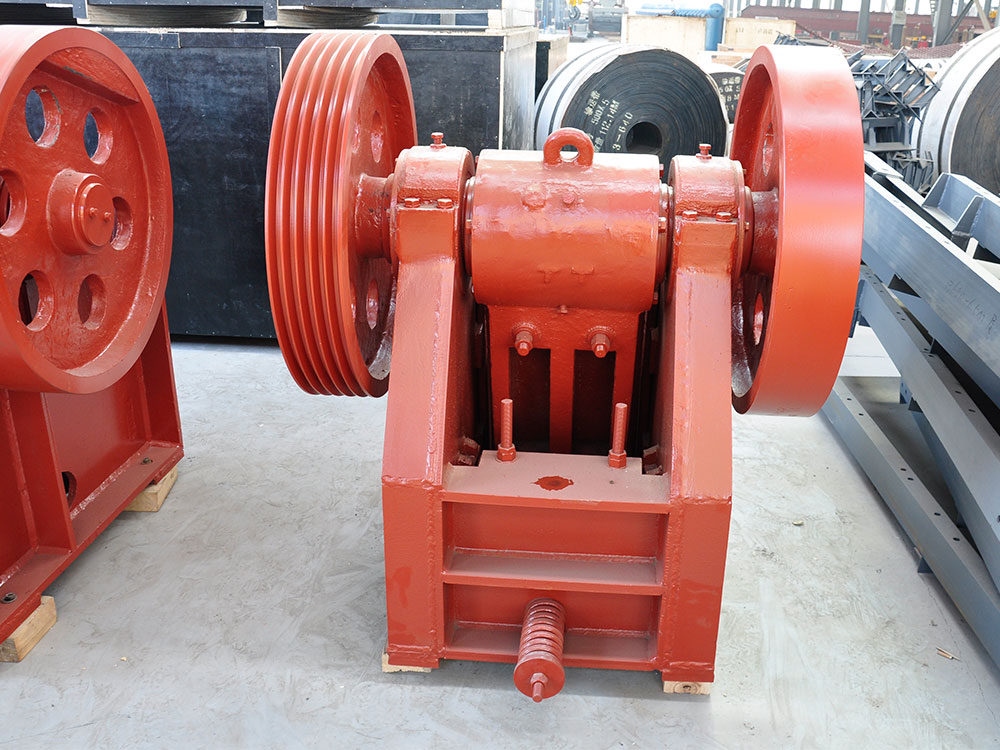

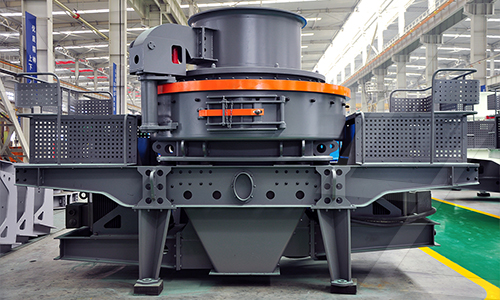

In practice a lot of customers don't know how to maintain the stone sand making machine, here, let me introduce for you. Our stone sand making machine is mainly can be divided into two categories, one is mining system sand machine, is mined ore in mining, need to use when broken flour, workers will need to break out of the ground into pieces of ore into the size, they need at this time often used sand making machine. Another is broken stone sand making machine, the main is some broken rock, rock to produce sandstone, used in the construction industry and the construction of road infrastructure industry, but in addition to the two largest classification, sand making machine in fact can also have more type of segmentation, such as according to its production of materials to split it into the iron sand making machine, sand making machine and so on. We Liming heavy industry mainly produces photo (vertical shaft impact crusher) and new types of 6 x system sand machine, introduce for everybody below system sand machine maintenance and maintenance.

Welcome Advisory Service

Although we use are of high quality steel, and some parts inside the machine all did special treatment. But we still should pay attention to the maintenance of it, this will increase the service life of the machine, reduce operating costs and the risk of out of order.

First stop regularly open the access door look inside the impactor system sand machine wear condition, on the center into the feed tube, cone hat, impeller, the port plate, circular plate, the wear-resisting degree of wear and tear, should be timely replacement or repair, after wear after the replacement of wear resistant block to ensure that each wear-resisting pieces of the same weight. Article 2 sand making machine drive triangle belt tensioning force to adjust the appropriate size, ensure uniform triangle tape bearing, double motor drive, on both sides of the triangle tape should be grouped selection per length to be consistent as far as possible, to make it so that we can make the sand machine equipment more energy efficient production. Article 3 is our company according to the stone sand making machine production time need to do some maintenance, as specified by the machine to 400 hours of work time should be right amount add grease, 2000 hours to work to need to open the spindle assembly for cleaning, to the 7200 hours of work after the new bearing must be replaced. It is strictly prohibited to carry out repairs and maintenance to the machine when the machine is working, make sure after maintenance observe whether the door is on tight vortex chamber, avoid machine after starting materials from observing the door out of danger.

Repair and maintenance of machinery, avoid unnecessary damage. If you want to buy sand making machine, welcomed the advisory service.