Sand making machine parts and its maintenance

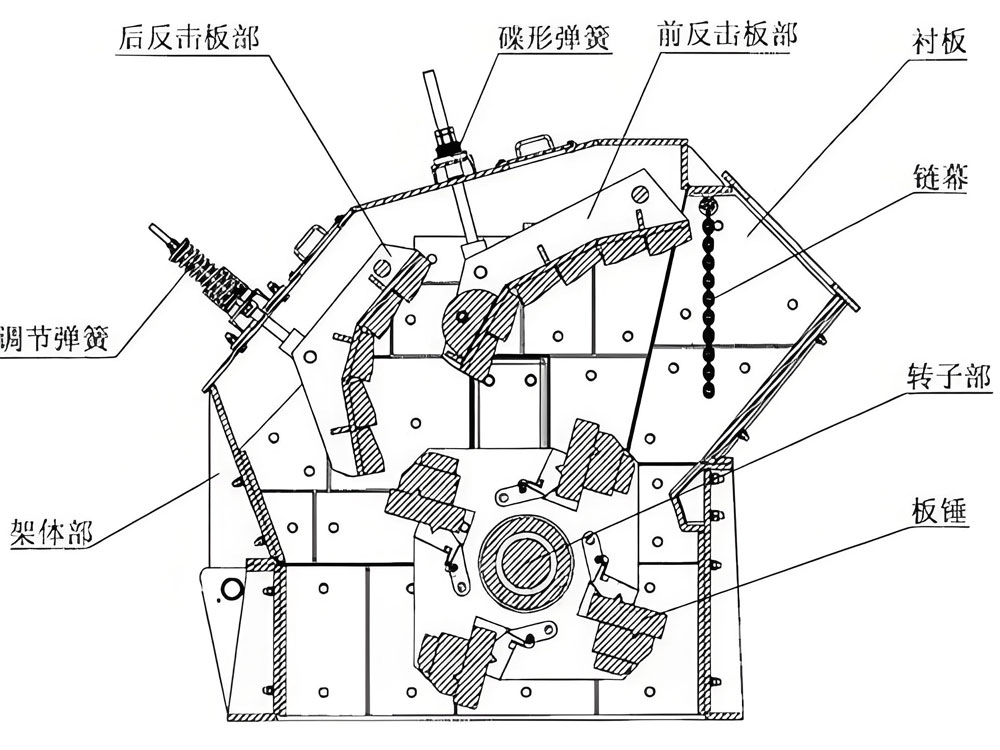

Sand making machine sand is currently on the market of the indispensable equipment, the equipment is made up by many parts, these parts also known as wearing parts, has important role in equipment production, need regular maintenance and replacement. Sand making machine parts usually include plate hammer, side guard plate, back plate, square steel, clamping piece, chassis plate and turn daughter guard board, etc. These parts are used for high manganese steel, high chromium and high fierce composite wear-resistant materials such as forging. Has the advantage of high wear-resistant high impact, improve and alleviate the sand making machine parts often wear problem.

To maximize profits in the production, sand making machine parts, maintenance and maintenance is indispensable to a regular job. Completes the system sand machine parts, maintenance and maintenance work, can reduce the system sand machine failure rate and down time, create more value.

1. The cleaning

Sand making machine because of the work environment, after using a period of time will be affected by the environment pollution, impurities such as dirt, lead to equipment operation is not flexible, wearing parts damage, reduce the production efficiency, therefore, need to clean on a regular basis.

Mining machinery cleaning categorized into acid and alkaline cleaning. Pickling is twenty percent hydrochloric acid solution drip into the dirt, let stand for 10 minutes after rinse, and will constantly stir in water, hydrochloric acid to start the engine, continually swept with a cleaning rod by alkali dissolving dirt, finally rinse off with clear water. Both acid and alkali, the sand making machine and other parts of the cutting tools will have certain corrosive, so the proportion of the solution should be grasped.

2. Maintenance

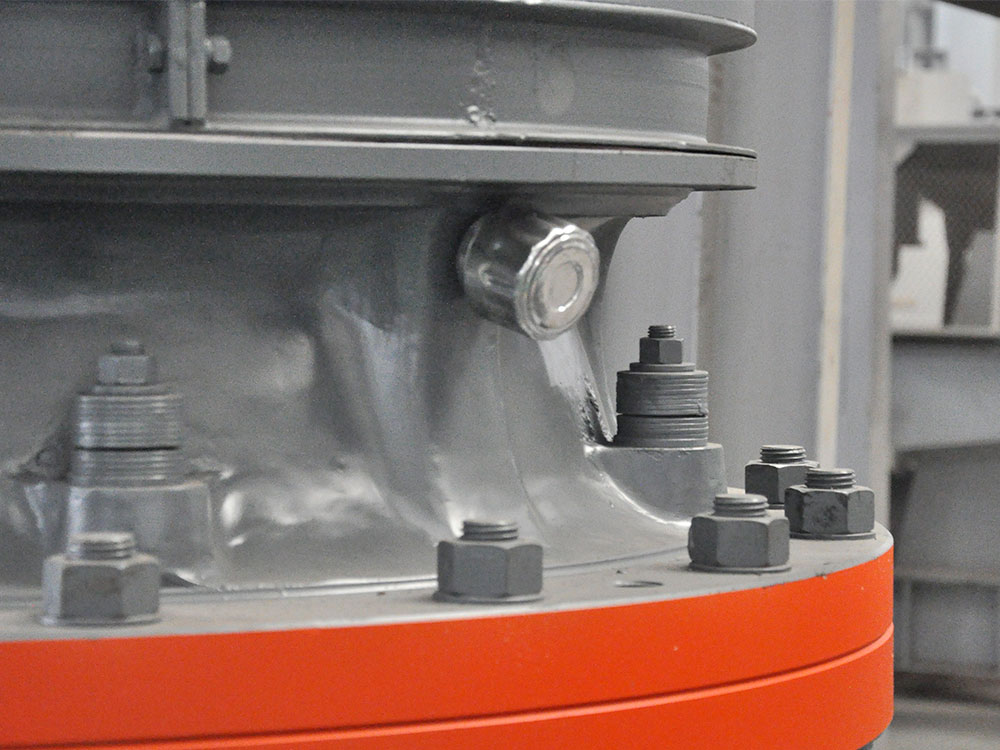

By relaxing the outer ring and increased the maximum stress point, can properly regulate cooperation between various accessories; By changing the wall on both sides of the rotor plate quality in order to improve the balance of the rotor system sand machine precision; Choice has the bearing capacity of strong, self-aligning performance good double row centripetal spherical roller bearings; Between the bearing block and brace in the proper thickness of rubber sheet in order to improve the bearing support flexibility, improve the stress of the bearing, the final purpose of prolonging the service life of the use of parts and equipment.

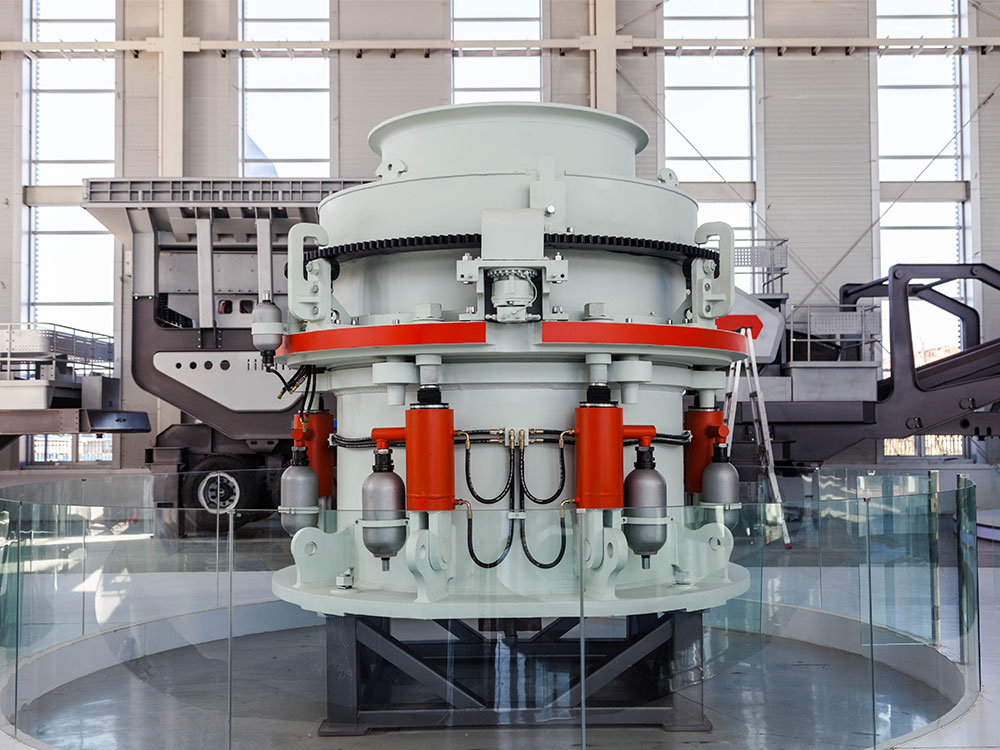

Sand making machine parts

3. Maintenance

Including the sand making machine, sand making machine parts, lubrication, sand making machine belt tension, and so on and so forth. In continuous operation equipment after a period of time, first of all, to regular observation of wear situation of sand making machine parts, including material pipe, plate, round shield block, cone hat, impeller, wear-resisting, etc., and promptly replace or repair. Secondly, the service life of bearing sand making machine is 7200 hours, every work 400 hours, in adding to replace the appropriate grease system sand machine, each work 2000 hours, need to clean the bearing spindle units. Finally, transmission v belt tension size should be adjusted, to ensure that the v belt, double motor drive, to receive strength evenly in the tape, and should be grouped to match the length of triangle sides.

Liming has a variety of types of VSI Crusher, suitable for different materials, access customers consistent high praise, welcome advice website customer service discount.