Cement Ultrafine Mill used in Cement milling process

It is used for the annual output of 300000- 88000 ton and other industry to satisfy different requirement for different customers. Meanwhile, Liming Heavy Industry has the power saving superfine Ultrafine Mill

Cement Ultrafine Mill Main structure and functions:

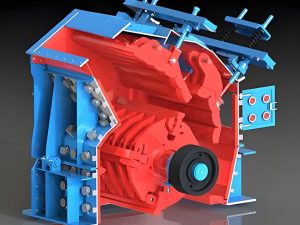

Roller is the main part for grinding the material. There are two rollers in the mill with installed on one axis but moving at different speed. Millstone is fixed on the output shaft of reduction machine, and the material bed is over the millstone with cannelure. PRM Ultrafine Mill is made up of separator, roller, millstone, pressure device, reduction box, electric motor, shell, etc. The separator is the key part that can determine the fineness, which is made up of adjustable transmission device, rotor, fan blade, shell, coarse powder blanking cone measure, air outlet, etc. It has a similar working principle with the powder selector.

Cement Ultrafine Mill Working Principle

The material in flow goes into the separator with the function of counter vanes and rotor, the coarse powder falls from the cone measures into millstone while the fine powder goes out with airflow, then is collected in the dust concentrated equipment and becomes finished product. Simultaneously the material is dried when connecting with air, achieving the required product water content. By adjusting the angle of counter vane leaf and the speed of separator rotor, product of different fineness can be made.

Electric motor drives the millstone via reduction gear. At this time, the hot air enters into the mill from the air intake, and material falls on the center of millstone from the feed opening. Owning to the centrifugal function, material moves to the edge of millstone and is grinded when goes through the circle groove with the function of roller until it is rise by the air but the big sized material will fall back to grind again.

Compared with the ball mill, Ultrafine Mill has its features:

It is obviously that Ultrafine Mill has more advantages than ball mill. To give a direct explaining of MPS Ultrafine Mill’s feature. Take the annual output of 100,000 ton’s sand making machine. Compared with HRM Ultrafine Mill and ball mill of two schemes with index, the index is as follow:

High efficiency of grinding;

Big drying capacity;

Large granularity of material for grinding, secondary crushing can be omitted when using the large and medium size Ultrafine Mill;

More steady of chemical content;

Uniform grading of material and product granularity which is fit for calcine;

Simple process flow;

Low noise and little dust as well as clean operating environment;

Little wear and tear of metal with high-usage;

Economic using;

Suppose the annual output is 100,000 ton cement, to satisfy the production need, two possible ways are adopted:

Way 1: HRM 1300 Ultrafine Mill system

Way 2: 2.2*6.5 meters closed circuit mill system.

Compared with the two ways, the Ultrafine Mill decrease 380,200 RMB per year with immeasurable benefits on engineering level, product’s quality, power saving, operating environment, deducing the noise and waste, improving the adaptation.