Small jaw crusher compound pendulum jaw crusher works

Compound pendulum jaw crusher is one of the medium-grained stone crushing most commonly used crushing equipment. Compound pendulum jaw crusher because of its simple structure, low cost, simple, durable, easy maintenance, etc., most of the production has become most widely used crushing equipment. This crusher can crush all kinds of hardness of ore and rock, mainly for medium-sized mine crushing operations.

Compound pendulum jaw crusher is one of the medium-grained stone crushing most commonly used crushing equipment. Compound pendulum jaw crusher because of its simple structure, low cost, simple, durable, easy maintenance, etc.

Benefits:

Most of the production has become most widely used crushing equipment. This crusher can crush all kinds of hardness of ore and rock, mainly for medium-sized mine crushing operations. Production of PE and PEX jaw crusher is absorbing foreign advanced technology, combined with domestic sand and gravel industry research and development from the specific mining conditions. PE, PEX series compound pendulum jaw crusher is a complex swing crusher equipment for metallurgy, mining, construction, transportation, cement and other sectors, as rough broken, broken compressive strength 350Mpa or less, a diameter of 500 use a variety of ore or rock to 1800mm.

Features:

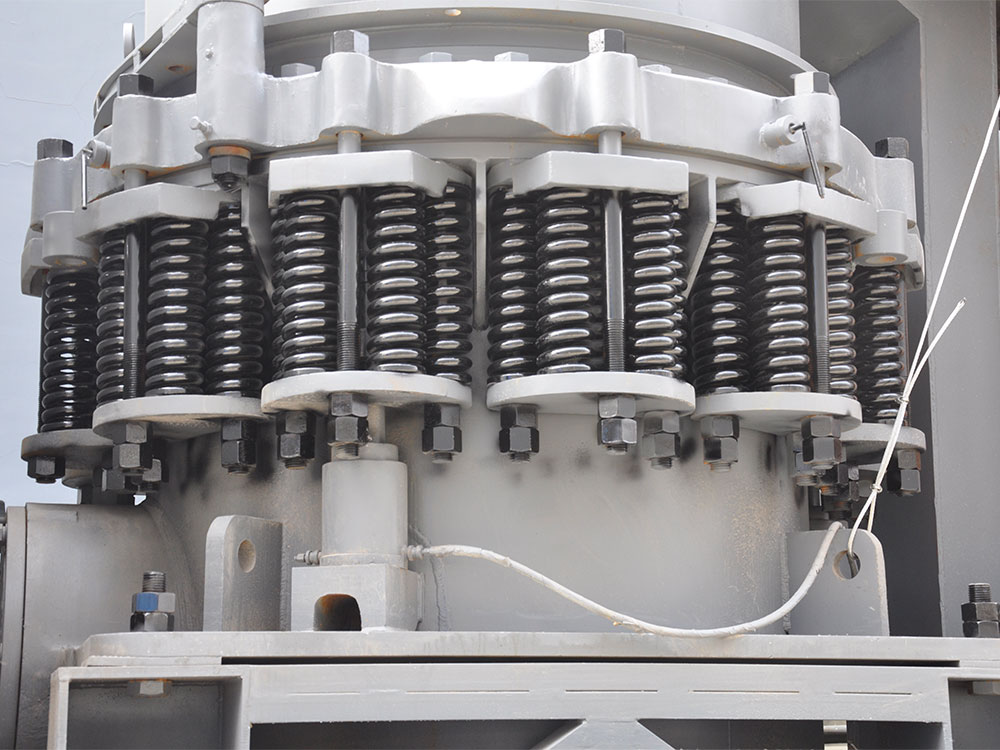

Complex swing jaw crusher mobile jaw plate up and down movement can promote the discharge of the role, and its level is greater than the lower portion of the upper part of the trip, easily broken chunk of material, so the crushing efficiency is higher than the elbows plate. The disadvantage is that the jaws wear faster, and there will be over crushed material leaving the higher energy phenomenon. In order to protect the important components of the machine are not damaged due to overload, often simple shape, smaller size bracket designed for weak links, making it the first deformed or broken when the machine is overloaded. In addition, to meet the different requirements of the nesting size and compensation jaw plate wear, but also created nesting population adjustment device, usually between the elbow board seat and rack and release after adjusting pads or wedge iron. However, in order to avoid the replacement of broken parts and affect production, it may also have hydraulic device to achieve insurance and adjustments. Jaw crusher also directly driven by hydraulic drive movable jaw plate to complete the crushing action of the material.

Complex pendulum jaw crusher and Jane pendulum compared to its advantages are: the quality of light, fewer components, more compact, better crushing cavity full extent of the loaded material block is evenly broken, to the lower end of the movable jaw Mandatory introduction of finished unloading, so the higher productivity than the same specifications of simple pendulum jaw crusher 20-30% higher productivity; material block in the lower portion of the movable jaw has a larger roll up and down movement, easy shape of a cube unloading, reducing the pendulum like Jane sheet products as ingredients, better product quality. It has a simple and reasonable structure, high yield, crushing ratio, long life tooth plate, finished uniform size, low power consumption, easy maintenance, etc., is currently the most advanced models