In the winter, how to care for crushers

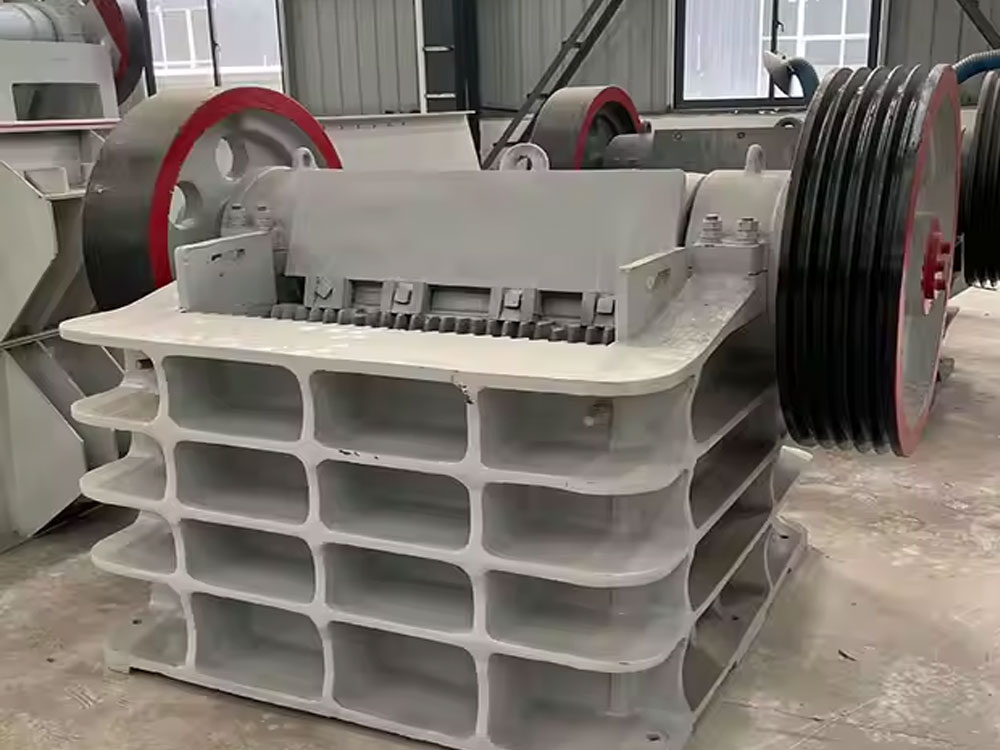

With crusher crusher on the basis of the development of continuous improvement, product performance has also been improved to a greater extent to meet the user's requirements, but also to some extent to improve the overall process of mining. That crusher to improve the process, the high temperature or low it will certainly have some impact on how to solve this problem? Jaw crusher, impact crusher, cone crusher, impact crusher and so on, to make them capable of minus 50 degrees Celsius can still work without load.

As the winter temperature is relatively low, not only greatly reduce the life of the crusher, crusher make it easier for the oil and water is frozen, so in the winter before the best crusher to do a thorough inspection, maintenance, to ensure the project safety of machinery for the winter, to avoid problems when the machine to impact on production. Note that in the winter maintenance of the crusher as follows:

Clean crusher:

Exterior cleaning construction machinery diesel engine, chassis, equipment decontamination cleaning can play a role in the cleaning process can also be found in each device, component damage and oil leakage site, do the preliminary work for the next maintenance. It is forbidden to use high-pressure water gun to flush water temperature demanding parts, especially electrical parts, to avoid damage.

Selection and replacement of oil:

1. Selection of fuel oil. Diesel is easy to wax at low temperatures, the viscosity increases, fluidity, atomization bad, so that the deterioration of the combustion process, reducing engine power and economy. In order to make diesel engine soft, reduce fuel consumption should be used in a low pour point diesel.

2. Replace diesel oil. Diesel should use smaller low viscosity oil. Try to use a high-performance engine oil, such oil is not only easy to oxidation at high temperatures, and will not leave deposits on precision parts diesel engine, can greatly extend the life of diesel engines. Change the oil while the oil filter should be replaced or cleaned.

3. Replace the lubricating oil and grease. When seasonal maintenance, the gear oil transmission, sub-actuators, differential, steering gear inside the gear oil into winter, pay attention to cleaning oil change.

Maintenance parts:

1. Sand production line maintenance and inspection of working conditions thermostat diesel engine cooling system to prevent the diesel engine water temperature is too low or too high. Clear water jacket scale. To select the area below the construction machinery use the lowest temperature around 10 ℃, and with winter frost, summer, anti-boil, anti-corrosion, waterproof scale of long-term antifreeze. Once a tank silt deposition immediately clear.

2. Check the battery maintenance of electrical equipment electrical wiring. Examine and adjust the electrolyte density. Maintenance start the motor, increase the charging voltage generator. Winter should always charge the battery, maintenance preheating device.

3. Note that the brake fluid maintenance braking system adequacy, broken quality is deteriorated. Check the water separator, sewage discharge switch is working properly. Check whether the weak braking, deviation, lack of intensity pedaling brake pedal and the brake does not return the phenomenon, timely adjustment.

The pursuit of excellence and innovation of the Liming team,will continue to use high-quality products, professional skills, sincere services to help customers create more revenue, with practical actions to promote the construction of the world's machinery manufacturing industry. If you want to field trips to our company and production base, You can send mail to tell us your needs or leave your contact information, we will contact you shortly, Liming happy to serve you!