JC Series Jaw Crusher

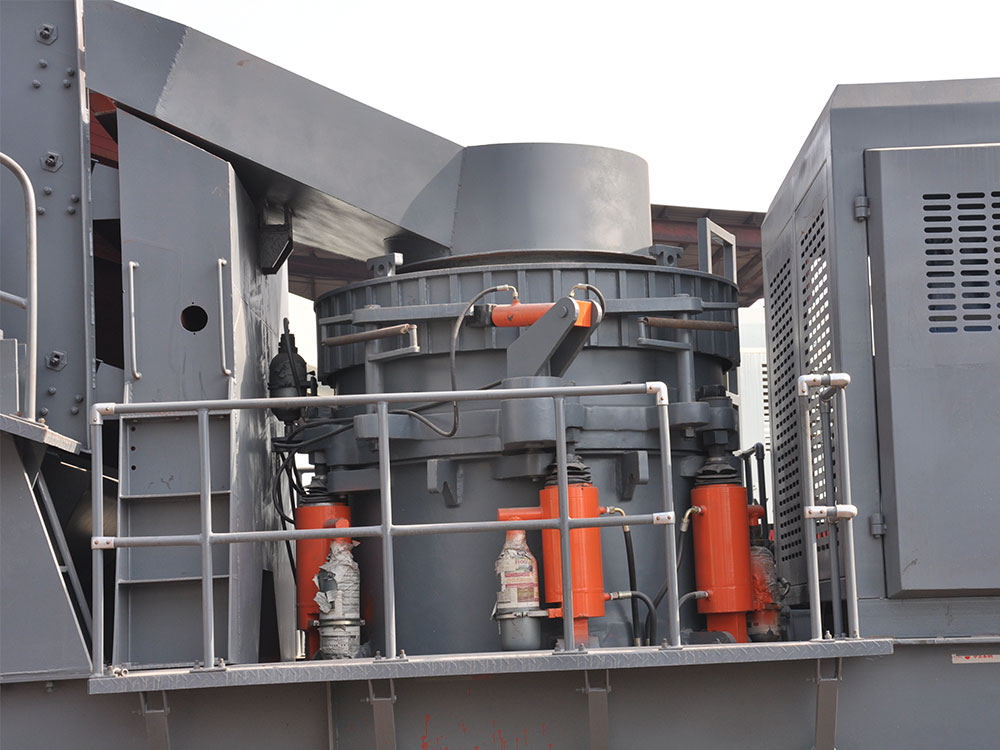

OUTPUT SIZE: 10mm to 275mm

PRODUCTION CAPACITY: Up to 85TPHKEFID is a world-leading company in the field of making rock and mineral processing machine, which has equipped tens and thousands of crushers around the world since the late 20th century. Nowadays, the JC stone jaw crusher in European style undoubtedly becomes the most welcome products in the world. When you want to crush the hard materials in high efficiency, the best choice for you is the JC series of stone jaw crusher in European style, which adopts the most advanced international crushing technology as well as the world-class skills in making.

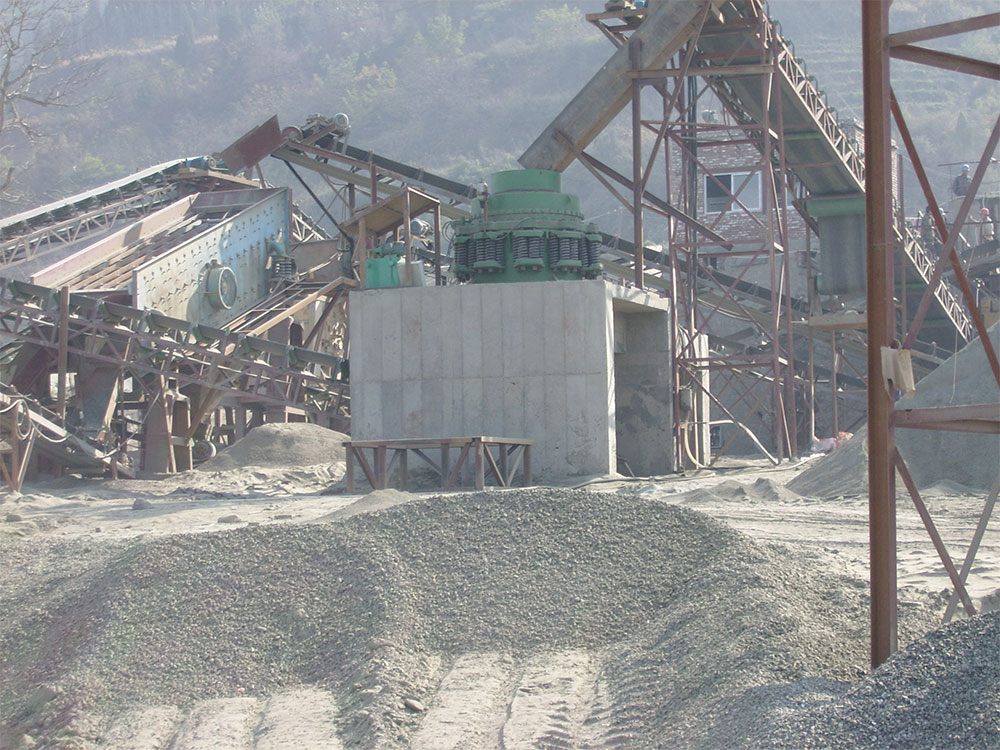

European version of the jaw crusher broken material often used in the mine a break or two broken. European version of the jaw crusher for highways, railways, airport runways and other projects developed by broken stone used in construction of advanced equipment. European version of the jaw crusher crushing using the most advanced technology and manufacturing level, is a multi-hard, strong abrasive materials of choice when crushing efficient products. Most highways, railways, airport runways and other projects based hard rock with a basalt stone, the material hardness specifications about 3--7 cm, and broken relatively large, general jaw broken (broken jaw) not only yields low and easy to wear ʱ?? European version Jaw Crusher compared to the traditional two jaw crusher, for both service life, maintenance rate, failure rate reflects its unparalleled superiority, with respect to supporting the use of cone-breaking, stone shaping machine to that the costs also end.

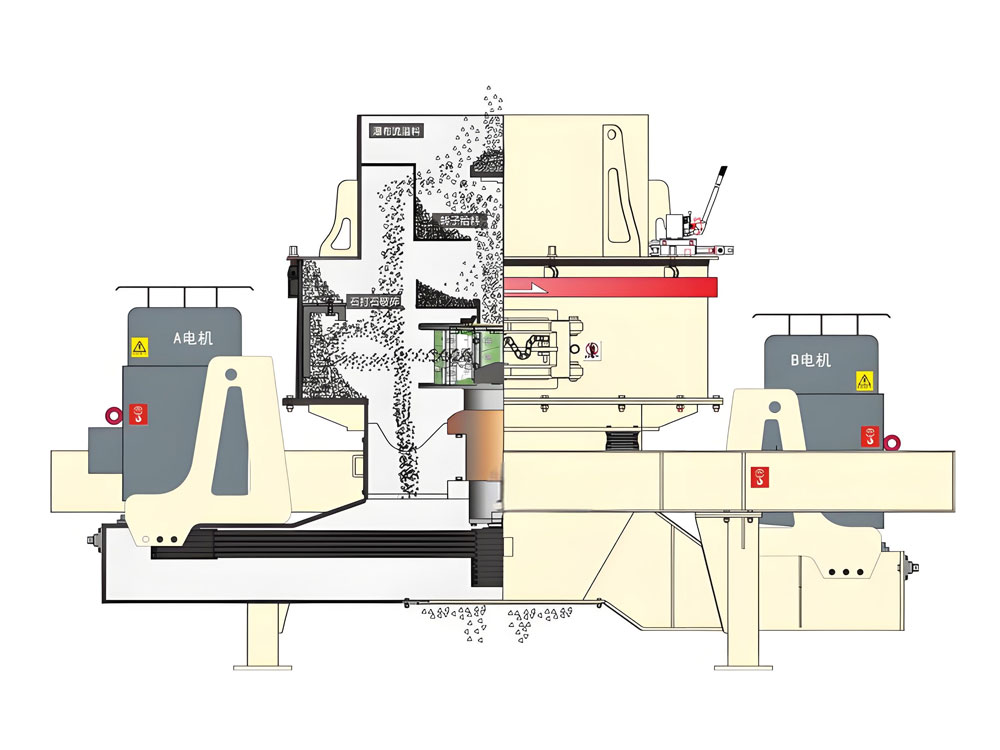

working principle:

European version of the jaw crusher mainly includes base, fixed jaw, jaw, eccentric shaft, set the fixed jaw fixed jaw tooth plate, movable jaw tooth plate by connecting rod bolt fixed to the movable jaw, moving, fixed jaw tooth plate The both sides with side shields, the upper end of the movable jaw suits between the eccentric shaft and the eccentric shaft is provided with movable jaw bearing chamber, which move up to the top jaw tooth plate fixed jaw tooth plate about 80-250mm. Simple and reasonable structure, higher than the fixed jaw tooth plate on fixed jaw and bearing chambers have good protection, and ensuring the material flow, to avoid the plug material card machine phenomenon, safe and reliable, and the utility model also simplifies the moving jaw making, movable jaw bearing chamber sealing, good operating performance, no leakage, improve the machine usage, low noise, smooth operation, saving significant energy savings, which will help promote the application, widely used in mining, building materials, silicate salt fields, metallurgy, road construction, chemical and other industrial raw materials, especially suitable for crushing medium hardness material, such as rocks, minerals, cement clinker, etc.

Kefid JC Jaw crusher is the most common crusher in crushing industry, it is widely used in ores, construction materials, chemistry, metallurgy and so on. Stone and rocks with compressive strength not more than 320Mpa can be experience rough crushing, medium fine crushing and super fine crushing. The european jaw crusher is able to crusher efficiently materials with high hardness and abrasive resistance.

Features of JC Jaw Crusher:

1.The jaw integration is the most advanced one, which makes the machine quite durable.

2. Wiht the limited elements analysing technology, the crusher can gain a higher intensity.

3. Adjustment of the discharge part is more convenient.

The adjustment methods: gasket adjustment, hydraulic assistant adjustment, wedge block and wedge hydraulic adjustment.

4. More advanced movable jaw assembly lengthens life of crusher.

Movable jaw assembly is made from cast piece with high-quality, is driven by two large flying wheels which are made from cast steel. Moreover, heavy eccentric shaft is processed by forged mold. All of these make the JC series jaw crusher extremely reliable.

5. Integral cast steel structure is adopted for bearing seat. Integral cast steel bearing matches well with the crusher frame, at the same time, radial strength of the bearing seat is highly strengthened.

6. Finite element analysis technology is adopted to make the crusher much stronger.

7. Crusher chamber adopts "V" structure which could make actual feed width comply with the nominal one.

8. Bearing with larger model and higher load are used.

All JC jaw crusher is equipped with larger bearing compared with same model of normal jaw crusher. Its higher load capacity and effective oil seal will lengthen the life of bearing.

9. A newly designed tooth-shape side plate, makes the available area of jaw plate longer, and enhances the capacity.

10.Teeth-like protective plate is adopted, which will effectively lengthen the functional length of jaw plate and boost the capacity.

11. Heavy type protecting plate is installed for bearing seat, accidental damage of bearing seat is avoided.

12. Supporting bar under jaw plate protects movable jaw and frame from being worn down. rate bearing seat does not have this advantage. .

SPECIFICATIONS

Mm to inch conversion: 25.4millimeters=1 inch

Note: Any change of European Type Jaw Crusher technical data shall not be advised additionally.