For ball mill’s maintenance is a regular work, it should be closely combined with the mill operation and maintenance. The quality of maintenance work directly affects the operation of the mill and the mill rate life. To shorten the mill downtime, must be checked in time and there are plans to replace the damaged or defective parts. Therefore, the need to develop a maintenance plan, regular and timely manner in accordance with the planned overhaul, to prevent unnecessary delays.

About a month need to overhaul the contents are:

1. The need to check the oil pump, oil filter and so on, you can select the cleaning and replacement of oil;

2. For each part of the device bolts examination, filling and tightening;

3. Check the ball mill big, small transmission gear, recording wear each inspection, replacement and repair of worn pinion gear;

4. Check the couplings and replace the elastic rubber ring and other components;

5. Check and repair the feed tube and a feeding tube;

6. Check the feeder, power systems and ancillary equipment, and so on.

About 4-6 months to check the items except the first one also includes:

1. All small repair projects;

2. Check and replace the feed tube, the feed tube and the feeder;

3. Repair transmission gear.

About 2–4 years needs an overhaul once in addition to the first two also included :

1. Simplified inspection, repair or replacement;

2. The repair and replacement of ball mill feed, the feed cover;

3. Repair Replace the main bearings and gear, and so on.

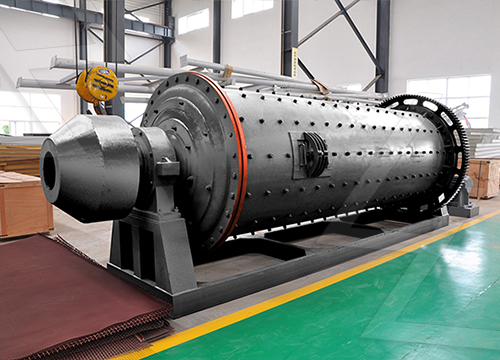

Liming Heavy ball mill have advanced technology, superior quality, choose us is to choose success!