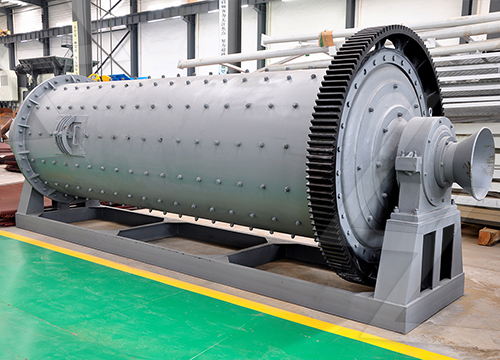

Is now mine choose equipment high-speed development period, the ball mill is no exception. Grinding ball mill is mainly for material, until you reach the qualified size, but in the process of ball mill run, due to various reasons, there will be excessive crush granularity unqualified phenomena appear, in order to prevent the occurrence of this phenomenon, henan Liming at the ball mill at run time to tell you should pay attention to the details:

1. Before loading steel ball, determine appropriate steel ball diameter, the ratio of steel ball.

2. The feed particle size control in ball mill equipment to permit range.

3. Control the motion of grinding medium, to give priority to in order to throw down state.

4. Regular inspection, according to the situation of material after grinding to determine whether to increase the count.

5. Timely ruled out after fine grinding material at the same time, timely added new raw material, make the accumulation of coarse grain materials remain at a high level.

Excessive crush will not only waste a lot of raw materials, but also for personnel as well as the production time is a great waste of henan Liming remind users when running the ball mill equipment, must grasp every detail, to prevent excessive crush phenomenon appeared.

Click for detailed information on Liming ball mill: Ball mill