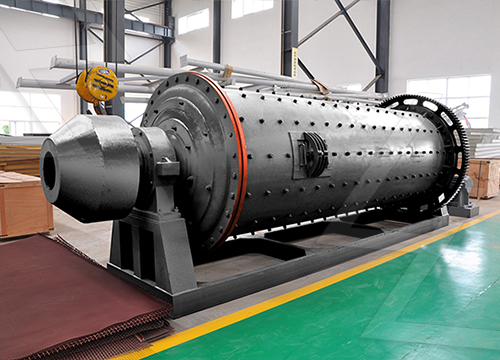

Ball mill is now indispensable equipment in the mineral processing industry, and then when we were in the use of ball mill is always going to have some mechanical failure, in fact, some fault can be avoided, it relies on we are not regular inspection on equipment, ball mill routine inspection should pay attention to what issues?

First, check each part of the device interface between whether there is a screw loose, especially lining board screw loosening, tensile, cause slurry; This work is the best every time succession.

1. Check all the connecting bolts fastening situation of ball mill group, such as found to tighten loose must stop.

2. Check the wear condition of sand return spoon head; Regularly check the liner wear, grinding to a certain degree should be replaced.

3. Pay attention to the discharge grinding machine run coarse or spit balls.

Second ball mill oil supply system inspection work:

1.Always check whether the oil pressure is normal, should maintain in 1.5 ~ 2.0 kg/cm2.

2.Check the oil and the oil temperature, oil temperature shall not exceed 30 ℃.

3.Check the main journal oil flow distribution is uniform.

4.Oil viscosity and cleanliness.

Ball mill motor inspection: the main check the motor temperature, the temperature rise shall not exceed the permitted values.

Finally the ball mill classification equipment inspection work:

1.Check whether spiral classifier leaf falls off, whether smooth rotation.

2.Cyclone feed pressure is stable, if there is a ground leak or blocking phenomenon.