Rubble Recycling Plant for Greater Munich

Plant Description

This crawler-mounted mobile recycling plant is used to process building rubble, concrete and broken asphalt paving to generate a classified high-quality end product. This compact unit accommodates all the necessary processing stages – pre-screening, crushing, control screening and metal separation – characterising the exceptional mobility of the recycling plant on the work site.The plant is fed by hydraulic excavator. By means of a vibrating feeder with variable drive, the raw material is delivered to an eccentric screen which separates the material at 45 mm and 10 mm. The < 10 mm fines are discharged by a separate belt conveyor, and the 10 - 45 mm fraction is re-united with the product flow downstream of the crusher.

The > 45 mm material is selectively crushed in the impactor, in other words, all re-bars and the like are separated from the actual concrete. The impact crusher, which has been specially designed for use in the rugged recycling environment, is equipped with the latest hydraulically- controlled impact apron support and adjustment system, which retains the aprons securely and reliably in their pre-set position. On entry of any problem tramp metal, the impact aprons retract to allow the passage of the tramp metal, automatically returning to their original pre-set position as soon as the hazard has passed. This system ensures a high degree of operational safety and consistent product quality. The material discharge is arranged in the rotational direction of the impactor rotor, giving low trouble operation, even when concrete with a high rebar content is being processed. Ferrous material is eliminated from the product by an over-belt magnet and discharged in the direction of conveying. A downstream control screen separates the small amount of oversize > 56 mm present in the product and which is then stockpiled and returned to the impactor for re-processing as convenient. By means of conveyor belt, the product 0 – 56 mm is conveyed to the product stockpile.

Thanks to the selective crushing coupled with the outstanding technology, the end product is an excellent recycling material which, by reason of its gradation, structure and quality, is a valuable and highly-marketable product.

Technical Data

Feed material: building rubble, concrete and broken asphalt paving

Feed size: 0 – 600 x 500 x 500 mm edge length or

slabs 0 – 1,200 x 1,000 x 250 mm

Capacity: up to 250 t/h according to type of feed material

Pre-screening: eccentric screen, separating at 45 mm and 10 mm

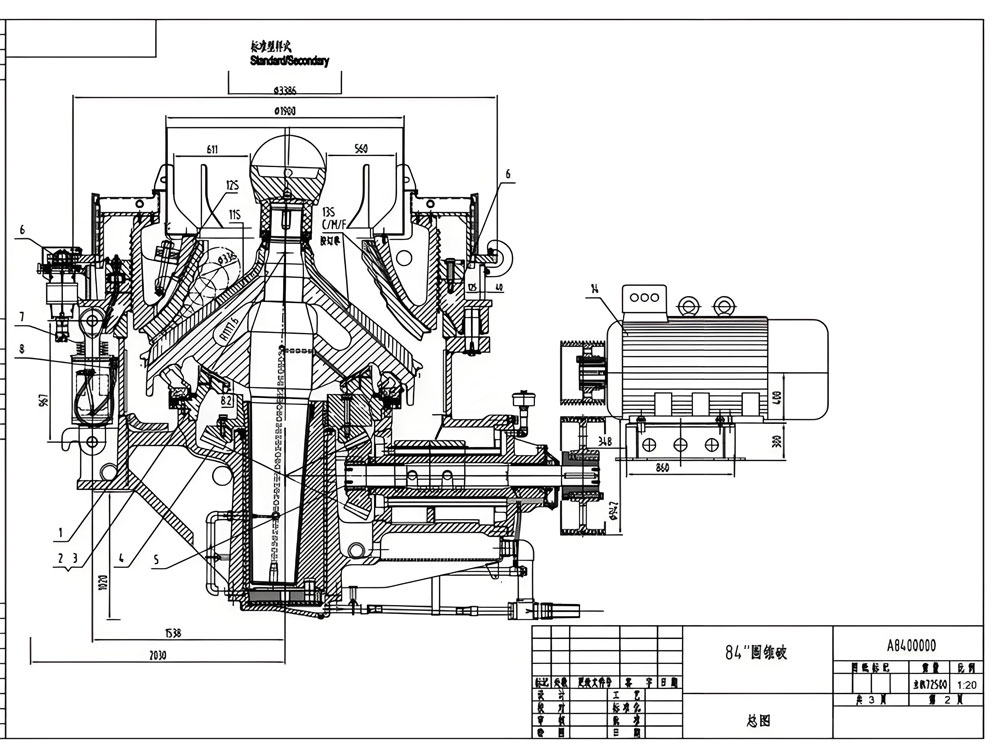

Impact crusher: AP-PH 1214

Inlet: H x W approx. 940 mm x 1,360 mm

Drive rating: 200 kW

Crusher product: 0 - 56 mm or 0 – 32 mm with some 4 – 8 % oversize

Control screen: separation at 56 mm or 32 mm

Installed power: 500 kVA three-phase diesel generator

Total weight of plant: 78 tons