Barmac B5100SE impact crusher accessories and maintenance

The Barmac B5100SE impact crusher is an efficient vertical axis impact crushing equipment widely used in the fields of ore processing, construction sand and gravel, and industrial minerals, especially suitable for producing high-quality fine sand and gravel. As a member of the Barmac series, it adopts a unique "stone to stone" crushing principle, which achieves crushing through self impact between materials, reducing equipment wear and improving service life. In addition, the crusher has significant advantages of low energy consumption and high yield, which can minimize the production of fine powder during the production process, ensuring uniform particle size and stable quality of the finished product. The design of B5100SE impact crusher model focuses on improving crushing efficiency, suitable for small and medium-sized production needs, while maintaining the durability and stability of Barmac equipment. Its compact structure, easy maintenance, and highly modular design allow users to easily replace and maintain major components, thereby reducing downtime and improving production efficiency. In addition, the Barmac B5100SE impact crusher can be adjusted according to user needs to meet the requirements of different material types and finished product specifications. This equipment performs well in terms of environmental protection, producing less dust during the crushing process and meeting modern environmental requirements. It is an ideal choice for producing high-quality sand and gravel materials.

Barmac B5100SE impact crusher accessories and maintenance advantage

Efficient crushing technology

Barmac B5100SE impact crusher adopts the principle of "stone hitting stone" for crushing, and the materials are crushed by mutual impact, reducing direct wear on the crushing chamber. This design not only effectively reduces the wear rate of equipment components, but also ensures high crushing efficiency and good finished particle size, making it suitable for production scenarios that require high-quality sand and gravel.

Stable quality of finished products

This crusher can effectively reduce the generation of excessive fine powder during the crushing process, ensuring uniform particle size and excellent particle shape of the finished product. Its finished product quality meets the high standard application requirements of buildings, roads, etc., making it particularly suitable for production with high demands.

Low energy consumption and high efficiency

Compared with traditional crushers, the Barmac B5100SE impact crusher has lower energy consumption under the same conditions, making it suitable for energy-saving production needs. Through unique crushing principles and optimized design, the equipment consumes less energy during operation, but has higher crushing efficiency, reducing production costs.

Easy maintenance and low operating costs

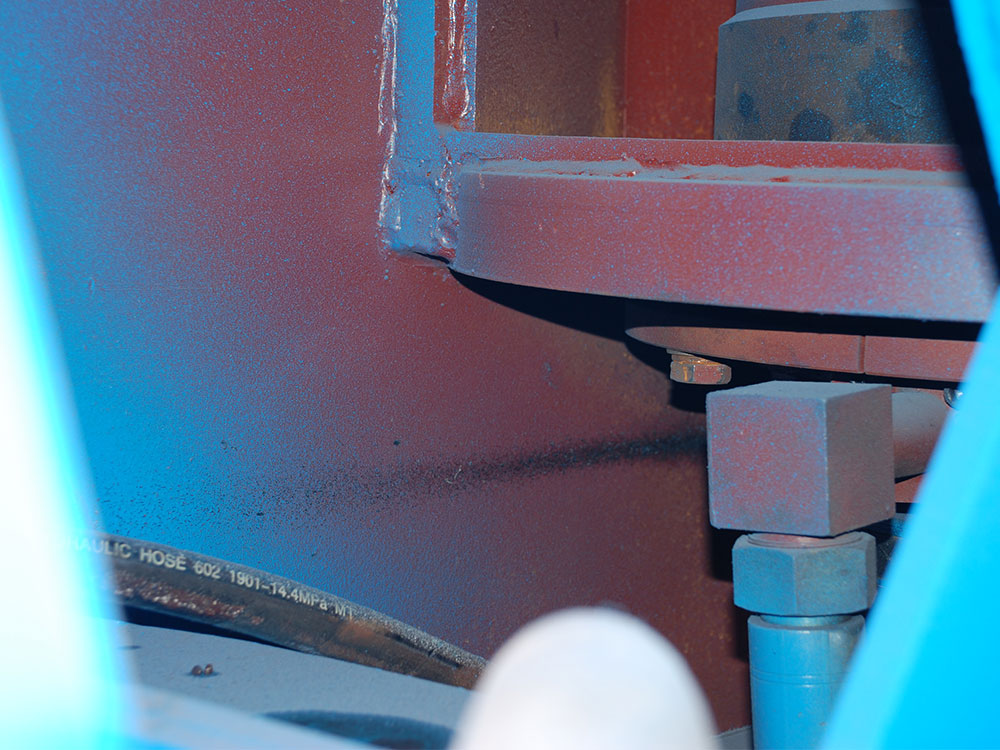

The Barmac B5100SE impact crusher has a simple structure and modular design for easy daily maintenance. Its core components have a long service life and strong wear resistance, reducing replacement frequency and lowering operating costs. In addition, the operation and debugging of the equipment are simple, with short downtime, which helps to improve the stability and continuity of the production line.

Wide applicability

Barmac B5100SE impact crusher is not only suitable for the production of sand and gravel aggregates, but also for various fields such as mineral processing and industrial ores. Its design can be flexibly adjusted to meet the needs of different materials and has strong adaptability. This equipment can provide ideal crushing effects for both hard rocks and medium hardness ores.

Excellent environmental performance

During the crushing process, Barmac B5100SE impact crusher effectively controls dust and noise emissions, meeting modern environmental standards. This is a reliable choice for production environments with high environmental requirements, ensuring that the production process is greener and meets the requirements of sustainable development.

Stable and reliable, suitable for long-term use

As part of the Barmac series, the B5100SE impact crusher model inherits the brand's consistent durability and is capable of long-term stable operation under harsh working conditions. The selection of components for the equipment is strict and the manufacturing process is exquisite, making it suitable for various complex working environments and long-term high-intensity use.

Barmac B5100SE impact crusher accessories and maintenance working principle

The working principle of the Barmac B5100SE impact crusher is based on the "stone to stone" technology, which achieves efficient crushing through material collision. This design concept places the material inside the crushing chamber and uses the centrifugal force generated by the high-speed rotating rotor to throw the material towards the lining plates or layers around the crushing chamber, completing the crushing process by colliding with each other. Unlike traditional crushers that rely on mechanical components to directly squeeze materials, the "stone hitting stone" principle significantly reduces the wear and tear of equipment components, extends the service life of equipment, and reduces maintenance frequency and operating costs. In actual operation, materials enter the center of the rotor through the feeding port and are thrown out at high speed as the rotor accelerates, causing violent collisions with the material layer or lining plate inside the crushing chamber. The material will also form a protective layer during the crushing process, further reducing wear and tear on the equipment. This crushing method not only improves the crushing efficiency, but also effectively controls the generation of excessive fine powder, making the finished product uniform in particle shape and stable in quality. In addition, the working principle of Barmac B5100SE impact crusher makes it highly energy-efficient, reducing power consumption and suitable for energy-saving production needs. Its design is also easy to adjust, and the particle size of the discharge can be flexibly adjusted according to different materials and production needs, making it an ideal choice for fields such as ore processing and sand and gravel production.

Barmac B5100SE impact crusher accessories and maintenance technical parameter

| Output | 30-60t/h | Feed port size | 35×40mm |

| Discharge size | 0-5mm | Machine weight | 7t |

| Feed size | 35-50mm | Motor power | 90-180KW |

Barmac B5100SE impact crusher accessories and maintenance Case studies and customer reviews

As the head of a mining company, we chose the Barmac B5100SE impact crusher for our project in Cairo, Egypt, and its performance has exceeded expectations. At the beginning of the project, we need an equipment that can efficiently process sand and gravel while producing high-quality finished products. After multiple investigations, Barmac B5100SE impact crusher was ultimately chosen. This device, with its "stone to stone" crushing principle and excellent particle shape control, has significantly improved our production efficiency. Barmac B5100SE performs particularly well in fine crushing of sand and gravel. The ores in Cairo are mostly of medium to high hardness, and traditional equipment experiences significant wear and tear under these materials. However, B5100SE impact crusher achieves crushing through the mutual impact between materials, effectively avoiding excessive wear and tear on the equipment itself and significantly reducing maintenance costs. In addition, the particle size control of the discharge is fine, and the finished product has excellent particle shape, fully meeting the high standards of the construction industry.