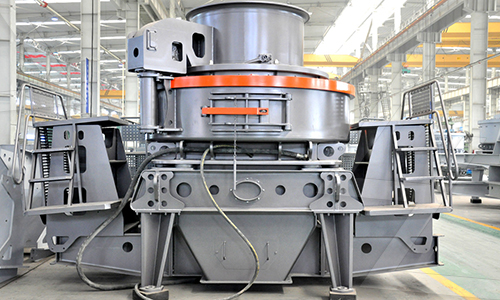

Artificial sand making industry gradually arisen, drive the whole engineering machinery technology of heavy mineral processing equipment and technological process of the research and improvement. As an important part of sand production line of sand making machine, due to its important position in the in the mechanism of sand production, so the components of solid and durable becomes important. The industry believes that the sand making machine, is crucial for material injection device is an important component of impeller, its work stability determines the associated with conveyor, feeder, the working efficiency of the separator, etc.

The working principle of sand making machine impeller and its own characteristics:

Impeller is an important part of sand making machine is also one of the most vulnerable parts, because the material is complete the distribution of the emission in impeller, if improper operation, it is easy to cause impeller material abrasion, so we should be very careful in the operation of the specific work and case because do not pay attention, accidentally triggering a series of production accidents. We know that the impeller is installed on the spindle assembly upper shaft head, with a taper sleeve and linkage pass button distance, high speed, and the material from the center of the impeller on the part of the feeder into the feeding tube into the center of the impeller. Fabrics by the impeller center cone materials uniform will be assigned to the impeller of the launch port, the launch port exports, equipped with wear-resistant block made of special material, can be replaced. Impeller material will be accelerated to a certain velocity projectile, the impact to the vortex material crushing cavity lining, with strong since shattered, between the impeller cone hat and wear resistant block, obscene but with, so as to protect it from wear and tear. Is: that should be paid attention when the device stop before the stop discharging device to stop before feeding, feeding should be sustained even, strictly abide by the material specification requirements, otherwise, it is easy to impeller due to material wear.

Welcome to my company’s production base in the choose and buy various types of sand making machine, if you are interested in, leave a message to tell us, we will contact you in time! Website customer service 24 hours online, help you answer at any time.