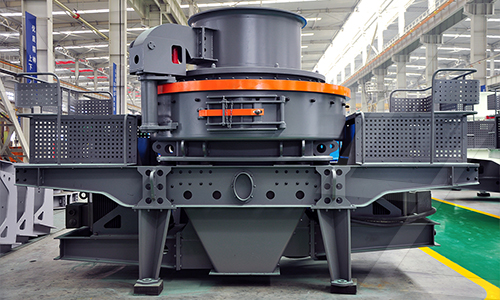

The pebbles sand making machine is a kind of special equipment specializing in building sand, stone. We Liming heavy industry production of pebbles sand making machine is a kind of high energy low consumption equipment with international advanced level, the application of finished product quality is good, the output of grain shape is a cube, more performance in all kinds of ores fine broken equipment plays an irreplaceable role. Below for everyone to make a brief introduction of our pebbles sand making machine, welcome consulting the details of the service.

We produced the pebbles sand making machine is everyone acquaint with of vertical shaft impactor system sand machine, also called PCLS sand making machine. The pebbles sand making machine is the use of high speed movement of the material to each broken shattered by the friction between material and material. Pebbles sand making machine starts, the material from the machine above into the crusher, a distributor materials can be divided into two parts, part from the distributor in the middle to high speed rotating impeller, the impeller is accelerated rapidly, within its neutral acceleration speed can reach hundreds of times, and then at the speed of 60-70 meters per second from three mass ejection out uniform distribution of the flow passage of impeller, falling around since the first with the separator to receive part of the impact the material being broken, and then sank shock to nest together cavity material layer, is material lining rebound, oblique upward shocks to the vortex chamber by twice so that multiple risk impact, friction and abrasive grinding, and also has a cosmetic effect.

Advantage in pebbles sand making machine:

1. Simple and reasonable structure, since the strike is broken and the use of ultra low cost;

2. The unique design of bearing installation and advanced main shaft makes the machine has the characteristics of heavy load and high speed;

3. At the same time with finely, coarse grinding function;

5. Smooth operation, work, low noise, high efficiency and energy saving, high crushing efficiency;

6. Small under the influence of material moisture content, water content can be up to 8%;

7. Parts, low loss, all wearing parts adopt high quality wear-resistant materials at home and abroad, long service life. A small amount of wear parts made from special hard wear-resistant material, small volume, light weight, easy to replace the accessories;

8. Vortex chamber design is clever, internal flow from circulation, small dust pollution;

10. Installation is diversiform, portable installation;

11. The product layer cube, bulk density is big, small iron pollution, can do stone plastic machine.