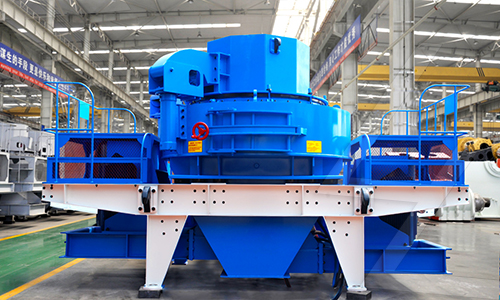

Sand production line by the feeder, jaw crusher, fine jaw crusher, sand making machine, vibrating screen, sand washer, belt conveyor, concentrated electronic equipment, to meet different customers demand, can form a complete set of cone crusher, dust removal equipment, etc. Can be used for hard limestone, granite, basalt, cobble, pebbles, slag of a variety of materials such as aggregate and artificial sand system operation. Suitable for water and electricity, building, building material, highway, the application of the urban construction and other industries.

1. The basic technological process is introduced: sand production line

Material (limestone, granite, basalt, gneiss, pebble, pebbles, etc.) through the feeder evenly feeding mandibles crusher preliminary broken, finished product after crushed by belt conveyor to finely further broken jaw crusher, stone by belt conveyor after the secondary crushing to sand making machine is broken again, and again the broken stone by belt conveyor after delivery to sieve screening out the different specifications of stones, satisfy clients’ demand for particle size of gravel pile by belt conveyor to finished product, unqualified stones by belt conveyor to return to the sand making machine is broken again, form a closed circuit cycle many times to complete.

2. Sand making production line performance is introduced:

Company configuration of the system of sand production line a high degree of automation, high broken rate, low operating cost, energy saving, low pollution, sand production mechanism in line with national standards, building sand product granularity, grain shape good, the grading is reasonable. Main equipment of the production line according to the customer for the sand sand specifications, production and customer. According to customer’s production site condition, to provide customers with comprehensive technological process planning and technical support, can be designed according to the customer’s actual installation conditions of non-standard fittings, etc.

Welcome to consult customer service, to understand our company‘s production line equipment. Buy our products, our technical staff will provide you with professional production line configuration.