Larger rock types processed by the stone pulverizer industry include limestone, granite, dolomite, traprock, sandstone, quartz, and quartzite. Minor types include calcareous marl, marble, shell, and slate. Major mineral types processed by the pulverized minerals industry, a subset of the crushed stone processing industry, include calcium carbonate, talc, and barite. Industry classifications vary considerably and, in many cases, do not reflect actual geological definitions.

Rock and crushed stone products generally are loosened by drilling and blasting and then are loaded by power shovel or front-end loader into large haul trucks that transport the material to the processing operations. Techniques used for extraction vary with the nature and location of the deposit. Processing operations may include crushing, screening, size classification, material handling and storage operations.

The stone that is too large to pass through the top deck of the scalping screen is processed in the secondary crusher. Cone crushers are commonly used for secondary crushing (although impact crushers are sometimes used).The output from the secondary crusher and the throughs from the secondary screen are transported by conveyor to the tertiary circuit, which includes a sizing screen and a tertiary crusher.

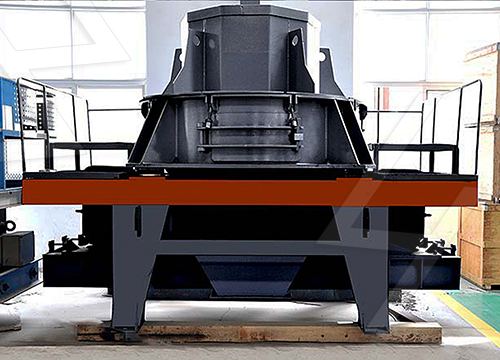

Liming Heavy Industry (Shanghai) are one of the world’s leading manufacturers of stone pulverizer, stone crusher supplier. Based on decades of experience, our research and development work has become an integral part of our processing equipment. Customers all over the world benefit from our products.