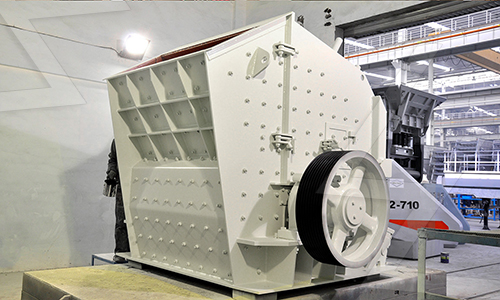

Counterattack broken maintenance matters needing attention

Reaction type crushing function processing under 100-500 - mm length material, resistant to pressure up to 350 million mpa, big crushing ratio, material after broken cube grains, etc. Widely used in building materials, ore crushing, railways, highways, energy, transportation, energy, cement, mining, used to finely materials in chemical industry, etc. The row partical size can adjust, broken specification diversification.

Counterattack crusher maintenance considerations:

(1) counterattack crusher operation in the process of routine inspection should be done regularly, when found to have abnormal sound or bearing temperature higher than 700 c, it is necessary to stop the machine immediately to check and eliminate the fault in time before I can continue to boot.

(2) after the machine working normally feeding, feeding wants even, should prevent iron with hard objects. Must stop feeding before stop, stop within the material is broken and then power motives.

(3) the counterattack crusher after repair or adjust the discharging mouth, should first turn the rotor by manpower, confirm rotor and other parts without friction and sticking phenomenon and flexible rotation, can start the motor.

(4) should always check whether the bearing seal is good, bearing grease should be filling every month, every three months shall all be clean oil change and replace felt.

(5) check whether the fastener is loose, check should focus on the rotor side compression screw of clamp plate hammer, prevent loose pressure plate, plate hammer at both ends with daughter, and the body touch attack, damage to the parts.

(6) to ensure that the operating personnel and equipment safety, are prohibited in machine repair, adjust and clean up, forbid to open the door.

(7) when broken product particle size is too large, should stop check board hammer wear, to prevent the rotor is worn. When the board hammer adjust 180 due to wear and tear. Again, when using, should make every board hammer equal in weight and balance, to prevent vibration in the aftermath of the machines on.