Titanium white pigment on the crushing particle size and size distribution

Titanium white pigment on particle intrusive and granularity distribution have very strict requirements. Industrial titanium white way with wet and dry broken broken. Wet crushing equipment with wet ball mill and sand mill, all carried out in water medium.

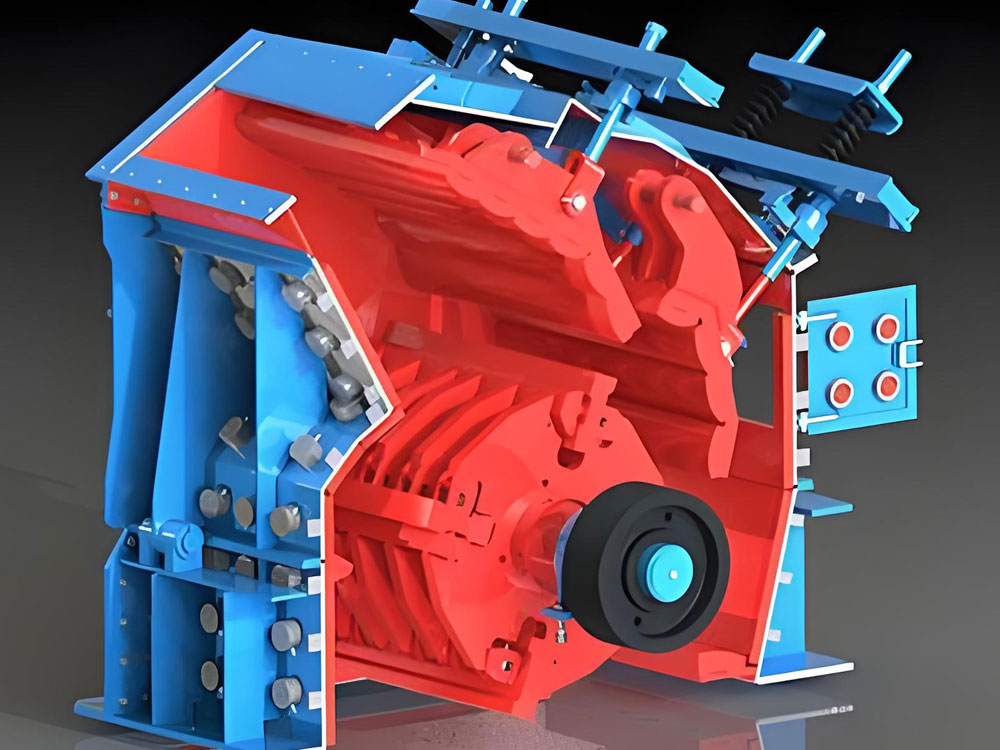

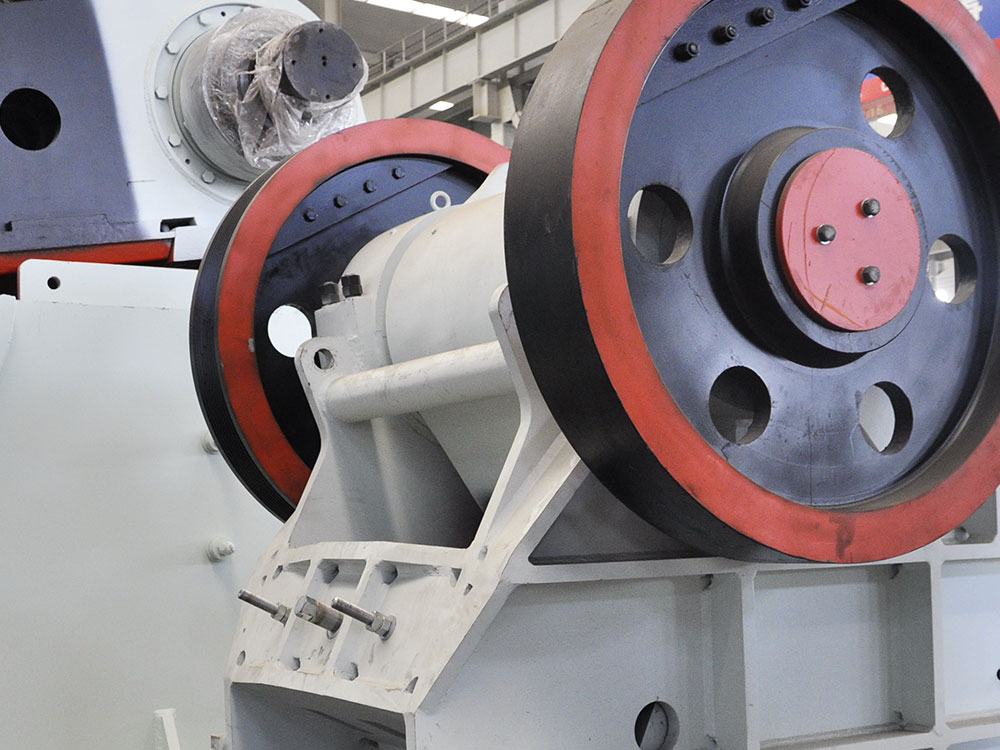

Dry crushing equipment with Raymond mill, hammer mill, centrifugal grinding machine, the flow can mill (airflow crusher), etc. Breakage is not a single grinding equipment, but by two or more than two kinds of combination grinding equipment, such as the calcines approved by ring roller grinding after the first airflow crushing, repeatedly grinding is also useful to the same kind of equipment, such as secondary air damage. Below in the case of Raymond mill, crushing principle to introduce you to it.

Raymond mill is also called the ring roller mill, of titanium white industry with wheel ring roller mill. Raymond mill is used to crush the titanium white pigment products, can also be used on the primary crushing of titanium white pigment. Because of its internal with separator, and other dry mechanical grinding machine (such as centrifugal mill), products in the coarse particles are much less. Other materials wear less pollution, large output, save electricity, thus abroad in for sharp titanium type and rutile type titanium dioxide primary crushing and sharp titanium type titanium dioxide of secondary breakup (water concentration, dry crushing).

Liming team since its inception has been the pursuit of innovation and excellence, and has been using high-quality products, professional skills and sincere services to help customers create more revenue, take concrete actions to promote the construction of the world's machinery manufacturing industry. If you are interested in our products, or you want to base our production site visits, please contact the site customer service 24 hours for you!