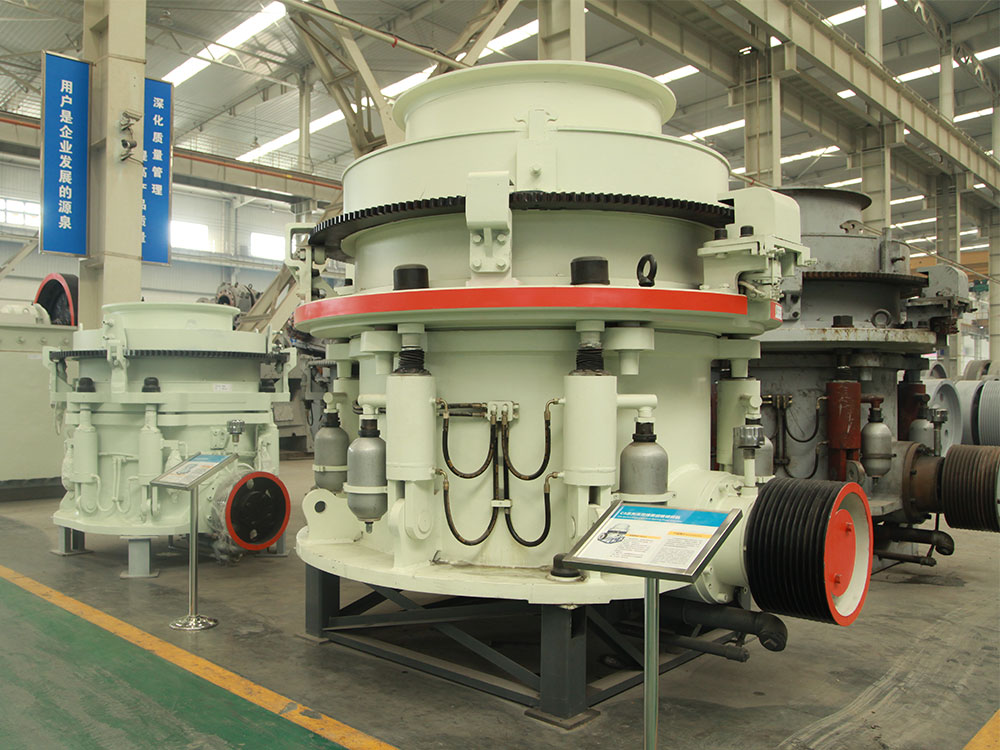

GP100S Stone Cone crusher, Crushing Plant

The GP100S cone stone crusher, specially designed for the field of ore processing, leads the industry trend with its cutting-edge crushing technology. This model not only achieves a qualitative leap in crushing efficiency and ensures efficient and stable operating performance, but also significantly improves production efficiency by optimizing the production process. In terms of construction durability, GP100S uses high-strength high-manganese steel materials to build its core crushing components-the die and jaw plate. The wear-resistant properties of these components significantly extend the service life of the equipment and help users reduce the risk of accidents. Additional costs resulting from frequent replacement of parts. At the same time, in order to meet diverse crushing needs, this model also provides a rich set of accessories, including various types of bowl liners and jaw plates adapted to different working conditions. All this is due to the exquisite craftsmanship and strict quality control of leading manufacturers such as Guangdong Liebo Heavy Technology Co., Ltd., ensuring the excellent quality and worry-free after-sales service experience of GP100S in the market.

GP100S Stone Cone crusher Applications

In the metallurgical industry, GP100S Stone Cone Crusher undoubtedly occupies a pivotal position. As a key equipment for ore pretreatment, it can accurately cope with the crushing challenges of metal ores such as iron ore and manganese ore. Through fine crushing technology, it outputs raw materials with uniform particle size and high quality, laying a solid foundation for subsequent smelting processes. This high-quality raw material not only improves smelting efficiency, but also significantly optimizes the quality of the final product, contributing an indispensable force to the prosperity and development of the metallurgical industry.

Turning to the chemical industry, GP100S also demonstrated its strong adaptability and efficiency. Faced with the diversified crushing needs of ore and mineral raw materials, the equipment can easily achieve the fine processing of raw materials with its excellent crushing capacity, providing precise particle size control for the preparation of chemical raw materials. This feature not only meets the chemical industry's stringent requirements for highly refined raw materials, but also provides strong support for the quality improvement and diversified development of chemical products.

In power production, GP100S also plays a vital role. As a powerful tool for crushing key raw materials such as coal and limestone, it ensures that power generation equipment can continuously obtain stable, high-quality fuel and desulfurizer. This advantage not only directly improves power generation efficiency and reduces operating costs, but also plays a positive role in reducing pollutant emissions and promoting green power generation. Therefore, the wide application of GP100S Stone Cone Crusher in the power industry is not only a full recognition of the performance of the equipment, but also a powerful practice of the concept of green, efficient and sustainable development.

GP100S Stone Cone crusher Advantages

Efficient crushing capability

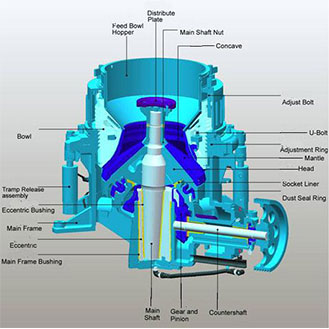

GP100S Stone Cone Crusher, with its innovative crushing mechanism, maximizes the precise coordination of the moving cone and the fixed cone, and quickly and accurately converts the material into the finished product of the required particle size through efficient extrusion and shearing force. Its excellent crushing efficiency and huge processing capacity ensure that even in a large-scale production environment, it can easily meet the needs of efficient output and inject strong power into the production line.

Wear-resistant parts optimization

In order to meet the challenges of long-term high-intensity crushing operations, GP100S has carefully designed and selected key components. Core components such as the crushing wall and the mortar wall are all made of top-grade wear-resistant materials, and their wear resistance and service life are further improved through unique process treatment. This optimization strategy not only significantly reduces the downtime and replacement time caused by component wear, but also greatly reduces maintenance costs, providing a strong guarantee for the continuous and stable operation of the production line.

Intelligent control system

Entering the era of intelligence, GP100S Stone Cone Crusher is also unwilling to lag behind and is equipped with an advanced intelligent control system. The system is like the "brain" of the equipment. It can monitor and analyze the operating status and crushing effect of the equipment in real time, intelligently adjust the working parameters to adapt to different working conditions, and ensure that the equipment is always in the best performance state. In addition, the intelligent control system also has forward-looking fault warning and self-protection functions. Once a potential problem is found, it will take measures to intervene immediately, effectively improving the safety and reliability of the equipment and reducing the risk of failure.

Environmentally friendly and energy-saving design

While pursuing high efficiency and durability, GP100S also does not forget the social responsibility of environmental protection and energy conservation. During the design and manufacturing process of the equipment, it strictly follows the green production principles and adopts advanced sealing and dust removal technology to effectively curb the spread of dust and noise pollution, bringing significant improvements to the production environment. At the same time, by continuously optimizing the power system and transmission mechanism, it has achieved a significant reduction in energy consumption and a significant improvement in energy utilization efficiency, contributing to the sustainable development of the enterprise.

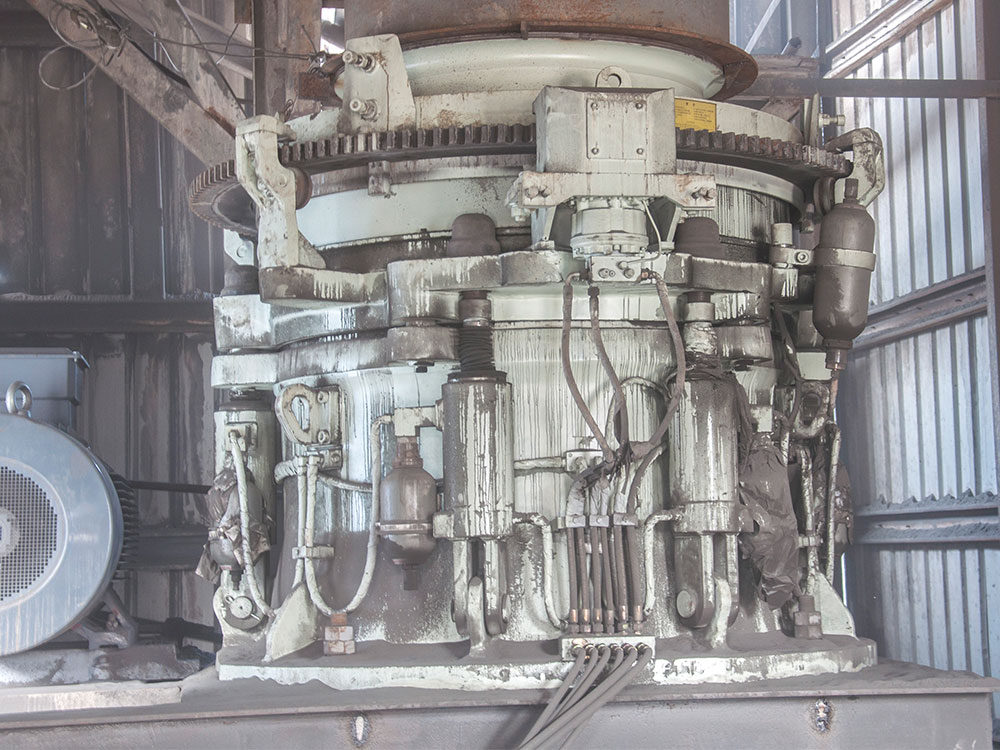

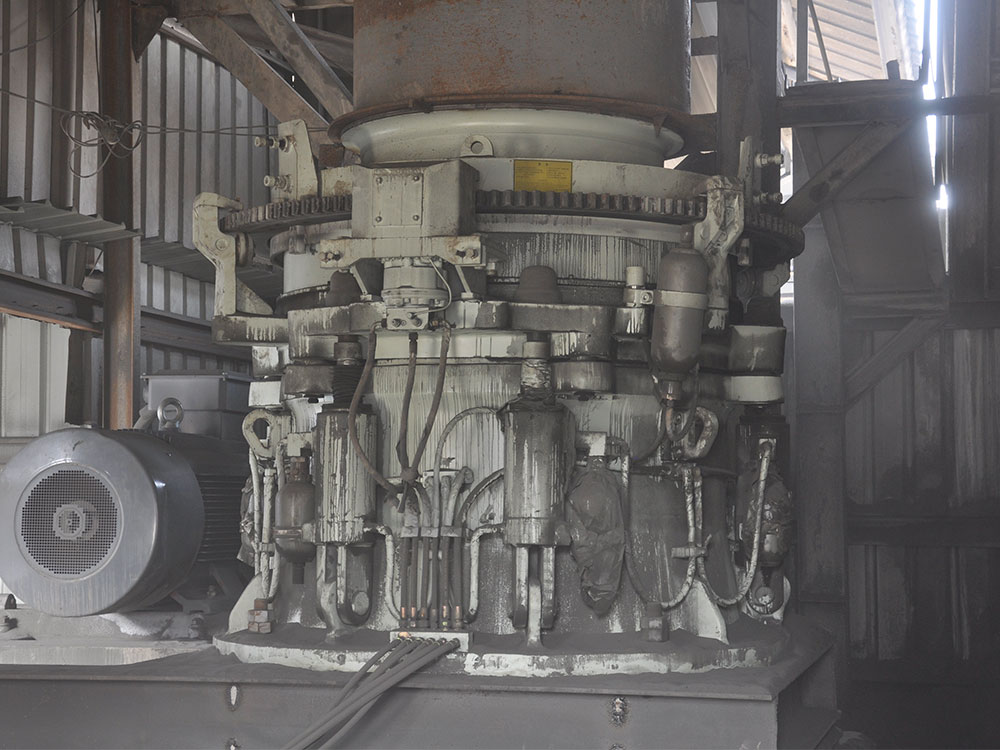

GP100S Stone Cone crusher Principle

GP100S cone crusher follows the advanced concept of laminated crushing. Its core operating principle is that the rotation and lifting movement of the moving cone components form a dynamic coordination with the fixed cone to jointly build an efficient crushing environment. When the material enters this carefully designed crushing area through the feeding system, it will immediately be subjected to the powerful and complex mechanical effects between the moving cone and the fixed cone - these effects include high-intensity extrusion, fine shearing and complex bending effects, which act together on the material to cause it to be gradually crushed and refined. In addition, the material particles will naturally collide and squeeze each other in the crushing chamber. This spontaneous crushing process helps to achieve uniform particle size. Once the particle size of the material is reduced to a size large enough to pass through the gap between the moving cone and the fixed cone, they will naturally slide to the bottom of the crushing chamber, completing the entire crushing process.

GP100S Stone Cone crusher Technical Parameters

| Model NO. | GP100 | After-sales Service | All The Time |

| Materials | Limestone | Specification | 2600X2250X2860 |

| Inlet Size | 250×400mm | Origin | China |

| Warranty | One Year | Production Capacity | 100sets |

| Transport Package | Shanky | Application | Construction |