Dressing crusher equipment to regular cleaning

Mine is the foundation of modern industry, our country has a lot of mines. After mining is a complex process, but also for broken ore dressing. Mining machinery for mining, crushing, choose don't mechanical equipment. In mining crushing screening link, will use the crusher equipment, including jaw break, cone break using more. After mining machinery also extends to the building materials field, only the crushing equipment is more diverse. Jaw crusher, counterattack crusher, impact type system sand machine, single cylinder hydraulic cone crusher, hydraulic cone break can be applied to sand production. The equipment in the machinery industry is still in the mining machinery processing equipment classification.

So many dressing crusher equipment, the annual corrosion loss is a huge number. Rust is fluffy state, will continue to occur, in hot and humid environment quickly and also reduce the strength of steel. Effective rust removing rust not only save more resources, but also provide help for production safety. The following methods for the derusting and rust proof:

1. The chemical cleaning method, mainly using acid react with metal oxide, so as to get rid of high efficiency sand making machine on the surface of the metal corrosion product of a cleaning method, known as pickling, the rust removal only operate in the workshop;

2. High pressure water abrasive cleaning: using high pressure water jet impact and water lever effect to remove sand machine of sheet metal corrosion and coating. Its characteristic is no dust pollution, not damage the steel plate, greatly improve the efficiency of rust removal, can reach more than 15 m2 / h, derusting quality is good. But after rust removal of steel rust easily return to with wet cleaning coating, coating for general performance of coating has a great influence on the coating;

3. Small pneumatic or electric rust removing: mainly powered by electricity or compressed air, appropriate cleaning device assembly, reciprocating motion or rotation, to adapt to the cleaning requirements of various occasions;

4. Apply: anti-oxidation paint on the surface of iron products with mineral oil, or baked enamel paint, coating, etc. In the steel surface using methods such as electroplating, hot dip plating layer is not easy to rust on the metal, such as zinc, tin, chromium, nickel, etc. These metal surface can form a dense layer of oxide film, so as to prevent iron products substances such as contact and water and air to produce rust. Iron products can also be chemically generated on the surface of a layer of dense and stable oxide film in order to prevent the iron rust.

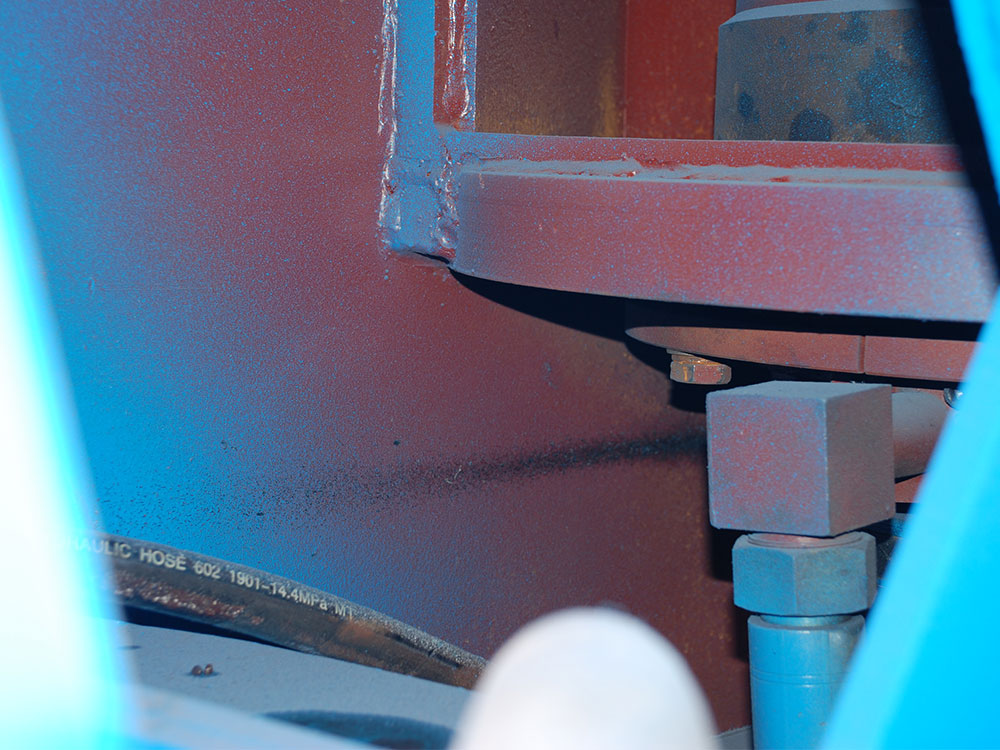

Mine production line equipment is usually open, the sun, the frost, rain after a long time, the anticorrosive paint is to be out of the crusher equipment, will cause varying degrees of corrosion, internal if insist on production, corrosion will be automatically removed. Want to control corrosion, need every year to do some cleaning equipment, coated with anticorrosive paint. In addition, can also build airtight concrete construction, put equipment inside, avoid the generation of dust, or build a tower type stone production line, covers an area of small, can at any time to do rain protection, reduce the amount of rust.