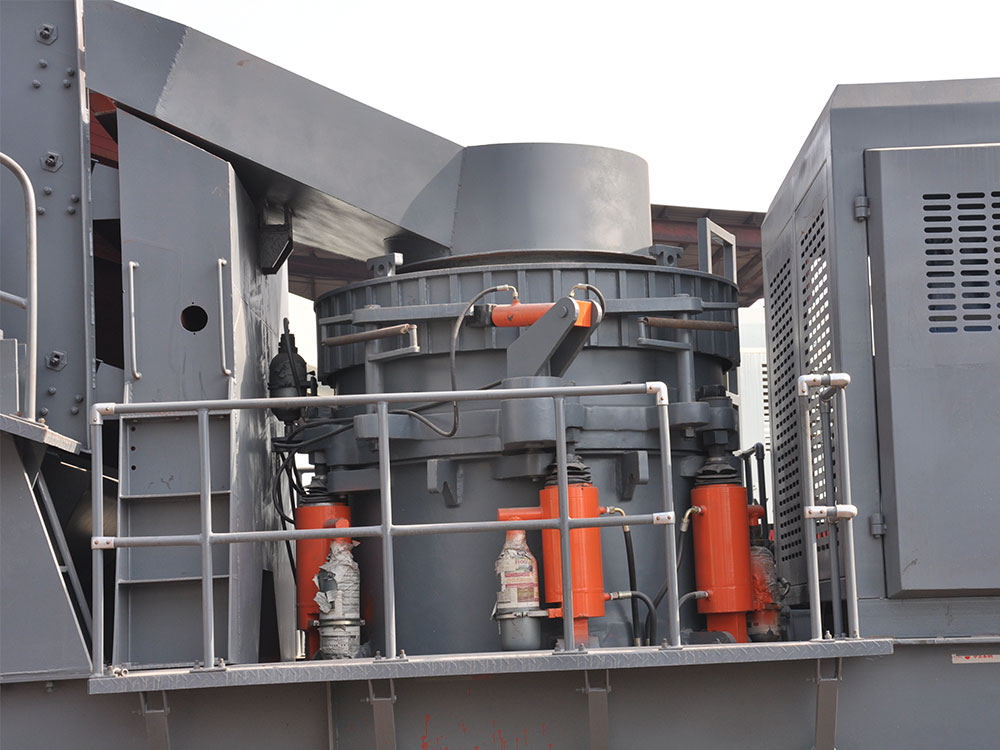

LT200HP Mobile cone crusher

Thanks to the application of direct belt drive technology, the latest models have achieved significant improvements in fuel economy compared to similar products with hydraulic drive in the past, saving at least 15% of fuel consumption. This improvement not only reduces operating costs, but also reflects a positive contribution to environmental protection, reducing pressure on natural resources by reducing energy consumption. Direct belt drive, with its efficient and direct energy transmission method, effectively improves the working efficiency of the equipment and brings users a more economical and environmentally friendly experience.

LT200HP Mobile Cone Crusher Applications

With its excellent performance and wide applicability, this product has been deeply applied and highly recognized in many key industries. In the field of dry mortar, as one of the core equipment, it helps the production process to be efficient and smooth, ensuring stable and reliable product quality; in the desulfurization link of power plants, its efficient processing capacity contributes to environmental protection and effectively reduces pollutant emissions; at the same time, in the mineral processing industry such as quartz sand, this product also shows extraordinary strength, helping enterprises to improve production efficiency and reduce operating costs.

LT200HP Mobile Cone Crusher Advantages

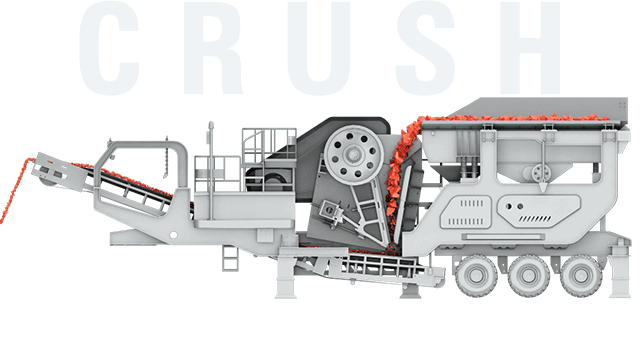

Efficient Deployment with Integrated Design

With its integrated installation method, the integrated unit completely simplifies the complex site layout and infrastructure construction process required for traditional split components, significantly reducing material consumption and construction time. Its compact and reasonable space planning not only optimizes site utilization efficiency, but also gives the unit a high degree of deployment flexibility, easily adapting to various operating environments.

Convenient operation with small turning radius

The unit realizes the ability to crush materials instantly on site, completely abandoning the traditional mode of material transportation and then crushing, greatly reducing logistics costs. Its compact body design ensures a very small turning radius, allowing it to maneuver flexibly and operate efficiently in both narrow spaces and complex terrains.

Economical and efficient operation mode

Through the careful optimization of the ship-shaped steel frame and modular assembly technology, the unit not only has a solid structure and is easy to transport, but also realizes the flexible energy supply of oil-electric hybrid power. This innovative design ensures that even in remote areas where power supply is inconvenient, the unit can operate stably without interrupting the production process, guaranteeing safe and efficient operations. In addition, the unit provides diversified crusher configuration options and non-standard customization services to fully meet the user's individual needs.

Strong Adaptability and Flexibility

The mobile crushing plant demonstrates excellent adaptability, whether as a stand-alone unit to perform coarse or fine crushing and screening tasks, or as part of the system configuration and other units to work together, can be easily. Its flexible power supply solution supports the joint power supply of complex process systems, demonstrating a high degree of flexibility and customization.

The HP200 cone crusher sets a new benchmark in hard rock processing with its superior crushing capacity and high-capacity design. This rigorously proven device is designed to handle the most challenging crushing tasks and can easily handle all types of hard rocks including granite and basalt, ensuring that the final products such as concrete aggregates meet excellent quality standards.

Its unique chamber design is another highlight of this model, providing a variety of options to meet different crushing needs. Whether it is secondary crushing to further optimize the particle size distribution or tertiary crushing to pursue the ultimate fineness, the HP200 can easily achieve it by replacing different chambers, showing extremely high flexibility and adaptability.

It is particularly worth mentioning that the HP200 cone crusher has an amazing maximum feed size of 185 mm (7.3 inches), which means that it can directly process large pieces of raw materials, reducing the pre-crushing step, thereby significantly improving production efficiency and reducing energy consumption. This feature makes the HP200 an ideal choice for large mines, quarries and construction materials manufacturers.

LT200HP Mobile Cone Crusher Working Principle

In order to further improve the intelligence and automation level of crushing operations, the HP200 cone crusher is equipped with the market-leading IC600 automatic control system. This innovative system integrates the fully automatic crushing process control function, realizes the precise regulation of the crushing process, and ensures the stability and efficiency of the production process. At the same time, the one-button automatic start function simplifies the operation process, reduces the complexity of manual intervention, and makes the start-up and operation of the crusher more convenient and efficient. What is more worth mentioning is that the IC600 automatic control system is also equipped with advanced fault diagnosis features. This feature can monitor the operating status of the crusher in real time, detect and diagnose potential faults in a timely manner, and provide accurate information support for maintenance personnel, thereby effectively shortening the downtime of faults and ensuring the continuous and stable operation of the crusher. This advantage not only improves production efficiency, but also reduces maintenance costs, creating greater value for customers.

LT200HP Mobile Cone Crusher Technical Parameters

| C140 jaw crusher | 42 x 55 inch opening | Recently removed from service | Available for inspection or shipment |

| Operated at a cement facility crushing limestone | Includes flywheels and guarding | Recently serviced before shutdown | 250 HP motor |

| 1200 RPM | 460 V, TEFC | Feed opening | 42 x 55 inches (1 x 1.4 meters) |

| Maximum accepted Feed Size | 33 inches | Closed side setting range | 4 - 10 inches (150 - 375 mm) |

| Throughput | 325 - 840 TPH | Motor Power | 200 kW (250 HP) |

| Crusher RPM | 220 |