The Biggest Impact Crusher in China

Customer: Shandong Lunan Cement Co. Ltd.

Tengzhou , Shandong Province,

Plant Description

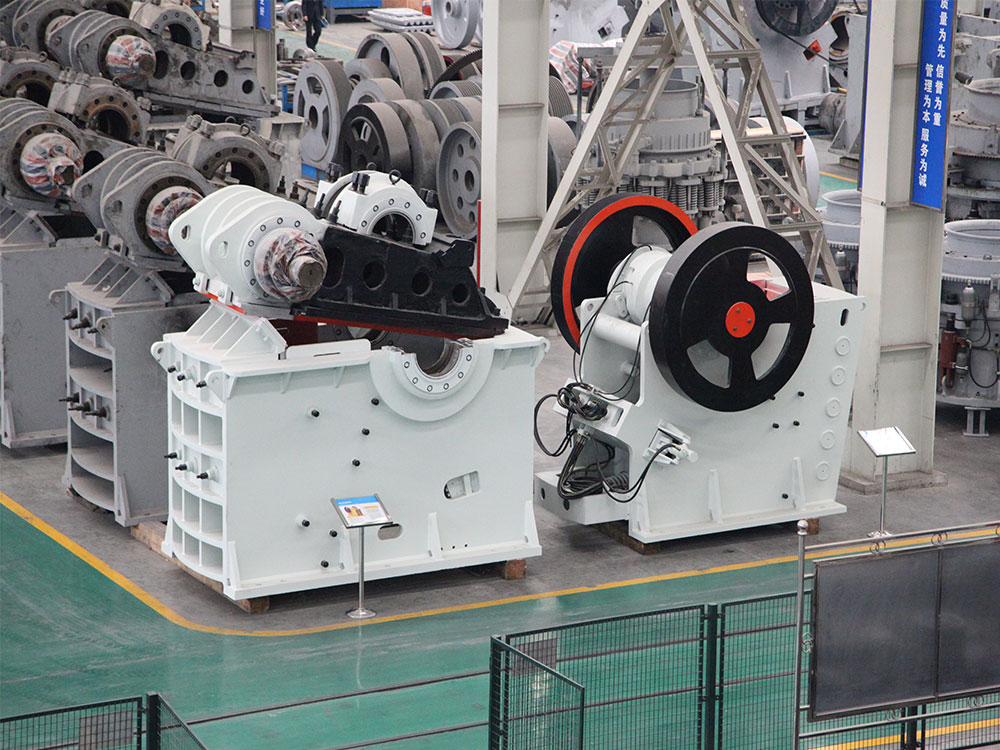

Within the framework of a new 5000 tons/day production line at the Lunan Cement Plant in

China, HAZEMAG has supplied the crusher for the stationary crushing plant installed there.

The crusher in question is the biggest impact crusher in the Chinese cement industry and

handles 1,500 tons/hr. The rotor, shaft, bearings, hydraulics and control electrics were supplied fromGermany, whereas the housing, impact aprons and vee-belt pulleys were sourced

locally inChina.

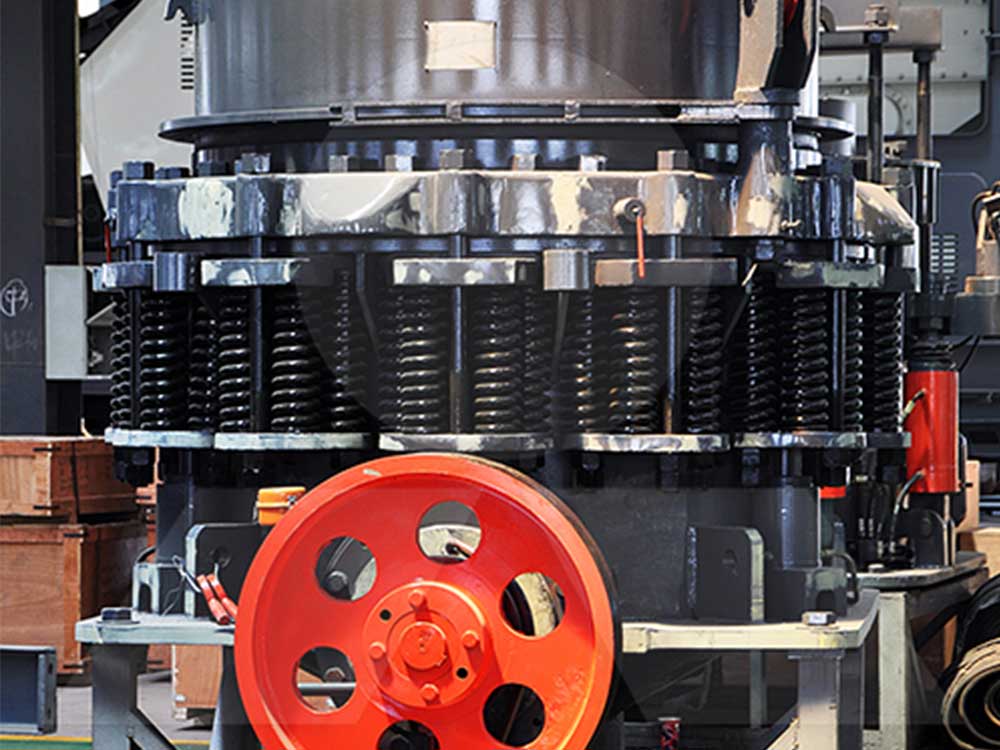

The impact crusher is fitted with the patented HAZEMAG GSK-type rotor, an extremely robust,

heavy-duty cast steel unit with a high moment of inertia which enables the crusher to handle

even the largest of rocks whilst maintaining peak capacity without affecting the rotor‘s performance. Thanks to its rugged construction, it is also relatively insensitive to ingress of tramp

metal. The one-piece blow bars are characterised by their high exploitation rate (approx. 48%);

they are locked in position mechanically by means of securing wedges which are quick and

easy to disengage, and can be turned or changed effortlessly using the special device provided.

The impact aprons and the grinding path are hydraulically mounted and adjusted, whereby any

adjustments necessary can be effected at the touch of a button. On entry of any tramp metal

or during overloading of the crusher, the impact aprons retract with a controlled action, returning automatically and immediately to their pre-set position as soon as the situation returns to

normal. This greatly reduces any damage hazard and guarantees a product of unvarying high

quality, with the presence of undesirable oversize being more or less ruled out. The crushing

gap between impact aprons and blow bars can be simply re-adjusted to allow for progressive

blow bar wear. Other distinguishing features of the crusher are its smooth running and low

noise emissions.

The housing has hydraulically-actuated hinged sections front and rear which provide for easy

access to the internals and the wear parts. In addition to its outstanding efficiency and safety

of operation, the crusher is extremely easy to service and maintain.

Technical Data For The Impact Crusher:

Feed material: Limestone

Feed size: max. 1,500 x 1,100 x 1,100 mm

Capacity: Up to 1,500 tons/hour

Impact crusher: Type AP-PMH 2525

Inlet: height approx. 2,000 mm

width approx. 2,500 mm

Rotor diameter: 2,500 mm

Rotor width: 2,500 mm

Wt. of GSK rotor: 55,000 kgs

Blow bar unit wt.: 1,295 kgs

No. of blow bars: 6

Total crusher wt.: 163,000 kgs

Installed drive rating: 1,900 kW