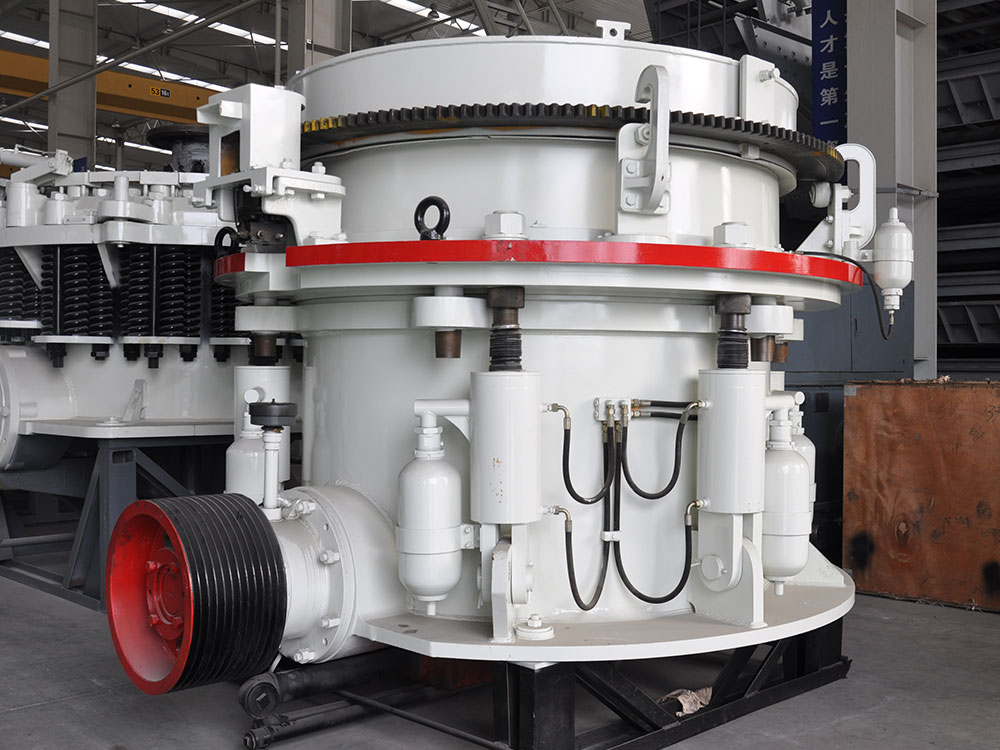

Aggregate Equipment MP1250 Cone Crusher

The MP series cone crushers are designed for material size reduction with their superior high capacity and powerful crushing force. Among them, the MP1250 cone crusher provides unprecedented flexibility and efficiency for your crushing operations. Its built-in fully automatic overload release device can quickly respond to unbreakable objects, releasing them immediately to avoid equipment damage while ensuring that the crushing force remains strong. Once the unbreakable material passes, the production settings will automatically reset to the preset state of the cone crusher. In addition, the addition of a hydraulic cleaning system further improves the availability of the equipment. Thanks to its large vertical stroke, the material can fall smoothly, ensuring that the crusher can maintain a consistent stroke capacity and maintain efficient operation throughout the service life of the liner.

Aggregate Equipment MP1250 Cone Crusher Applications

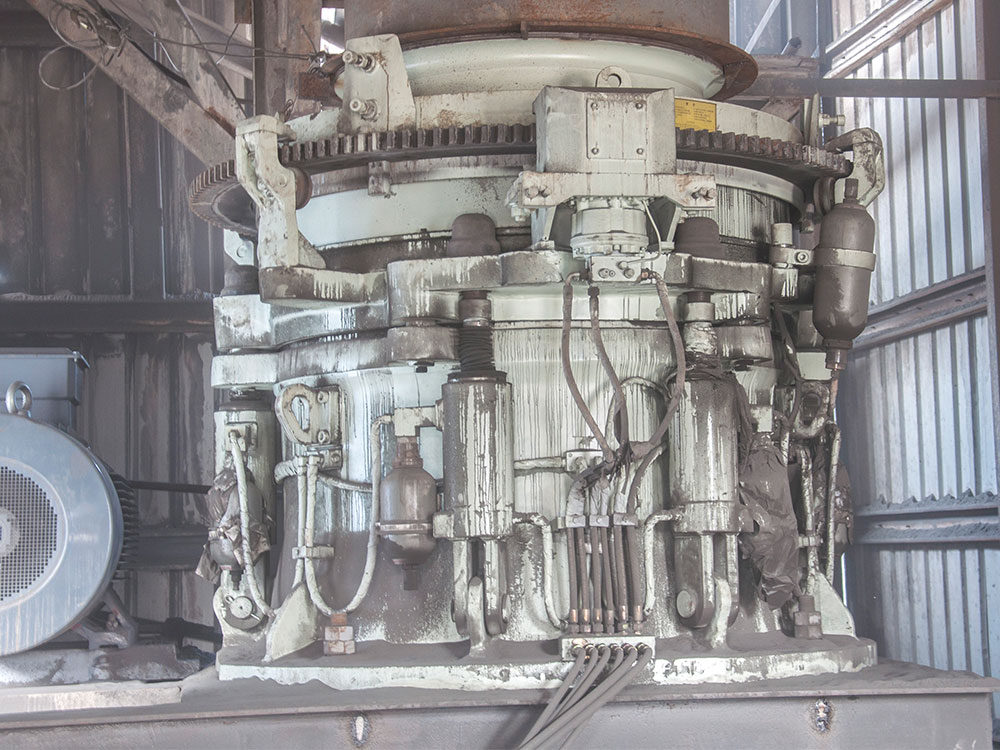

In the mining and metallurgical industries, the choice of crushing equipment is directly related to production efficiency and economic benefits. Among them, MP1250 cone crusher has become the first choice of many enterprises due to its excellent performance and wide range of application fields. This equipment is particularly suitable for crushing hard and medium-hard ores and rocks, such as iron ore, limestone, copper ore, etc., providing an efficient crushing solution for the mining and metallurgical industries.

MP1250 cone crusher has demonstrated outstanding performance in the mining and metallurgical industries with its powerful crushing capacity and stable operating status. It can easily cope with various complex geological conditions and ore properties, crush hard ores and rocks into the required particle size, and provide high-quality raw materials for subsequent processing processes. This not only improves production efficiency, but also reduces energy consumption and operating costs, creating significant economic benefits for the enterprise.

In addition to its wide application in the mining and metallurgical industries, the MP1250 cone crusher also plays an important role in the construction industry. During the preparation of building materials, stones need to be processed and crushed to meet the needs of different construction projects. MP1250 cone crusher, with its efficient crushing capacity and precise particle size control, can quickly break stones into building materials that meet the requirements, such as gravel, sand, etc. This not only improves the production efficiency of building materials, but also ensures the quality and stability of building materials, providing strong support for the sustainable development of the construction industry.

In addition, MP1250 cone crusher is also widely used in the road construction industry. In road construction, a large amount of crushed materials are needed to lay the roadbed and pavement. MP1250 cone crusher can crush these materials into the required particle size, providing high-quality crushed materials for road construction. This not only improves the efficiency and quality of road construction, but also reduces construction costs and provides a strong guarantee for the rapid development of transportation infrastructure.

Aggregate Equipment MP1250 Cone Crusher Advantages

Dual improvement in production capacity and efficiency

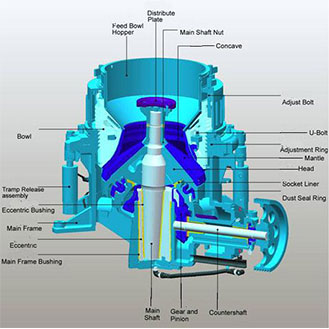

This equipment adopts a unique structure in which the main shaft is fixed and the eccentric sleeve rotates around the main shaft, which can carry higher crushing power. Through carefully designed eccentricity, cavity shape and motion parameters, the production capacity and work efficiency of the equipment have been significantly improved.

Layer compression crushing mechanism

Utilizing the layer compression crushing principle, the crushing process is mainly carried out between materials, which not only improves the crushing efficiency, but also optimizes the particle shape, making it an ideal choice for producing high-quality aggregates.

Stable and intelligent operating capabilities

The equipment is equipped with a convenient operation and maintenance system and integrates automation functions such as lubrication return flow monitoring, horizontal axis speed monitoring, vibration monitoring and automatic feeding control, which effectively extends the service life of the equipment and ensures the stable operation of the crushing system. and intelligent management.

Comprehensive upgrade of control system functions

The control system adopts visual sensor data display, freely configurable alarm solutions, and a more flexible Internet measurement and control docking solution, providing users with a more intuitive and efficient control experience.

Aggregate Equipment MP1250 Cone Crusher Working Principle

Driven by the eccentric sleeve, the cone of the cone crusher performs a pendulum motion, which drives the crushing wall to strongly squeeze and rub the material between the mortar walls. According to the theory of laminated crushing, the material will be crushed and gradually refined according to its inherent texture characteristics by forces from all directions, and finally generate stable stone particles that meet the requirements. These particles that meet the discharge standards will naturally fall from the gap formed by the crushing wall and the pendulum, while the materials that do not meet the standards will continue to be crushed until all materials meet the specified size requirements.

Aggregate Equipment MP1250 Cone Crusher Technical Parameters

| 13 mm (0.5 inches) | 770-915 mtph (850-1010 stph) | 25 mm (1 inch) | 1145-1510 mtph (1260-1665 stph) |

| 19 mm (0.75 inches) | 900-1125 mtph (990-1240 stph) | 38 mm (1.50 inches) | 1720-2190 mtph (1895-2415 stph) |

| 50 mm (2 inches) | 2290-3025 mtph (2525-3335 stph) | Complete crusher weight | 153,985 kg (339,479 lbs) |