The difference between cone crusher and jaw crusher

With the rapid development of the building, metallurgical and other industries, a variety of professional industry production equipment also arises at the historic moment, and rapid innovation and upgrading, became all kinds of indispensable important equipment in production line. Which used in the production line in the early stage of crusher is the most important, is directly related to the follow-up material processing. To briefly talk about the following two representatives of crusher equipment, cone crusher, and jaw crusher.

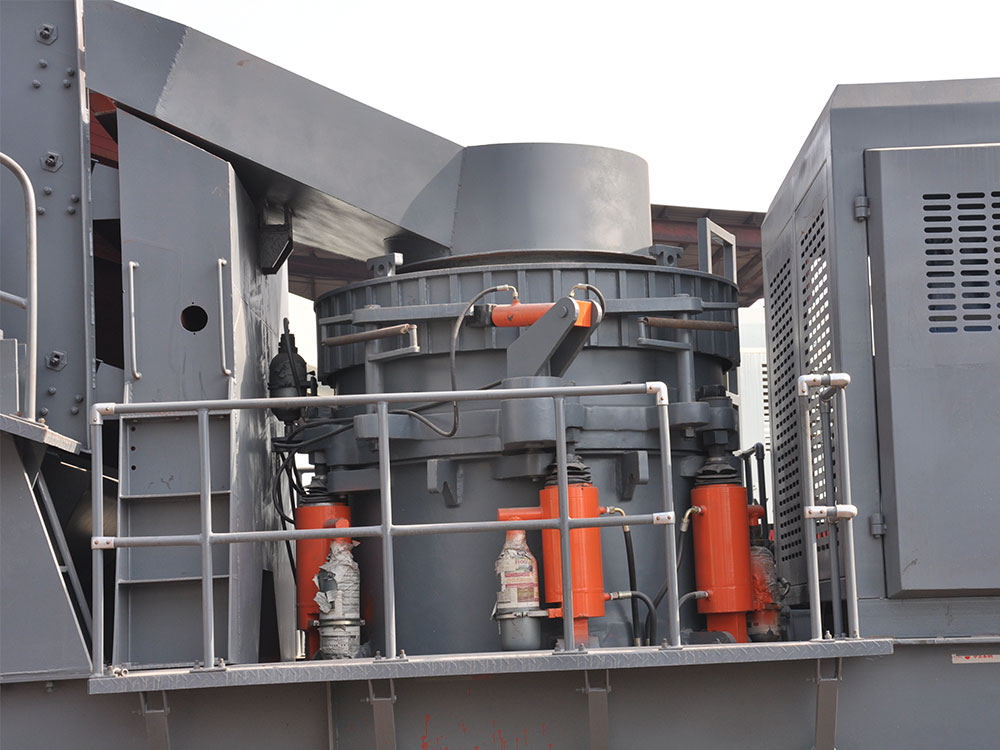

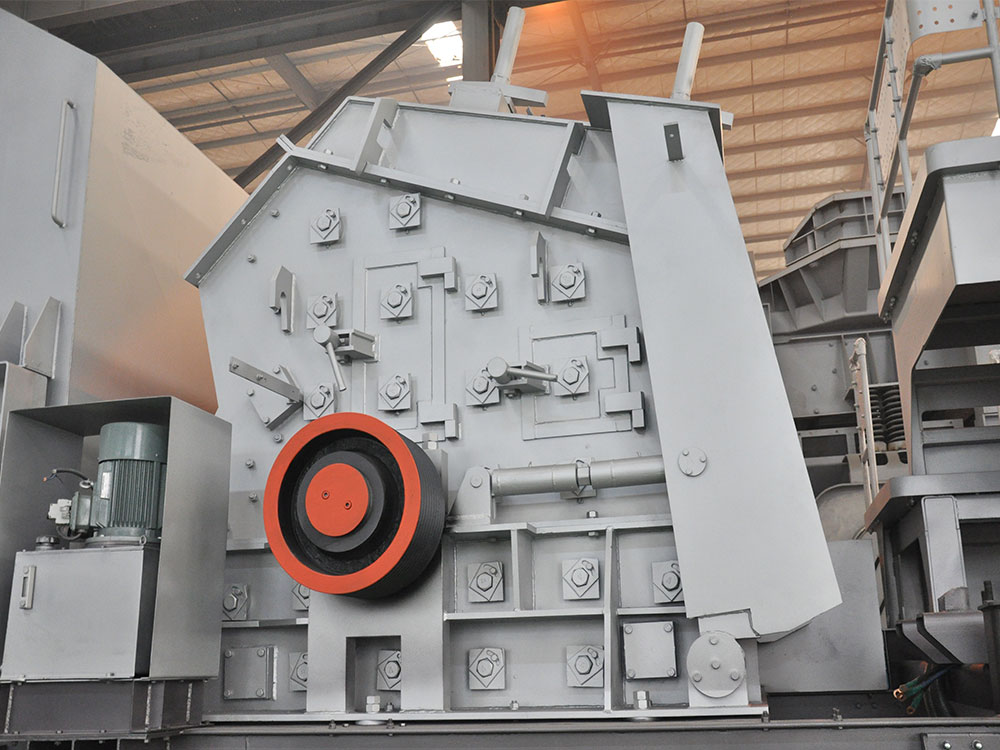

In the cone crusher performance is superior, mainly is suitable for the broken and finely homework, thus product particle size and more uniform. Cone crushing cavity design diversity, the user can according to different requirements, choose different cavity type, among them, the standard is suitable for the crusher cavity type, medium is suitable for fine grinding, short head type is used in fine grinding. The jaw crusher is designed for various hardness of rock crushing equipment, mainly is suitable for the coarse crushing and crusher. Jaw crusher in the crushing cavity consists of two piece of jaw, moving jaw and static jaw, mainly through two jaw curve move and extrusion materials, broken when the moving jaw near static jaw plate, the material is crush; When the moving jaw from static jaw plate, has broken material from crushing cavity mouth eduction. Due to the strong jaw crusher broken, simple operation, at present has been widely used in mineral processing, building materials, silicate and ceramic industries.

In simple terms, jaw crusher is mainly used for a broken, broken stone relatively large; Cone crusher is used for crushing medium stones, usually for secondary crushing. The same is yudu is for material with extrusion. The broken degree is related to their structure and working principle. Cone crusher is rotary oscillation, dynamic cone rotating at the same time do the eccentric swing drive the cone plate with fixed plate extrusion materials; Pendulum jaw crusher is Jane and compound pendulum, driven by moving jaw plane fixed jaw jaw and a reciprocating extrusion exercise to broken material. In short, the former is do swings to broken, trajectory is a circle around; While the latter is broken do reciprocating swing, squeezing movement is a straight line. Compared to the jaw crusher, cone crusher work process is continuous, material in the cavity of force is a bending force, shear force and friction force, so easy to be broken. Therefore, cone crusher production capacity is large, low power consumption.

Liming heavy industry production of crusher variety, welcome consulting service to choose.