For a limestone classic stone production line with a designed capacity of 100 tons per hour, the configuration is jaw crusher, impact crusher and vibrating screen. This production line plays a vital role in the mining and construction materials industries. Based on a number of rigorously screened and verified high-credibility information, we have made an in-depth summary and analysis of its core configuration and key points.

Analysis of key equipment selection

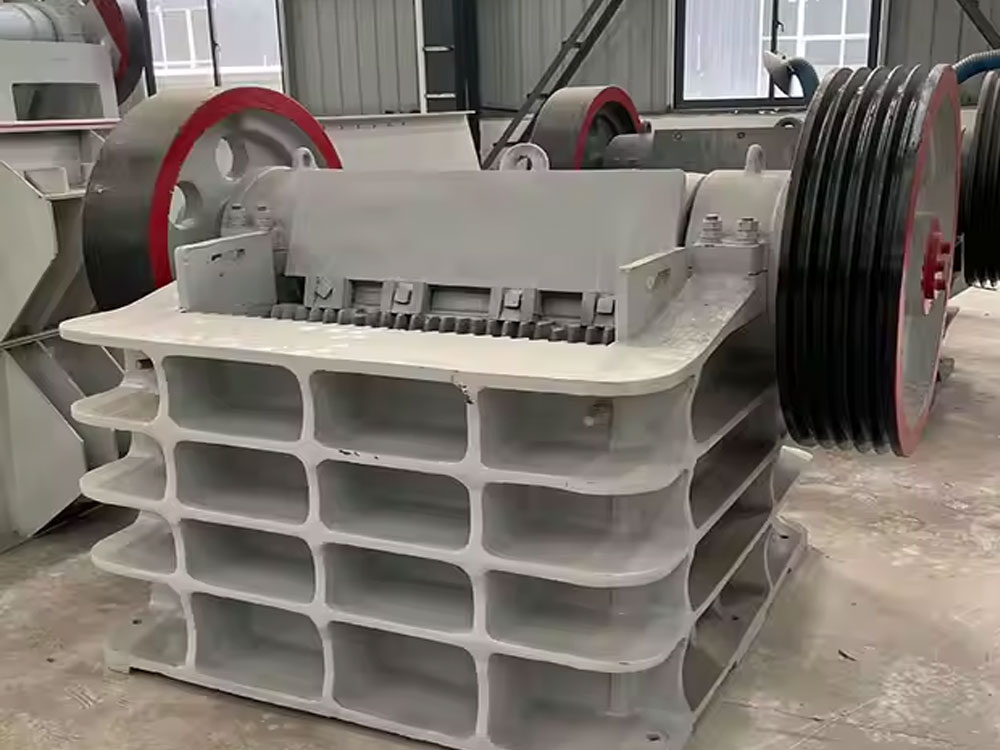

Coarse crushing core: Jaw crusher

In the coarse crushing stage, the Model 69 Jaw Crusher (PE-600×900 model, for example) is the first choice for its excellent performance. The capacity of this crusher ranges from 50 to 160 tons/hour, easily meeting the production target of 100 tons/hour. Its wide feed opening is designed to accommodate large limestone raw materials, thus improving production efficiency. Meanwhile, the efficient crushing ratio ensures that the raw materials are effectively crushed in a short time. In addition, the easy maintenance design greatly reduces downtime and improves overall equipment reliability.

Optimization of medium and fine crushing: impact crusher

The PF1214 impact crusher plays a key role in medium and fine crushing. It is responsible for further refining the material processed by the jaw crusher, and through precise regulation, it can ensure that the finished product size reaches the specified range, such as 10-40mm. the impact crusher is based on the working principle of impact crushing, which makes the finished product particle shape show three-dimensionality and fullness, which is crucial for the high-standard aggregates market. It is especially suitable for handling limestone with low to medium hardness (≤200MPa), and its crushing effect is even more remarkable.

Screening refinement: vibrating screen

Vibrating screens (e.g. model 3YK2460 or 1854), as the screening equipment in the production line, adopt a multi-layer screen layout. This design is able to accurately grade different sizes of finished products, such as 5-10mm, 10-20mm, 16-31.5mm, etc. At the same time, the built-in closed-circuit recycling mechanism enables the over-sized materials to be returned to the impact crusher for re-processing, thus ensuring the high stability of the overall finished product rate.

Auxiliary Facilities and Process Highlights

Overview of Auxiliary Facilities

Vibrating Feeder: The ZSW380×95 model vibrating feeder ensures that the material is fed into the jaw crusher in an even and stable manner. This uniform feeding method effectively prevents the risk of clogging and improves the continuity and stability of the production line.

Belt Conveyor: As the link of material transfer, the belt conveyor connects all parts of the production line. Its efficient and stable transfer capacity ensures the smooth operation of the production line.

Dedusting system: In order to reduce the dust emission during the production process, the production line is equipped with an advanced dedusting system. This system effectively meets the requirements of environmental regulations and protects the health of employees.

Process Features Explained

Economical and Efficient: Compared with the cone crusher solution, the combination of jaw crusher and impact crusher is more economical in terms of initial investment. In addition, since these two types of equipment are relatively simple in structure, the later maintenance cost is also relatively low. This gives the production line a significant advantage in cost control.

Aesthetic particle shape: The impact crushing method of the impact crusher gives the finished product a good particle shape performance. This aesthetically pleasing grain shape meets the high demands of the high standard aggregate market for finished product quality. In practice, the aggregates produced by this production line are widely used in concrete, asphalt and other building materials.

Wide applicability: The production line has a strong inclusiveness to the limestone hardness range (medium and low hardness is the best). At the same time, it is able to directly process raw materials with a block size of up to 500mm. This versatility allows the line to perform well in different regions and under different raw material conditions.

This limestone classic stone production line with a designed capacity of 100 tons per hour shows excellent performance and advantages in terms of key equipment selection, auxiliary facilities configuration and process features. It not only meets the demand for efficient and stable production, but also conforms to the development trend of environmental protection and economy. This production line will continue to play an important role in the future mining and building materials industry.