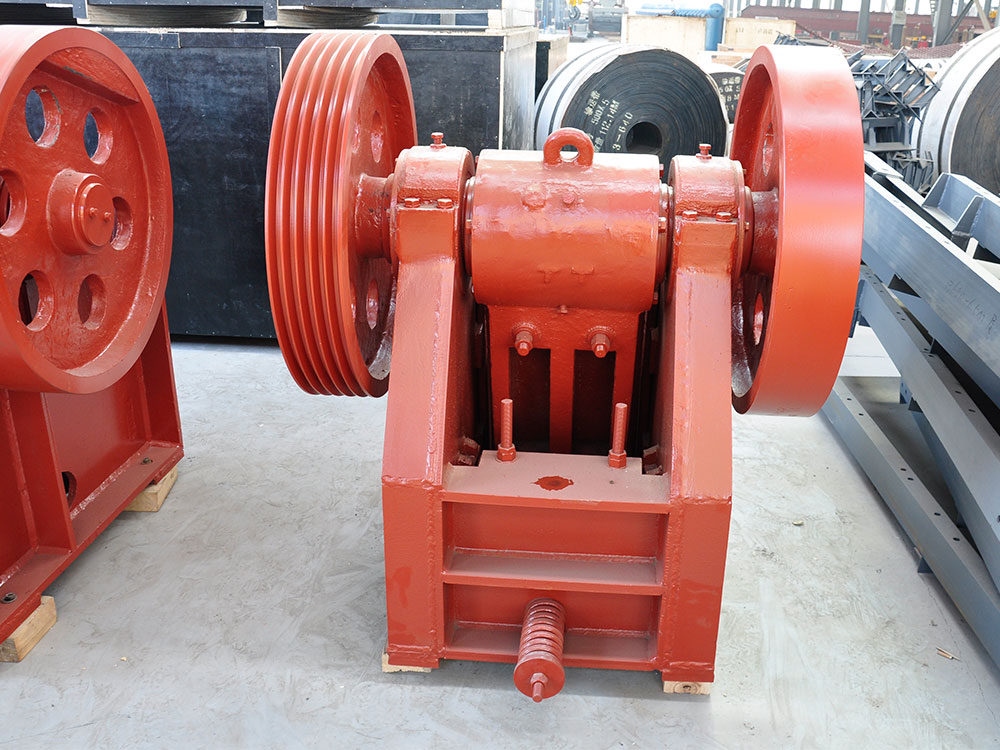

In the development and utilization of mineral resources, the crushing and processing of iron ore is a crucial link. As a key equipment widely used in mining, metallurgy, building materials and other industries, the processing capacity of PE-750×1060 jaw crusher is directly related to production efficiency and economic benefits. This article will comprehensively analyze the processing capacity of PE-750×1060 jaw crusher in the iron ore crushing scenario, and deeply analyze the key parameters to provide valuable reference for relevant practitioners.

1. Overview of core parameters and basic performance

Under the standard working conditions of limestone, the theoretical output of PE-750×1060 jaw crusher is 110-320 tons/hour, which provides us with a basic output expectation. However, in the iron ore crushing scenario, due to the high hardness (Mohs hardness 5.5-6.5) and abrasiveness of iron ore, its actual output is usually affected to a certain extent. According to practical experience, the actual output of iron ore is usually 70%-80% of the theoretical value, that is, about 77-256 tons/hour. If the proportion of large ore in the feed exceeds 30%, the output may further drop to 60%-70% of the theoretical value, or about 66-224 tons/hour, due to the increased difficulty of crushing.

In order to more intuitively understand the daily output of the equipment, we can calculate it based on a single shift of 8 hours per day. Under normal circumstances, the average daily processing capacity is about 616-2048 tons. But please note that this data also needs to be considered in combination with factors such as the operating stability of the equipment, maintenance status, and the skill level of the operator.

2. Applicability analysis and optimization strategy for iron ore crushing Advantages and features PE-750×1060 jaw crusher shows many advantages in iron ore crushing scenarios. Its deep V-shaped crushing chamber design effectively reduces the blocking phenomenon, and is particularly suitable for the crushing of flaky or blocky iron ore. In addition, the equipment uses high manganese steel jaw plates, which have a wear resistance that is more than 3 times higher than that of ordinary materials, greatly extending the service life. Some manufacturers also provide dual-motor drive solutions (such as 2×55kW), which enhances torque output, can better cope with sudden hard rock situations, and ensure stable operation of the production line.

Production constraints

Although the PE-750×1060 jaw crusher has many advantages in iron ore crushing, its output is still restricted by some factors. First, material properties are one of the key factors affecting output. When the silicon content of iron ore exceeds 15%, it will accelerate the wear of the jaw plate, resulting in a decrease in production capacity. Secondly, operating specifications also have an important impact on output. Although increasing the discharge port can increase output, the finished product particle size will also become coarser (>150mm), so a trade-off needs to be made between process requirements. In addition, the selection of supporting equipment is also crucial. The front vibrating feeder can improve the uniformity of the feed, help avoid empty collisions or overloads, and thus improve the processing capacity of the equipment.

III. Selection recommendations and on-site application guidance

Model selection

For small and medium-sized production lines, the PE-750×1060 jaw crusher is undoubtedly a cost-effective choice. Compared with the production limit of 16-64 tons/hour of small equipment such as PE-400×600, PE-750×1060 has more advantages in iron ore crushing. However, for large production lines, if the target daily output exceeds 3,000 tons, it is necessary to consider matching larger equipment, such as PE-1500×1800 (500-1000 tons/hour) or CJ European version jaw crusher, etc., to meet higher production needs.

Operation and maintenance management

Under iron ore conditions, the operation and maintenance management of the PE-750×1060 jaw crusher is crucial. It is recommended to check the wear of the jaw plate every 200 hours. If the depth of the dent exceeds 15mm, it should be replaced in time to avoid affecting the output and product quality. At the same time, the temperature change of the eccentric shaft bearing should be closely monitored. When the temperature exceeds 80℃, the machine needs to be shut down and the cavity needs to be cleared to prevent iron ore debris from getting stuck and causing equipment damage. In addition, since the vibration intensity generated by iron ore crushing is higher than that of limestone crushing, the concrete foundation needs to increase the reinforcement by 20% to improve stability.

Efficiency Improvement Suggestions

In order to improve the efficiency of PE-750×1060 jaw crusher in iron ore crushing, it is recommended to give priority to models equipped with hydraulic wedge block discharge port adjustment system (such as CJ series). This model can greatly shorten the time for iron ore particle size adjustment, thereby improving the flexibility and efficiency of the production line. At the same time, it is also possible to consider using intelligent control systems to remotely monitor and diagnose faults on the equipment, so as to timely discover and solve problems and ensure the stable operation of the production line.

Case Analysis

Take an iron ore processing plant as an example. The plant uses PE-750×1060 jaw crusher to crush iron ore. In the early stage of production, due to the lack of understanding of the equipment performance by the operators, the output was unstable and the wear was serious. Later, the plant gradually mastered the operation rules of the equipment through measures such as strengthening training, optimizing operating procedures, and regular maintenance and inspection. At the same time, they also dynamically adjusted the discharge port according to actual needs, and adopted an intelligent control system for remote monitoring. The implementation of these measures has significantly improved the iron ore crushing efficiency of the plant, stabilized the output at about 200 tons/hour, and effectively controlled the wear of the equipment.

Data Comparison

Compared with similar equipment, the PE-750×1060 jaw crusher shows higher cost performance and efficiency in iron ore crushing. Taking a certain brand of PE-600×900 jaw crusher as an example, its theoretical output in iron ore crushing is 80-220 tons/hour, but the actual output is often lower than this range. However, the actual output of the PE-750×1060 jaw crusher under the same working conditions can be stabilized between 77-256 tons/hour, and it has stronger wear resistance and more stable operation. In addition, in terms of price, the PE-750×1060 jaw crusher is also in the mainstream price range (300,000-400,000 yuan), with a high cost-effectiveness.

In summary, the PE-750×1060 jaw crusher shows good processing capacity and applicability in the iron ore crushing scenario. When planning the iron ore crushing production line, we should plan according to the lower and middle limit capacity (77-200 tons/hour), and focus on the configuration of high manganese steel jaw plates and the dynamic regulation of the discharge port. At the same time, strengthening operation and maintenance management, adopting intelligent control systems, and optimizing operating procedures are also key to improving equipment efficiency. In the mainstream price range of 300,000-400,000 yuan, it is recommended to choose a model with dual motor drive + hydraulic adjustment to balance cost and durability.